Fabrication method for crystalline silicon solar cell

A solar cell and manufacturing method technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as cost increase, waste of phosphorus source, complicated process flow, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

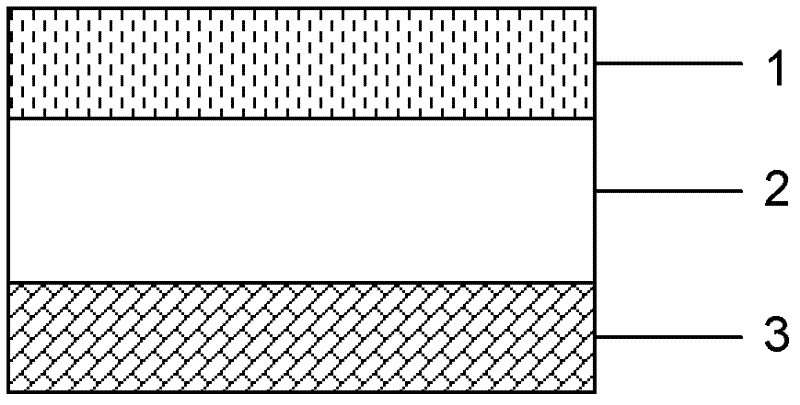

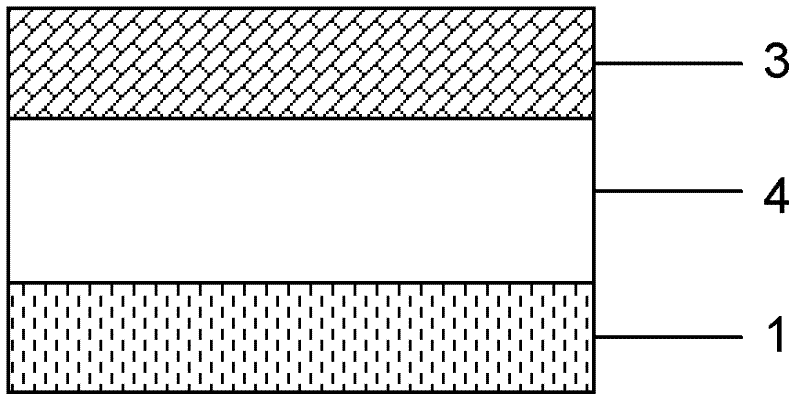

[0044] In this embodiment, the p-type crystalline silicon substrate 2 adopts a p-type single crystal silicon wafer, and the boron-containing silicon nitride film or boron nitride film 3 adopts a boron-containing silicon nitride film, which is obtained by the manufacturing method of the present invention A cutaway view of a crystalline silicon solar cell image 3 As shown, the specific production process is as follows:

[0045] Step 1: cleaning the p-type crystalline silicon substrate 2 with a conventional cleaning method, and using an alkaline solution to make a suede surface;

[0046] Step 2: Put the p-type crystalline silicon substrate 2 in the PECVD reaction chamber, pass through silane, ammonia gas and a small amount of phosphine, and deposit phosphorus on the front surface of the p-type crystalline silicon substrate 2 at a reaction temperature of 300°C silicon nitride film 1, the thickness of the phosphorus-containing silicon nitride film 1 is 70nm;

[0047] Step 3: Tak...

Embodiment 2

[0053] In this embodiment, the p-type crystalline silicon substrate 2 adopts a p-type single crystal silicon wafer, the boron-containing silicon nitride film or boron nitride film 3 adopts a boron nitride film, and the crystalline silicon solar energy obtained by the manufacturing method of the present invention The three-dimensional cutaway view of the battery is similar to image 3 As shown, the specific production process is as follows:

[0054] The concrete manufacturing method of crystalline silicon solar cell comprises the following steps:

[0055] Step 1: cleaning the p-type crystalline silicon substrate 2 with a conventional cleaning method, and using an alkaline solution to make a suede surface;

[0056] Step 2: Put the p-type crystalline silicon substrate 2 in the PECVD reaction chamber, pass through silane, ammonia gas and a small amount of phosphine, and deposit phosphorus on the front surface of the p-type crystalline silicon substrate 2 at a reaction temperature...

Embodiment 3

[0063] In this embodiment, the p-type crystalline silicon substrate 2 adopts a p-type single crystal silicon wafer, the boron-containing silicon nitride film or boron nitride film 3 adopts a boron nitride film, and the crystalline silicon solar energy obtained by the manufacturing method of the present invention The three-dimensional cutaway view of the battery is shown in image 3 As shown, the specific production process is as follows:

[0064] Step 1: cleaning the p-type crystalline silicon substrate 2 with a conventional cleaning method, and using an alkaline solution to make a suede surface;

[0065] Step 2: Put the p-type crystalline silicon substrate 2 in the PECVD reaction chamber, pass through silane, ammonia gas and a small amount of phosphine, and deposit phosphorus on the front surface of the p-type crystalline silicon substrate 2 at a reaction temperature of 350°C silicon nitride film 1, the thickness of the phosphorus-containing silicon nitride film 1 is 70nm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com