Cable taking-up/paying-off control system of hydrographic winch

A control system and winch technology, which is applied to ships, cargo handling equipment, passenger processing equipment, etc., can solve the problems that the data cannot truthfully reflect the real situation, the underwater position of the load cannot be accurately measured, and the speed of lowering the load is lacking. It is convenient and fast Complete work, easy installation and placement, simple and clear wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

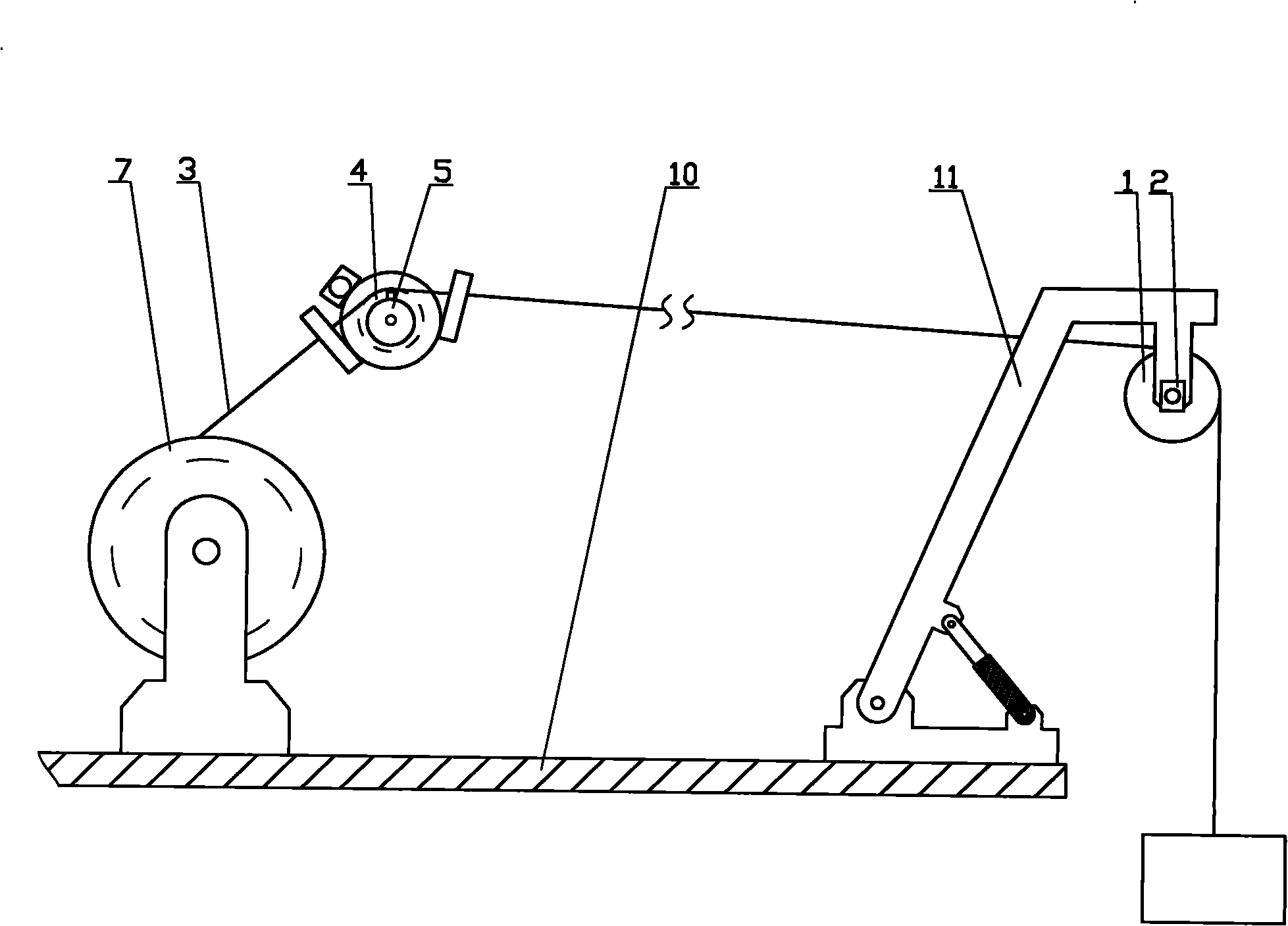

[0045]The present invention will be further described below in conjunction with accompanying drawing.

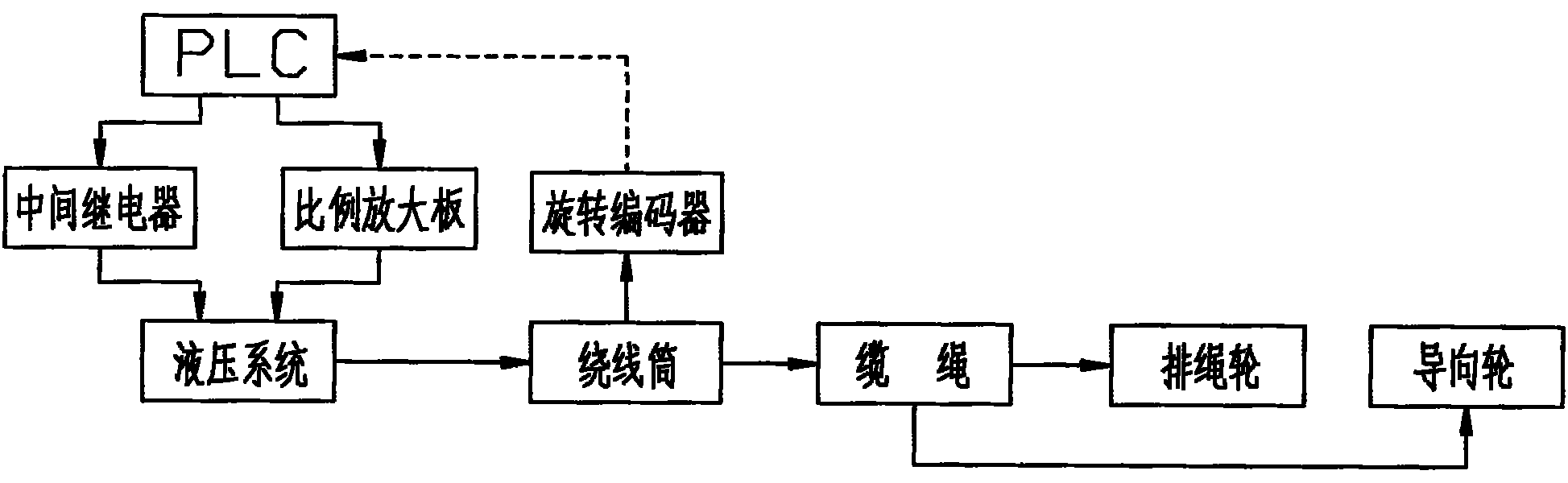

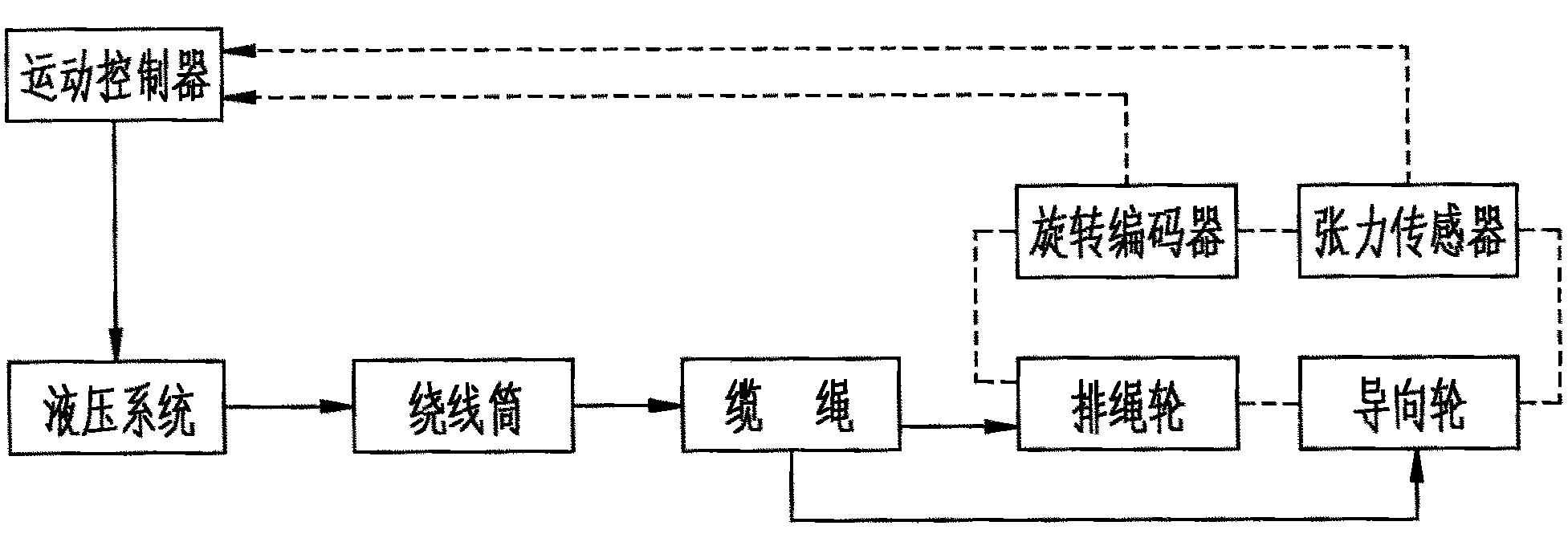

[0046] figure 1 Among them, the existing hydrological winch's receiving / releasing cable control system mainly includes PLC, intermediate relay, proportional amplification board, hydraulic system, bobbin, cable, and rotary encoder is installed on the bobbin, and the signal of rotary encoder is connected to PLC, PLC The hydraulic system is controlled by the intermediate relay and the proportional amplifier board to drive the bobbin to rotate to retract and unwind the cable. Due to the lack of accurate monitoring of the length, speed and tension of the cable, the traditional hydrological winch cannot accurately locate the position and status of the underwater equipment; at the same time, because the PLC is the control core, the current signal of its control loop is far smaller than that of the hydraulic system. The working current signal quantity, so the signal can only be amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com