High-performance thermoelectric composite material and preparation method thereof

A composite material and thermoelectric technology, which is applied in the direction of thermoelectric device node lead-out material, thermoelectric device manufacturing/processing, etc. The effect of improving thermoelectric performance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

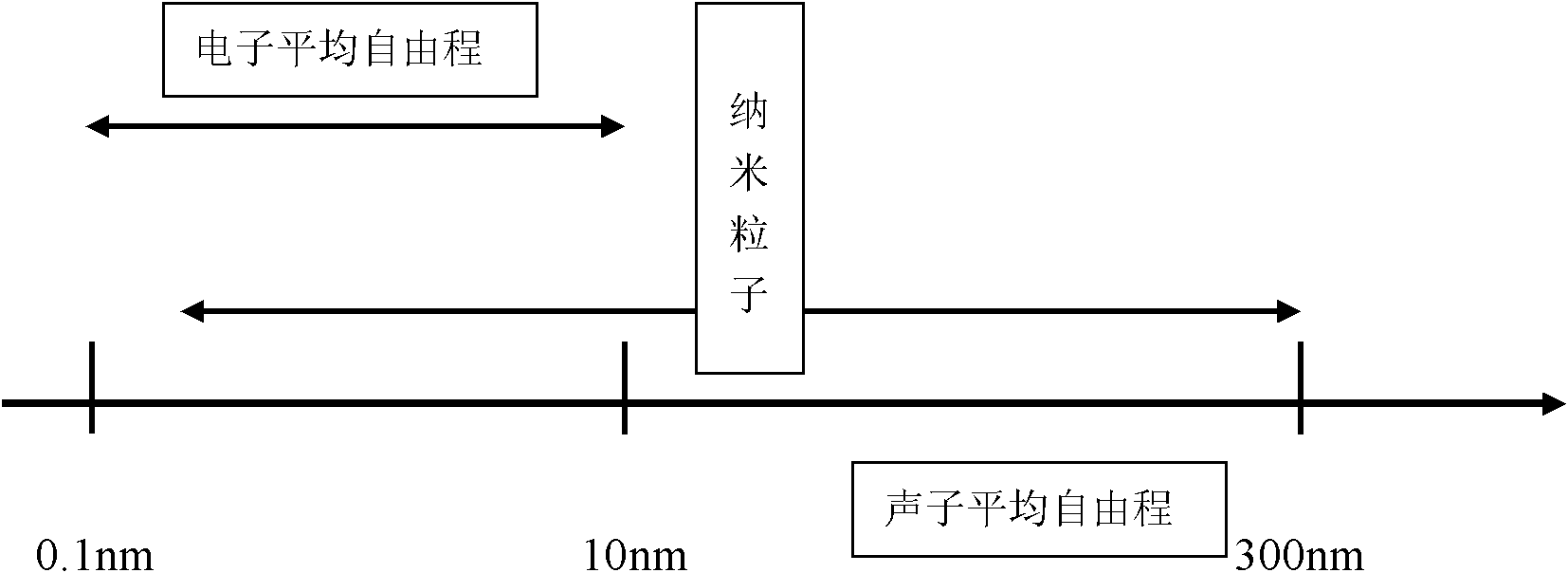

Problems solved by technology

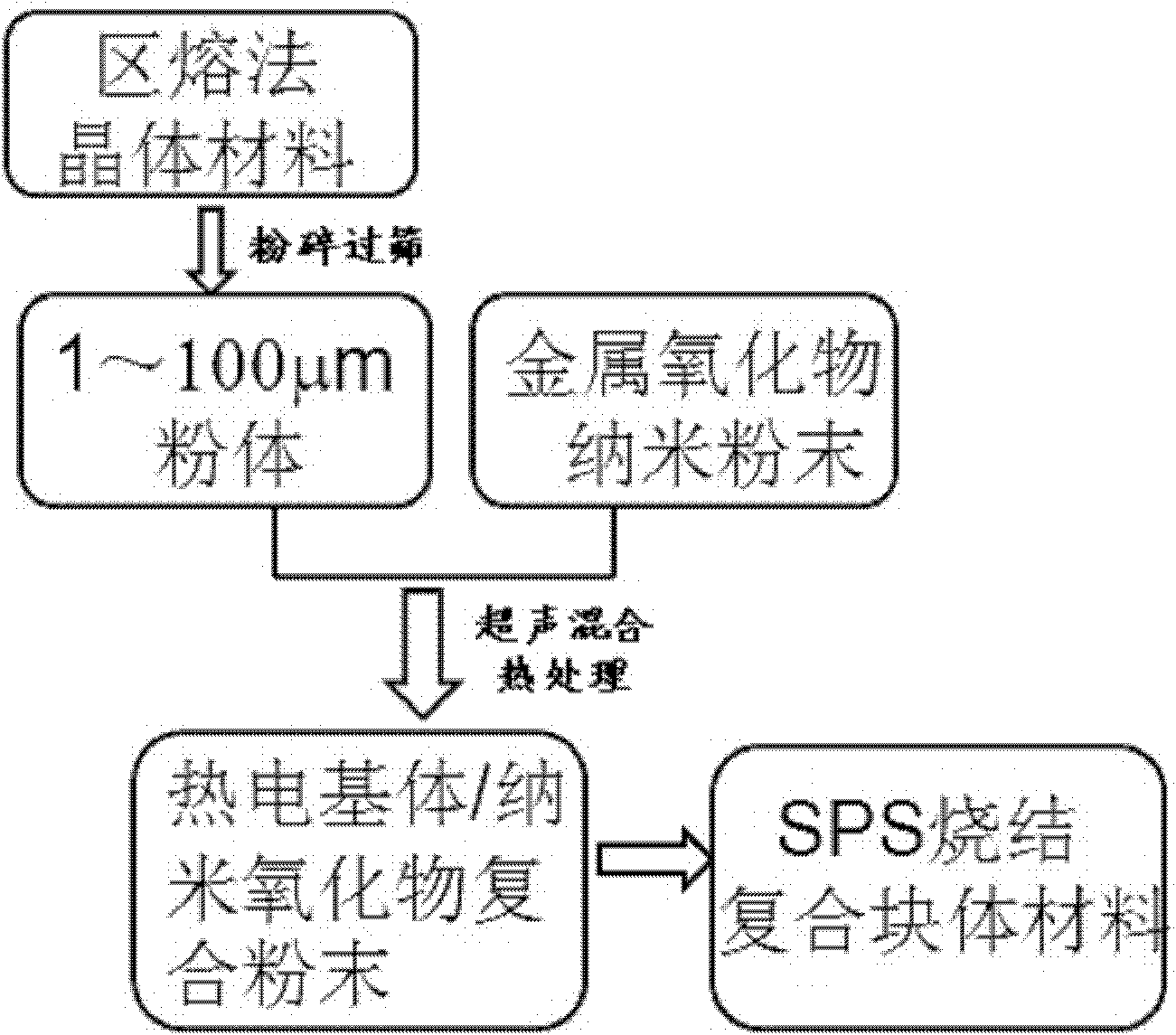

Method used

Image

Examples

Embodiment 1

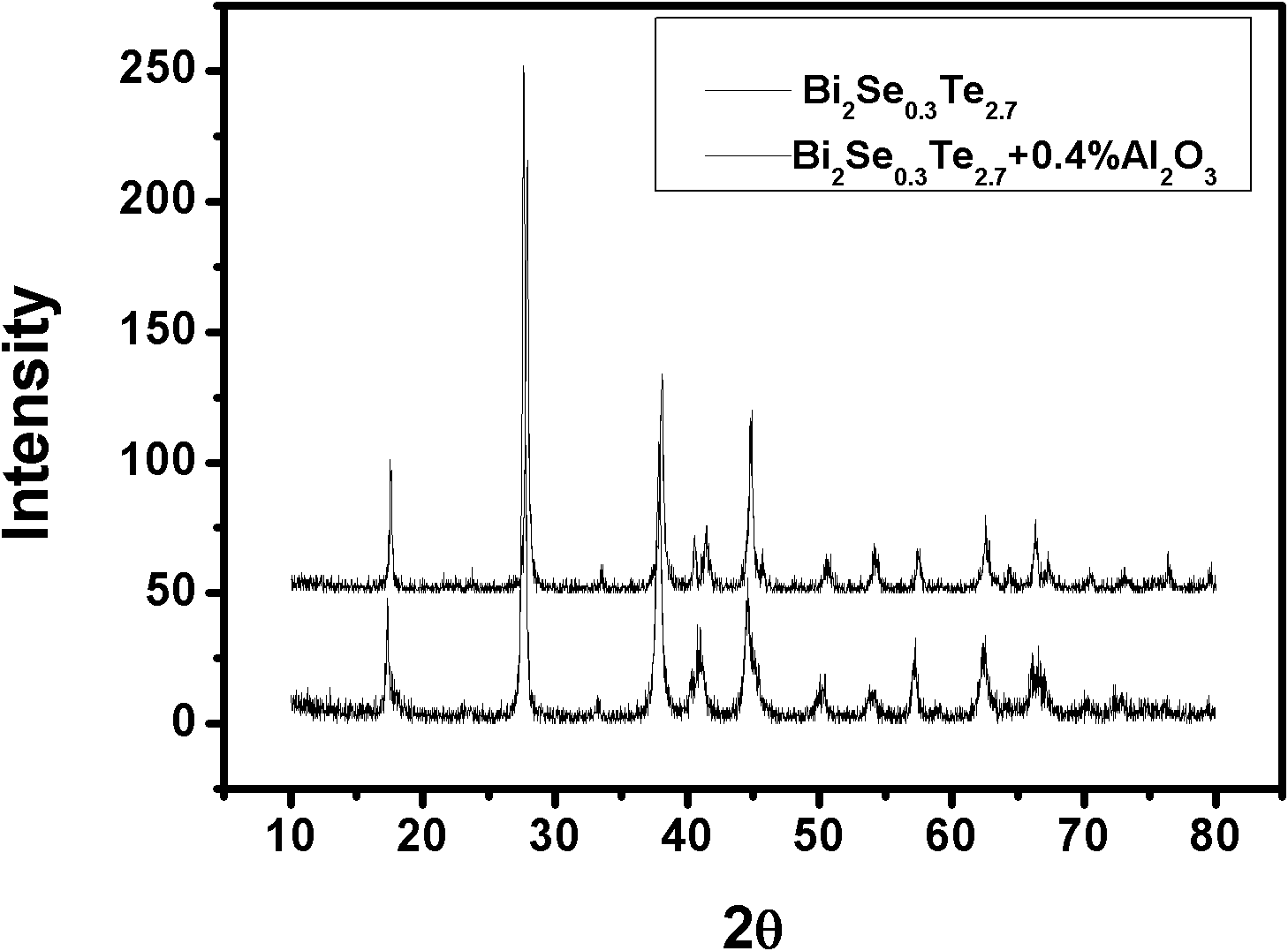

[0030] Embodiment 1: component is Bi 2 Se 0.3 Te 2.7 n-type matrix powder

[0031] Firstly, oriented polycrystalline rods of the above components were obtained by zone melting growth. The zone melting growth conditions were melting temperature 700°C, temperature gradient 25°C / mm, and growth rate 2.5mm / h. After the surface part of the polycrystalline rod is removed, it is crushed and sieved, and a steel container is used as a crushing tool, and the crushing process is protected by an inert atmosphere such as argon. After crushing, use a standard nylon sieve to sieve the powder to obtain the initial powder with the required particle size distribution, and select the powder with a particle size of 1-100 μm.

[0032] Using a graphite mold, SPS sintering was performed under vacuum conditions. The sintering temperature is 440°C, the heating rate is 100°C / min, the holding time is 10min, and the applied pressure is 60MP. The bending strength of the obtained sintered body is close...

Embodiment 2

[0033] Embodiment 2: component is Bi 2 Se 0.3 Te 2.7 n-type matrix powder+0.4wt.%Al 2 o 3 nano powder

[0034] Firstly, oriented polycrystalline rods of the above components were obtained by zone melting growth. The zone melting growth conditions were melting temperature 700°C, temperature gradient 25°C / mm, and growth rate 2.5mm / h. After the surface part of the polycrystalline rod is removed, it is crushed and sieved, and a steel container is used as a crushing tool, and the crushing process is protected by an inert atmosphere such as argon. After crushing, use a standard nylon sieve to sieve the powder to obtain the initial powder with the required particle size distribution, and select the powder with a particle size of 1-100um.

[0035] Ultrasonic mixing of the matrix powder and metal oxide nanopowder obtained above, the liquid medium used for ultrasonic mixing is ethanol solution, polyethylene glycol is used as a dispersant, and ultrasonic mixing is performed for 0.5h...

Embodiment 3

[0037] Embodiment 3: component is Bi 2 Se 0.3 Te 2.7 n-type matrix powder+0.2wt.%Al 2 o 3 nano powder

[0038] Firstly, oriented polycrystalline rods of the above components were obtained by zone melting growth. The zone melting growth conditions were melting temperature 650°C, temperature gradient 20°C / mm, and growth rate 3mm / h. After the surface part of the polycrystalline rod is removed, it is crushed and sieved, and a steel container is used as a crushing tool, and the crushing process is protected by an inert atmosphere such as argon. After crushing, use a standard nylon sieve to sieve the powder to obtain the initial powder with the required particle size distribution, and select the powder with a particle size of 1-100um.

[0039] Ultrasonic mixing of the matrix powder and metal oxide nano-powder obtained above, the liquid medium used for ultrasonic mixing is ethanol, polyethylene glycol is used as a dispersant, and ultrasonic mixing is carried out for 2 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com