Continuous heat transfer sulfur dioxide conversion process

A technology of sulfur dioxide and heat removal, applied in inorganic chemistry, sulfur compounds, chemical instruments and methods, etc., can solve problems such as difficulty in removing heat, and achieve the effect of ensuring no corrosion, simple control, and solving the bottleneck of temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

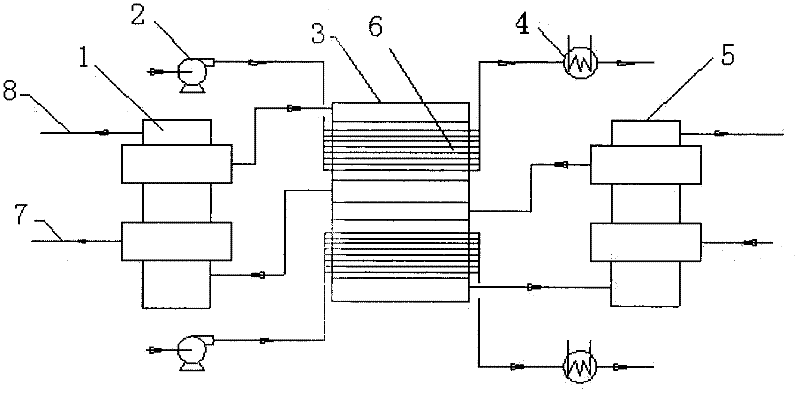

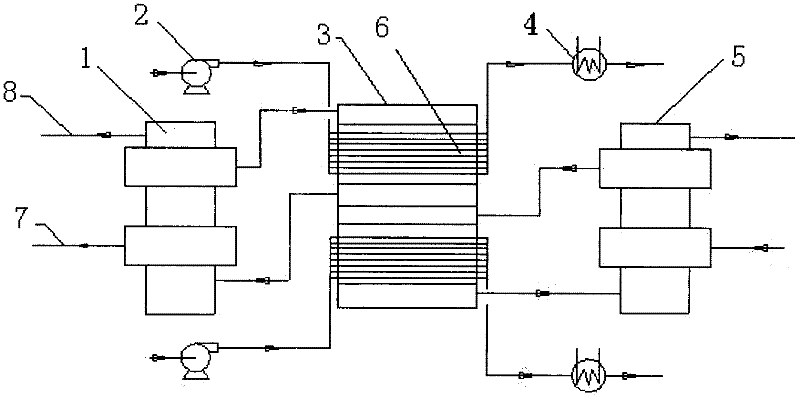

[0015] Continuous heat removal sulfur dioxide conversion process, the steps are:

[0016] 1) The flue gas from the sulfur dioxide blower enters the shell side of the primary conversion heat exchanger 1 through the pipeline 7 before conversion, and after being heated to the coal contact ignition temperature (420±10°C), enters the first reaction layer of the converter 3;

[0017] 2) The flue gas in step 1) undergoes oxidation reaction in the first-stage reaction layer of the converter 3, and the coal-contacting layer of the first-stage reaction layer is provided with an internal heat pipe 6, and cold air or cold water or low-pressure steam is passed into the internal heat pipe 6 , the heat generated by the oxidation reaction is removed by the cold air or cold water or low-pressure steam in the internal heat pipe 6, and the temperature of the converter 3 is controlled to be 520±10° C. by adjusting the flow rate of the cooling fan 2;

[0018] 3) Contains a lot of SO 3 The flue ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com