Composite material air release valve plate for compressor and preparation method thereof

A discharge valve plate and composite material technology, applied in the field of compressors, can solve problems such as large running resistance, difficulty in improving compressor performance, and heavy weight of metal exhaust valve plates, so as to improve impact resistance and fatigue performance, and bend Improvement of fatigue life and elimination of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The raw material used for the composite material exhaust valve plate of the compressor in the present invention is special engineering plastics, and its material ratio is: polyetheretherketone (PEEK)+(1~30)wt% carbon fiber, and the valve plate thickness of injection molding: 0.5~ 1.0mm; the material has good properties: ①high temperature resistance; ②wear resistance; ③corrosion resistance; ④self-lubrication; ⑤flame retardancy; ⑥hydrolysis resistance.

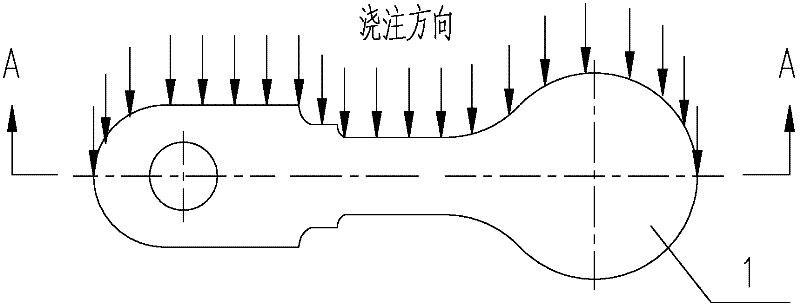

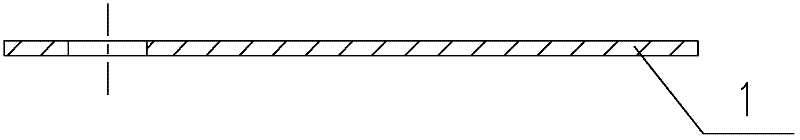

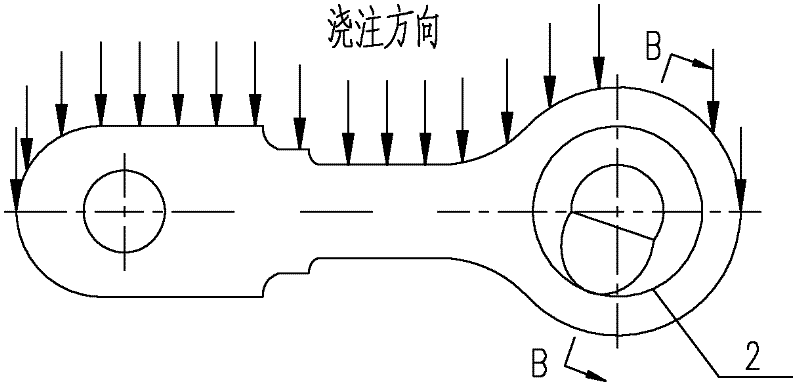

[0040] According to the actual situation, the above-mentioned composite material can be processed into the same flat shape as the metal valve plate ( figure 1 , 2 ), and the exhaust valve can also be injection-molded into a special structure that is beneficial to the performance of the compressor, such as: spoon-shaped ( Image 6 , 7 ) or a shape with bosses ( image 3 , 4 , 5), which can reduce the clearance volume at the vent hole, and improve the performance of the whole machine. Metal valve plates do not have such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com