Dyeing anode oxidization method of silicon bronze casting aluminum alloy

A cast aluminum alloy, anodic oxidation technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems such as difficult to determine the pulse parameters, flow marks, unclear effect, etc., to achieve stable current rise and reduce flow scars, noticeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is to illustrate the application of the present invention in dyed anodic oxidation of silicon-copper cast aluminum alloy.

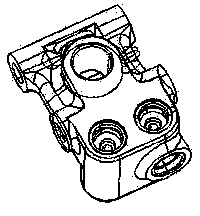

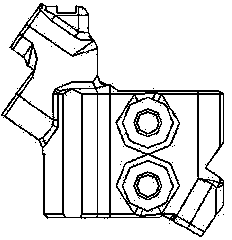

[0030] ①Preparation of samples: such as figure 1 It is a hydraulic valve body used in the car roof tilting system. It is made of cast aluminum A380 and requires black anodizing. The machined workpiece is placed in a vibration grinder for 20 minutes of vibration grinding.

[0031] ②Hang up the ground product, degrease, and ensure that the product is in full contact with the hanger when hanging.

[0032] ③ Put the degreased product into the stain removal solution (nitric acid: 50±5%, hydrofluoric acid: 2-3%, the rest of the ingredients are water, the above ratios are volume ratios) for treatment, the temperature is normal temperature, and the treatment time is 5 ~6 minutes.

[0033] ④ Anodizing bath preparation and anodizing treatment: Anodizing bath preparation, the anodizing bath is sulfuric acid oxidation bath, wherein the concen...

Embodiment 2

[0040] This embodiment is to illustrate the application of the present invention in dyed anodic oxidation of silicon-copper cast aluminum alloy.

[0041] ①Preparation of samples: such as figure 1 It is a hydraulic valve body used in the car roof tilting system. Its material is cast aluminum A380, which requires black anodizing. Put the machined workpiece into the vibration grinding machine for vibration grinding for 30 minutes.

[0042] ②Hang up the ground product, degrease, and ensure that the product is in full contact with the hanger when hanging.

[0043] ③ Put the degreased product into the stain removal solution (nitric acid: 50±5%, hydrofluoric acid: 2-3%, the rest of the ingredients are water, the above ratios are volume ratios) for treatment, the temperature is normal temperature, and the treatment time is 5 minute.

[0044] ④ Anodizing bath preparation and anodizing treatment: Anodizing bath preparation, the anodizing bath is sulfuric acid oxidation bath, wherein t...

Embodiment 3

[0051] This embodiment is to illustrate the application of the present invention in dyed anodic oxidation of silicon-copper cast aluminum alloy.

[0052] ①Preparation of samples: such as figure 1 It is a hydraulic valve body used in the car roof tilting system. It is made of cast aluminum A380 and requires black anodizing. The machined workpiece is placed in a vibration grinder for 25 minutes of vibration grinding.

[0053] ②Hang up the ground product, degrease, and ensure that the product is in full contact with the hanger when hanging.

[0054] ③ Put the degreased product into the stain removal solution (nitric acid: 50±5%, hydrofluoric acid: 2-3%, the rest of the ingredients are water, the above ratios are volume ratios) for treatment, the temperature is normal temperature, and the treatment time is 5 minute.

[0055] ④ Anodizing bath preparation and anodizing treatment: Anodizing bath preparation, the anodizing bath is sulfuric acid oxidation bath, wherein the concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com