Prism fine polishing device and process

A technology of fine polishing and prism, which is applied in the direction of grinding/polishing equipment, metal processing equipment, manufacturing tools, etc. It can solve the problems that the surface shape of optical components is not easy to guarantee, achieve high appearance level, improve surface shape accuracy, and improve polishing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

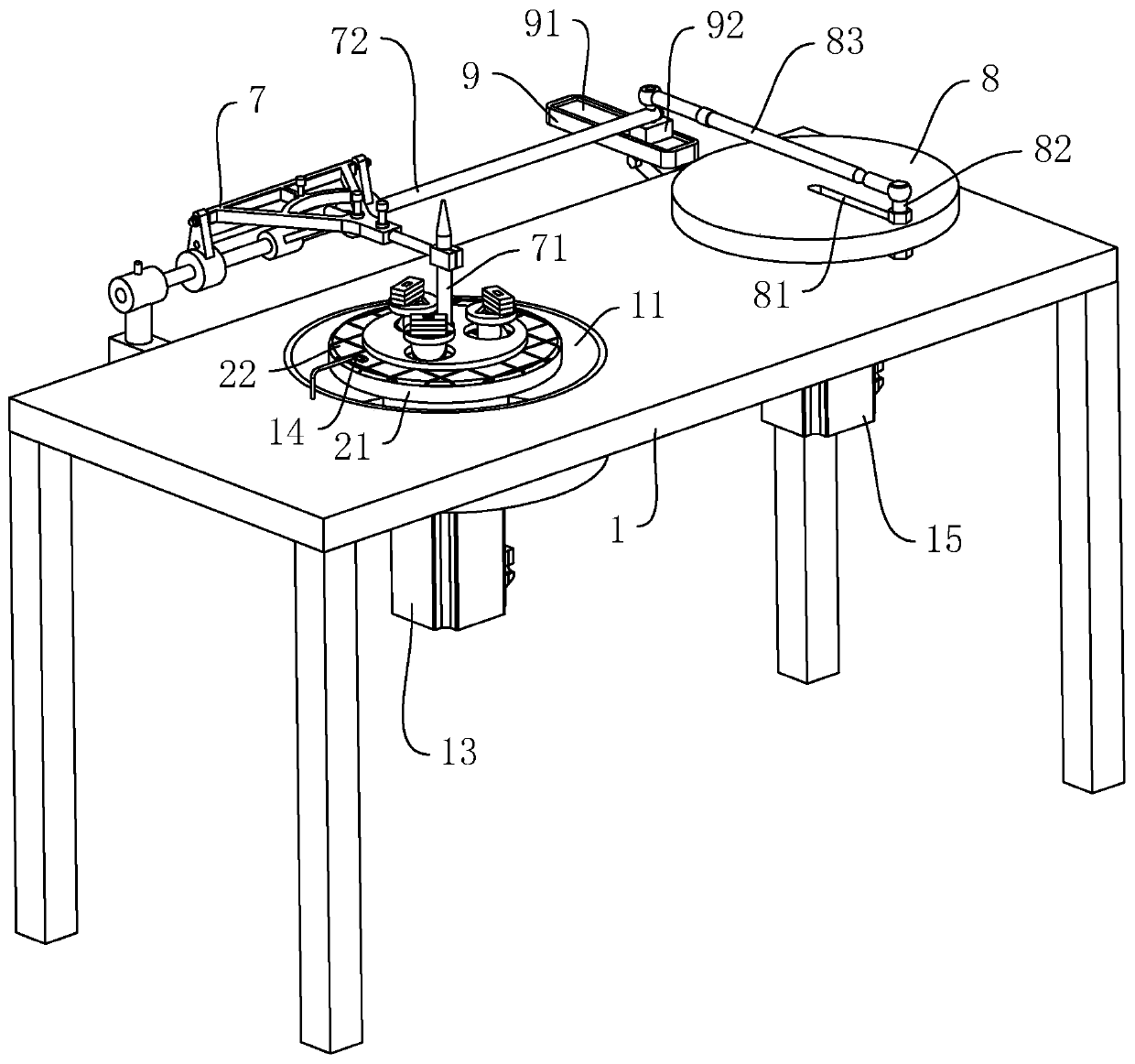

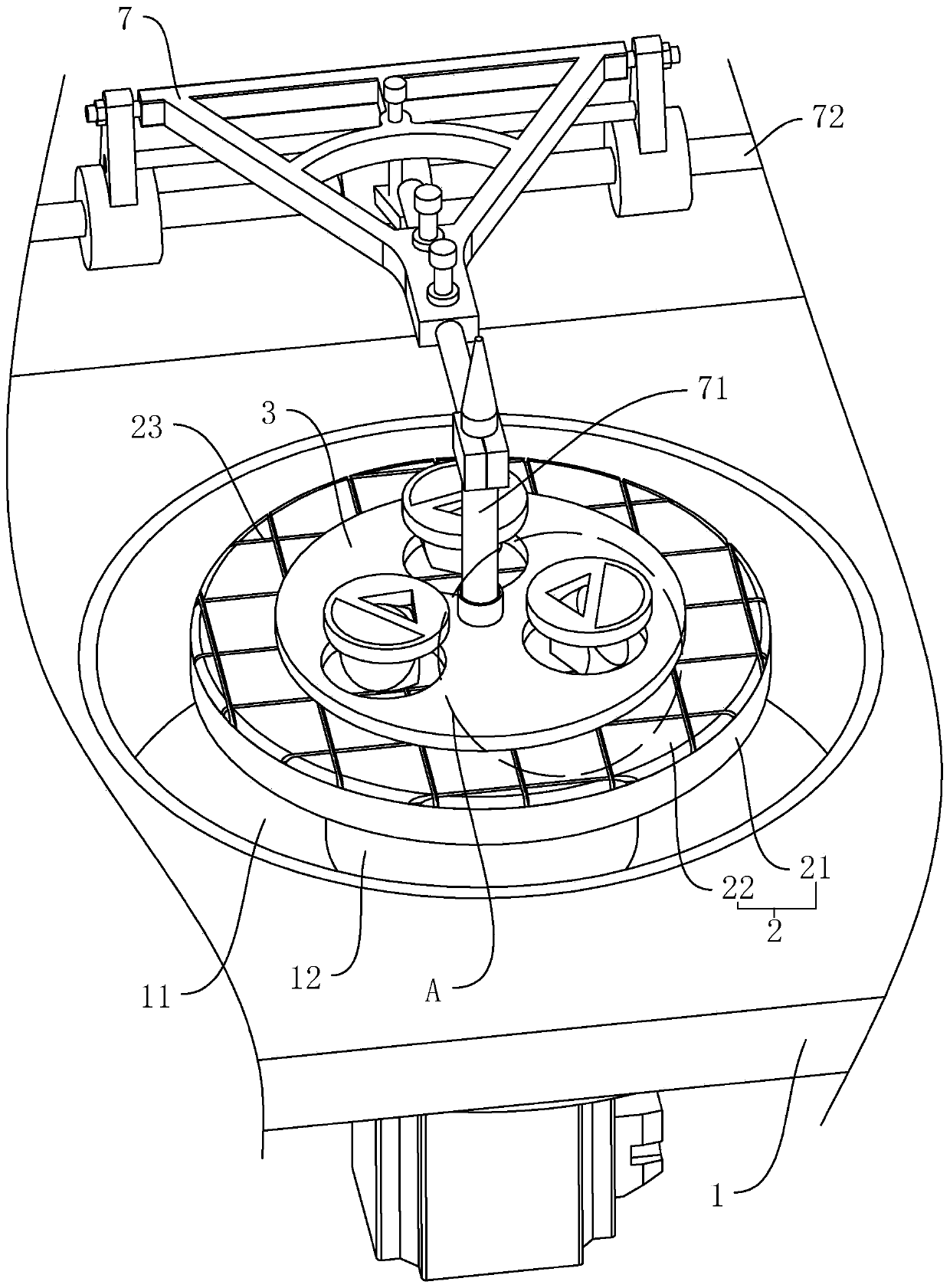

[0045] refer to figure 1 and figure 2, is a prism fine polishing device disclosed in the present invention, comprising a frame 1 and a polishing assembly arranged on the frame 1 . The polishing assembly includes a polishing liquid pool 11 for storing polishing liquid provided on the top surface of the frame 1, and the frame 1 is also provided with a spray assembly for spraying the polishing liquid. The shower assembly includes a shower head 14 arranged on the top surface of the frame 1 , and the shower head 14 is located above the polishing disc 2 . The polishing liquid is sprinkled on the polishing disc 2 by pressurizing the water pump to realize heat radiation and cooling of the polishing disc 2 . The supply of polishing liquid also affects the polishing speed. If the supply is too much, the heat generated by polishing will be dissipated rapidly, which is not conducive to the hydrolysis reaction, and the consistency between the mold and the surface of the prism is poor; i...

Embodiment 2

[0052] A kind of prism fine polishing process, it realizes the fine polishing of optical element 6 based on a kind of prism fine polishing equipment in embodiment one, comprises the following steps:

[0053] Step 1: Turn on the spray assembly, spray the polishing solution on the surface of the polishing disc 2 from the nozzle 14, the pH value of the polishing solution is 6.5, and the temperature of the polishing solution is 30°C;

[0054] According to the mass ratio, the content of each component of the polishing liquid is shown in the following table:

[0055] Table 1. Contents of each component of polishing fluid

[0056] components Ceria water Zinc nitrate 10kg 89.5kg 0.5kg

[0057] The polishing liquid can reduce the temperature of the surface of the polishing disc and dissipate the heat generated by polishing. In addition, the polishing powder particles in the polishing liquid can participate in the polishing, which improves the polishing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com