Preparation method for high heat resistance polyvinylidene fluoride

A technology of polyvinylidene fluoride and vinylidene fluoride is applied in the field of preparation of high heat-resistant polyvinylidene fluoride, which can solve the problems of PVDF molecular weight distribution, high production cost, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

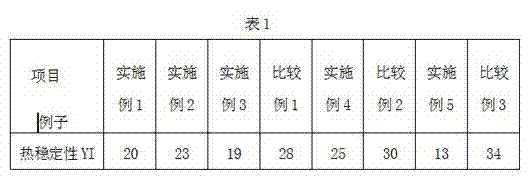

Examples

Embodiment 1

[0039] In a closed polymerization reactor with a capacity of 20L, nitrogen is purged to remove oxygen, so that the oxygen content in the reactor is lower than 50ppm. Add 12Kg deionized water, 3.9g magnesium hydroxide, 1.8g diisopropyl peroxydicarbonate, 50g diethyl malonate, 2.5Kg vinylidene fluoride, raise the temperature to 47°C, turn on the stirring paddle at a speed of 700r / After keeping for 1 hour, slowly add 4.5Kg of vinylidene fluoride to keep the pressure at about 5.6MPa, and at the same time add 15g of diethyl malonate in 3 times at intervals of 40min. After the addition was completed, the insulation polymerization was continued for 2.5 hours, and then the reaction was terminated. Wash the polyvinylidene fluoride slurry with deionized water until the foam disappears, and the conductivity of the washing solution drops below 1 μs / cm, and then vacuum-dry it at 90° C. for 15 hours to obtain a finished product.

Embodiment 2

[0041] In a closed polymerization reactor with a capacity of 20L, nitrogen is purged to remove oxygen, so that the oxygen content in the reactor is lower than 50ppm. Add 12Kg of deionized water, 9.2g of magnesium hydroxide, 145g of diisopropyl peroxydicarbonate, 100g of diethyl malonate, 3.5Kg of vinylidene fluoride, heat up to 60°C, and turn on the stirring paddle at a speed of 500r / min After keeping for 1.5 hours, slowly add 3.8Kg of vinylidene fluoride to keep the pressure at about 6.6MPa, and at the same time add 15g of diethyl malonate in 3 times at intervals of 40min. After the addition was completed, the insulation polymerization was continued for 1.5 hours, and then the reaction was terminated. Wash the polyvinylidene fluoride slurry with deionized water until the foam disappears, and the conductivity of the washing solution drops below 1 μs / cm, and then vacuum-dry it at 96° C. for 18 hours to obtain a finished product.

Embodiment 3

[0043] In a closed polymerization reactor with a capacity of 20L, nitrogen is purged to remove oxygen, so that the oxygen content in the reactor is lower than 50ppm. Add 12Kg deionized water, 10.5g magnesium hydroxide, 60g diisopropyl peroxydicarbonate, 30g diethyl malonate, 3.2Kg vinylidene fluoride, heat up to 66°C, turn on the stirring paddle, and the speed is 620r / min After keeping for 1.1 hours, slowly add 4Kg of vinylidene fluoride to keep the pressure at about 5.6MPa, and at the same time add 10g of diethyl malonate in 3 times at intervals of 40min. After the addition was completed, the insulation polymerization was continued for 2 hours, and then the reaction was terminated. Wash the polyvinylidene fluoride slurry with deionized water until the foam disappears, and the conductivity of the washing solution drops below 1 μs / cm, and then vacuum-dry it at 100° C. for 20 hours to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com