Disposable handle feeling slurry for simulation flowers, as well as preparation method and application of slurry

A technology for hand-feeling pulp and artificial flowers, which is applied in the fields of botanical equipment and methods, application, gardening, etc., can solve the problems of high cost of hand-feeling pulp, poor weather resistance, prolonged production cycle, etc., achieves bright colors and layers, and reduces stickiness. , the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

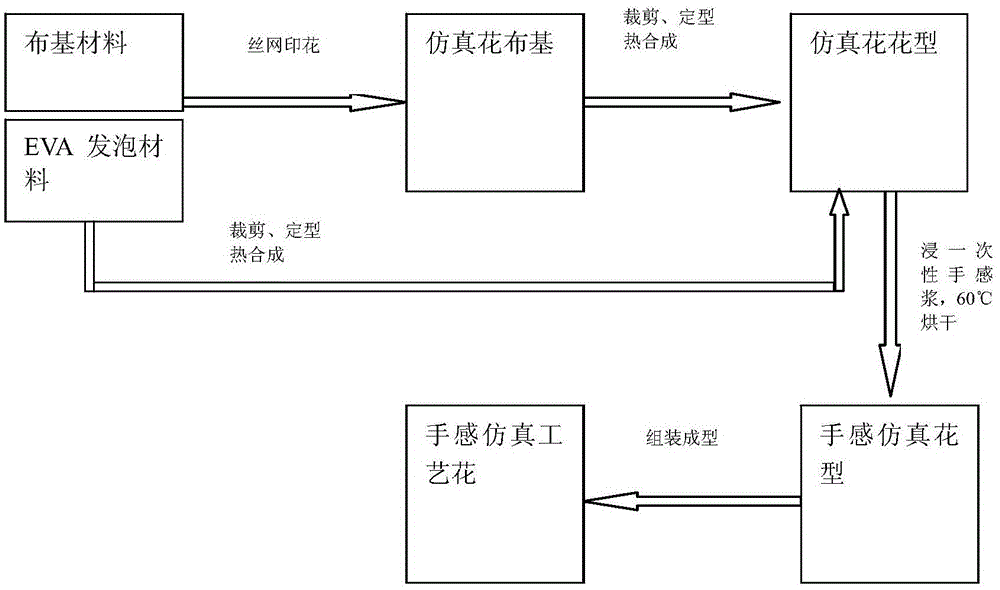

Method used

Image

Examples

preparation example

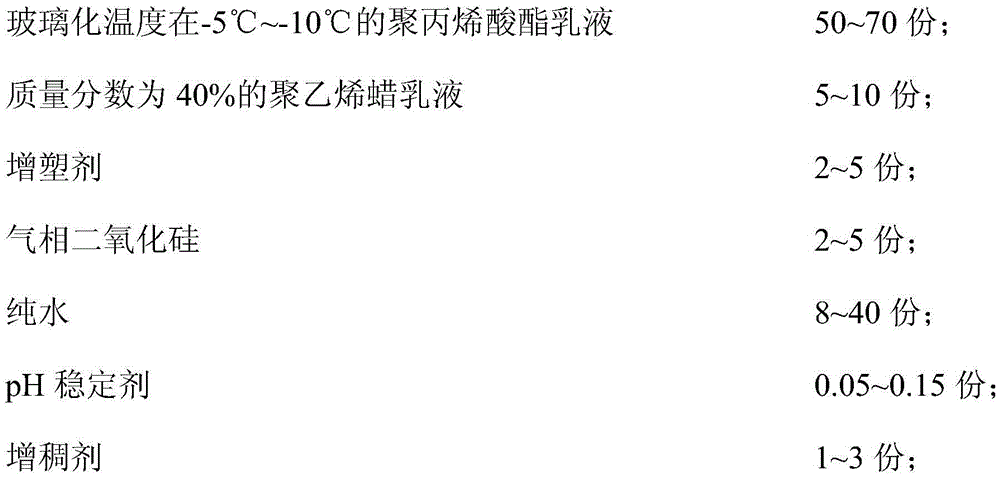

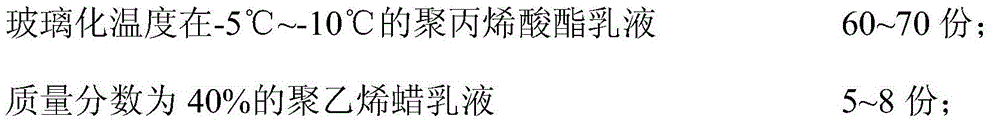

[0070] The preparation method of the disposable feel pulp for artificial flowers comprises the following steps:

[0071] (1) Preparation of component A: While stirring, add polyethylene wax emulsion with a mass fraction of 40%, plasticizer, fumed silica and pure water in sequence at a glass transition temperature of -5°C to -10°C In the polyacrylate emulsion, continue to stir and disperse at a speed of 800-1000r / min for 10-20min; according to the pH value of the slurry, add a pH stabilizer to adjust the pH to 7; according to the viscosity requirement, use a thickener to thicken the slurry Thick, and increase the rotation speed to 2000-2500r / min to disperse for 10-20min; use 100-150 mesh gauze to filter to obtain A component slurry;

[0072] (2) Add component B to component A slurry obtained in step (1) before using the hand feel slurry, stir evenly, and store the slurry at 30°C to obtain a disposable hand feel slurry for artificial flowers.

[0073] The following examples all...

Embodiment 1

[0075] A component:

[0076] raw material name

Proportion / part

Remark

JN-230

70

Tg: -10℃, solid content: 49 parts

HA-40

8

3

HDK N20

4

AMP-95

0.05

pure water

13.95

MC35

1

[0077] B component:

[0078] raw material name

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com