Dielectric adjustable magnesium oxide and barium zirconium titanate composite ceramic

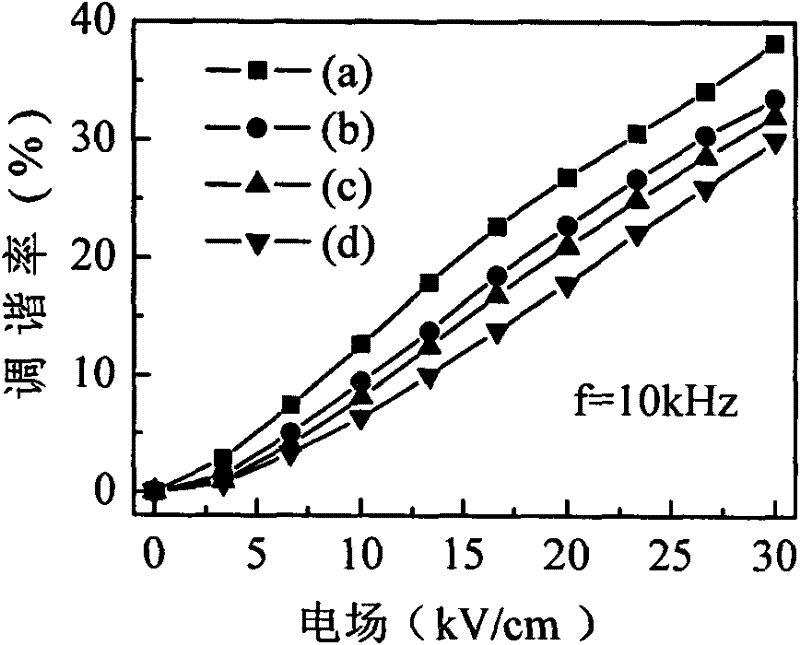

A technology of compounding barium zirconate titanate and magnesium oxide, which is applied in the field of functional ceramics, can solve the problems of large dielectric constant and dielectric loss, large dielectric constant and dielectric loss, and difficulty in meeting the requirements of use, and achieve a reduction in dielectric constant , high tuning rate, low dielectric loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

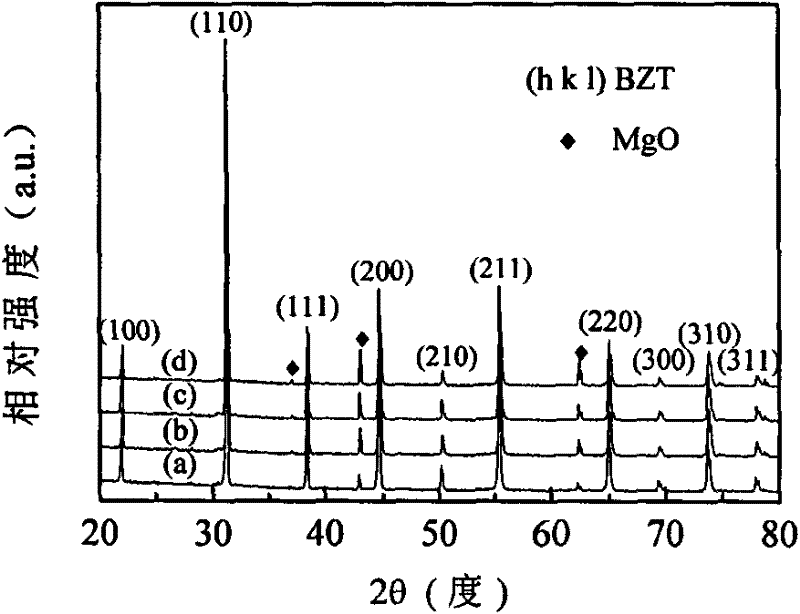

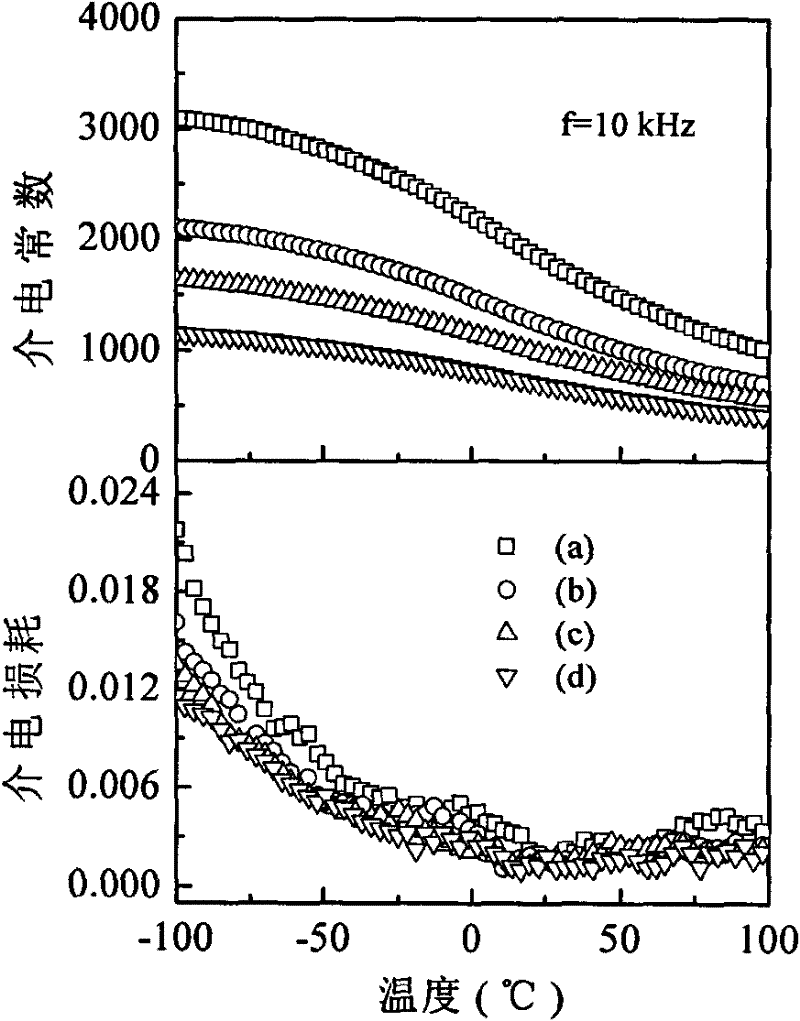

[0019] Embodiment 1, weighing 16.173g BaCO 3 , 4.909g TiO 2 , 8.796g Zr(NO 3 ) 4 ·5H 2 0, put the weighed material into the ball mill tank, press the zirconia ball: material: alcohol is 3: 1: 1 ratio mixing ball mill, the ball milling time is 4 hours; the briquetting after the mixed material is dried, Pre-calcined at 1100°C for 4 hours, took out the calcined material and ground it to obtain 20g of BZT pre-calcined powder, then weighed 9g of BZT powder and 0.9g of MgO, put them into a ball mill jar, ball milled for another 8 hours, and baked After drying, sieve; pre-press the sieved powder into a disc with a diameter of 12 mm and a thickness of 1 mm, and then finally shape it under an isostatic pressure of 200 MPa; keep the formed disc at 1250 ° C for 6 hours; after sintering into porcelain, it is ground and polished, then coated with silver paste, and kept at 550°C for 30 minutes to burn the silver electrodes. The ceramic structure was tested with a fully automatic X-ray ...

Embodiment 2

[0020] Embodiment 2, weighing 16.173g BaCO 3 , 4.909g TiO 2 , 8.796g Zr(NO 3 ) 4 ·5H 2 0, put the weighed material into the ball mill tank, press the zirconia ball: material: alcohol is 3: 1: 1 ratio mixing ball mill, the ball milling time is 5 hours; the briquetting after the mixed material is dried, Pre-calcined at 1150°C for 3 hours, took out the calcined material and ground it to obtain 20g of BZT pre-calcined powder, then weighed 8g of BZT powder and 1.6g of MgO, put them into a ball mill jar, ball milled for another 10 hours, and baked After drying, sieve; pre-press the sieved powder into a disc with a diameter of 12 mm and a thickness of 1 mm, and then finally shape it under an isostatic pressure of 200 MPa; keep the formed disc at 1300 ° C for 4 hours; after sintering into porcelain, it is ground and polished, then coated with silver paste, and kept at 550°C for 30 minutes to burn the silver electrode. The ceramic structure was tested with a fully automatic X-ray ...

Embodiment 3

[0021] Embodiment 3, weighing 16.173g BaCO 3 , 4.909g TiO 2 , 8.796g Zr(NO 3 ) 4 ·5H 2 0, put the weighed material into the ball mill tank, press the zirconia ball: material: alcohol is 3: 1: 1 ratio mixing ball mill, the ball milling time is 6 hours; the briquetting after the mixed material is dried, Pre-calcin at 1200°C for 2 hours, take out the calcined material and grind to obtain 20g of BZT pre-calcined powder, then weigh 7g of BZT powder and 2.1g of MgO, put them into a ball mill jar, ball mill for another 11 hours, bake After drying, sieve; pre-press the sieved powder into a disc with a diameter of 12 mm and a thickness of 1 mm, and then finally shape it under an isostatic pressure of 200 MPa; keep the formed disc at 1350 ° C for 2 hours; after sintering into porcelain, it is ground and polished, then coated with silver paste, and kept at 550°C for 30 minutes to burn the silver electrode. The ceramic structure was tested with a fully automatic X-ray diffractometer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com