Silicone-free submersed nozzle and manufacturing method thereof

A manufacturing method and immersion technology, which is applied in the direction of manufacturing tools, casting equipment, casting molten material containers, etc., can solve the problems of exacerbating the incidence of accidents, affecting continuous casting continuous operation, and affecting the quality of continuous casting slabs, so as to ensure smoothness , low thermal expansion coefficient, large application potential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment.

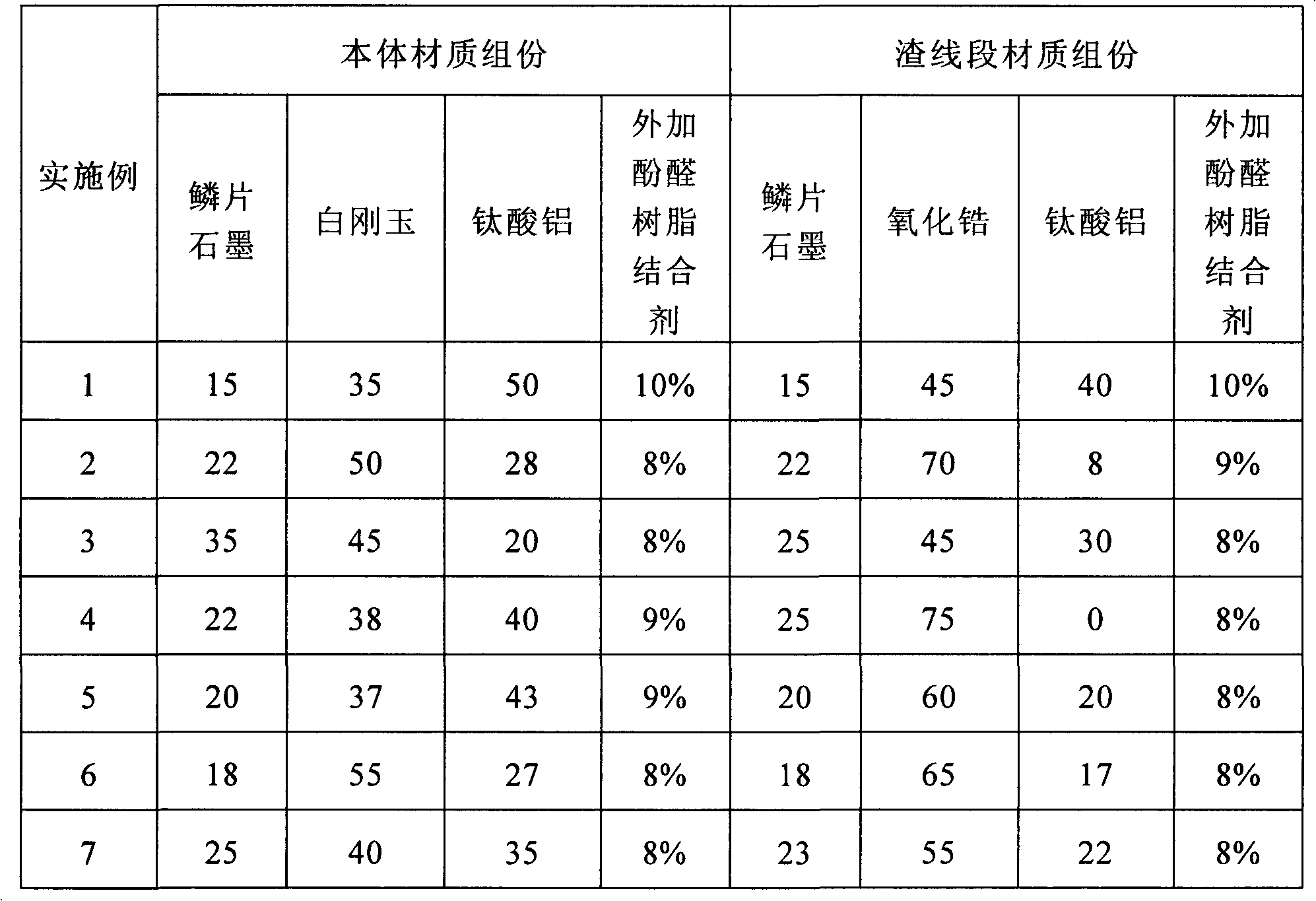

[0026] Refer to Table 1 for the composition of the silicon-free submerged nozzle embodiment of the present invention.

[0027] The preparation method of the silicon-free submerged nozzle of the present invention comprises the following steps: uniformly mixing the material of the body and the material of the slag line respectively, adding 10% of the above-mentioned components to the phenolic resin binder, and using a granulator to mix the raw materials Granulation, the granulated material is dried on the drying bed to make it meet the molding requirements, the main material granulated material and the slag line material granulated material are respectively added to the mold, and the static pressure machine is used to press and form under a pressure of 80-150 MPa; forming The product is fired in a shuttle kiln at 1200-1300°C in a reducing atmosphere or an oxygen-free environment. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com