Silicate luminescent material and preparation method thereof

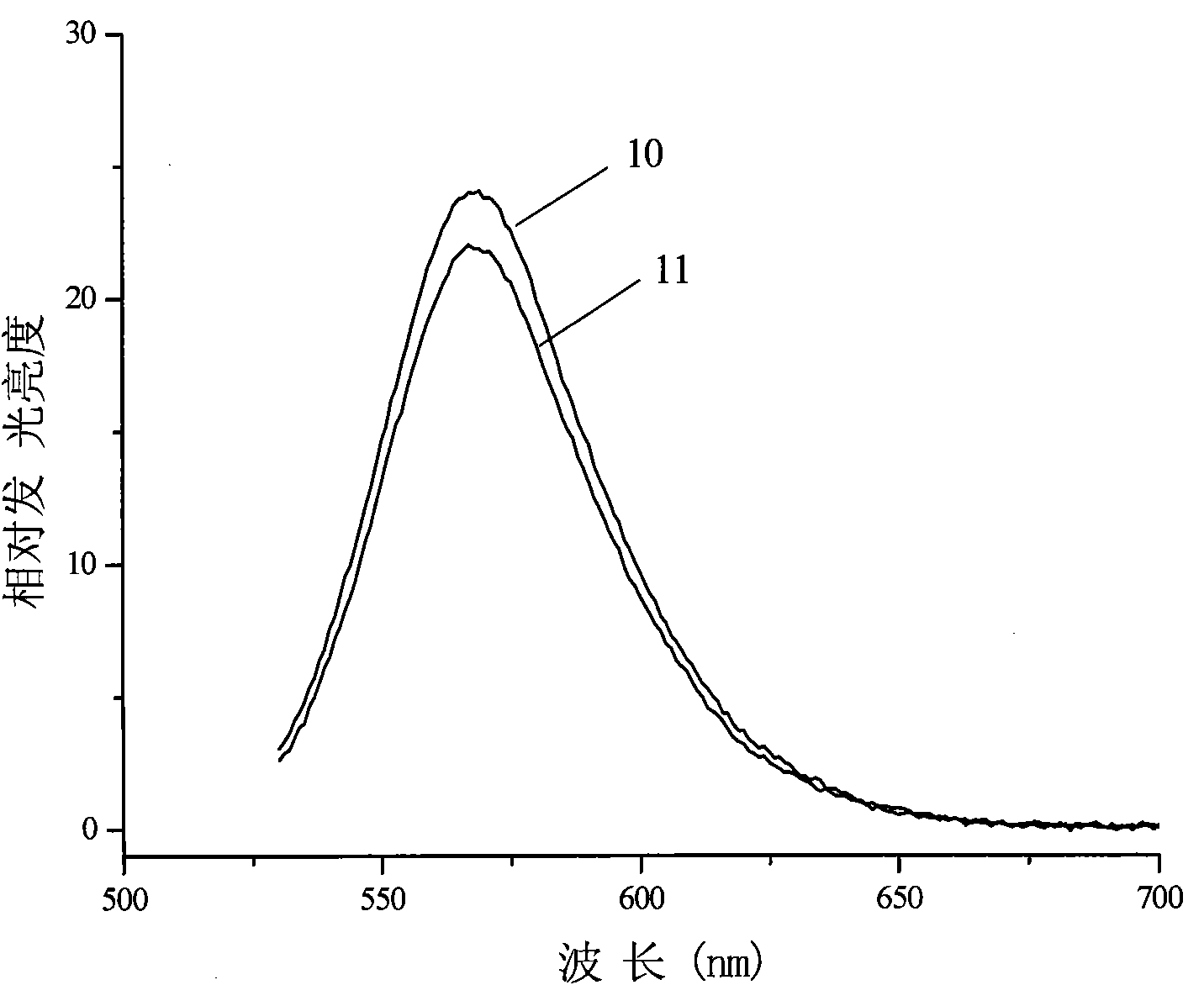

A technology of luminescent materials and silicates, applied in the directions of luminescent materials, chemical instruments and methods, etc., can solve the problems of low color rendering of white LEDs and the need for further improvement of luminous brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the above-mentioned silicate luminescent material can be a high-temperature solid-phase method, which includes the following steps:

[0021] (1) Preparation of silica airgel containing M particles. A certain amount of silicon aerogel can be weighed and dissolved in the ethanol solution containing the M raw material, stirred at 50-75°C for 0.5-3 hours, then ultrasonically treated for 10 minutes, and then dried at 60-150°C. Grind evenly, and calcinate at 600-1300° C. for 0.5-3 hours to obtain silicon airgel containing M particles. Wherein, the silica airgel used has a pore diameter of 20-100 nanometers and a porosity of 92-98%. M raw material is AgNO 3 , HAuCl 4 , HPtCl 4 One or M of the nano colloidal particles.

[0022] (2) According to the composition formula (Sr 1-y A y ) 3-x SiO 5 :Eu x ,M z The stoichiometry of Sr, A, Eu is weighed and the silica airgel containing M particles synthesized in step (1) is mixed uniformly. Wherein A...

Embodiment 1

[0025] Embodiment 1 high temperature solid-phase method prepares (Sr 0.9 Ba 0.1 ) 2.92 SiO 5 :Eu 0.08 , Pt 0.001 .

[0026] First weigh 0.3g of silica airgel, dissolve it to 5ml containing HPtCl 4 1×10 -3 mol / L ethanol solution, stirred at 50°C for 3 hours, then ultrasonicated for 10 minutes, and then dried at 60°C, the dried sample was ground evenly, and pre-calcined at 600°C for 3 hours. Then weigh the SrC 2 o 4 1.8463g, BaC 2 o 4 0.2632g, Eu 2 (CO 3 ) 3 0.0774g and Ag-containing silica airgel 0.2404g were mixed evenly, and then in 95% N 2 +5%H 2 Sintering at 1200°C for 10 hours under a weak reducing atmosphere, and cooling the obtained product to room temperature to obtain (Sr 0.9 Ba 0.1 ) 2.92 SiO 5 :Eu 0.08 , Pt 0.001 A luminescent material that emits orange-red light under excitation at 470 nm.

Embodiment 2

[0027] Embodiment 2 high temperature solid state method prepares Sr 2.96 SiO 5 :Eu 0.04 , Ag 0.0004 .

[0028] First weigh 0.37g of silica airgel, dissolve it to 20ml containing AgNO 3 1.2×10 -4 mol / L ethanol solution, stirred at 60°C for 2 hours, then ultrasonicated for 10 minutes, then dried at 90°C, ground the dried sample evenly, and pre-calcined at 800°C for 2 hours. Then weigh the SrCO 3 1.7476g, Eu 2 o 3 0.0281g and Ag-containing silica aerogel 0.2404g were mixed evenly, and then in 95% N 2 +5%H 2 Sintering at 1500°C for 4 hours under a weak reducing atmosphere, and the resulting product was cooled to room temperature to obtain Sr 2.96 SiO 5 :Eu 0.04 , Ag 0.0004 A luminescent material that emits orange-red light under excitation at 470 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com