Surface modifying method for improving antibacterial property and biological activity of medicinal titanium

A bioactive and surface modification technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of poor antibacterial and biological activity, and achieve the effect of no toxic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

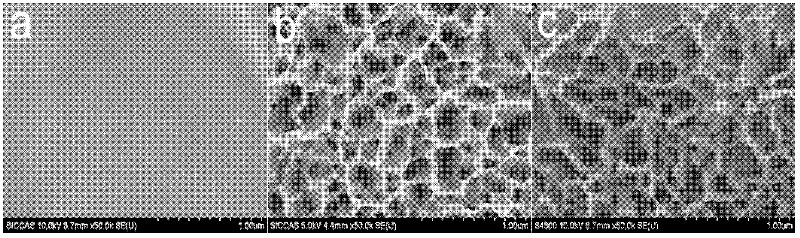

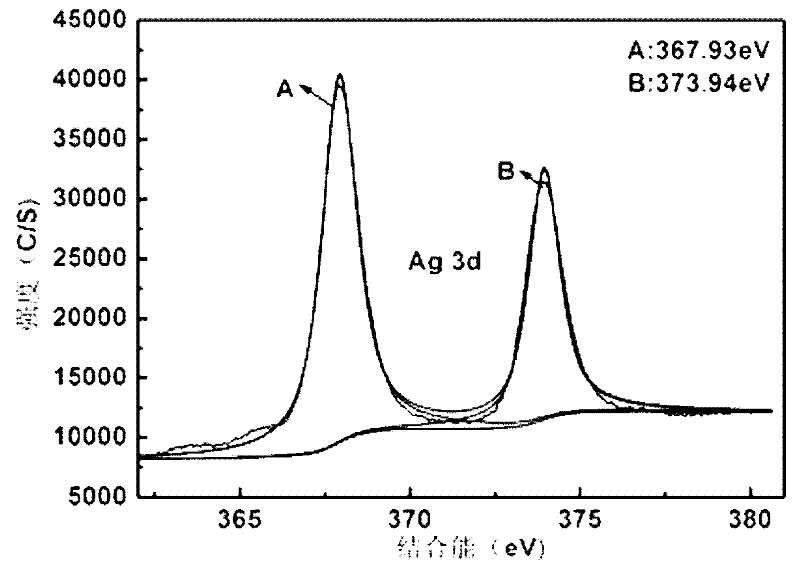

Image

Examples

Embodiment 1

[0032] A pure titanium metal sheet of 10mm×10mm×1mm was treated with 5wt% oxalic acid at 100°C for 2 hours, cleaned ultrasonically with deionized water, and dried naturally.

[0033] Put the pure titanium metal sheet pretreated by oxalic acid into the autoclave, pour hydrogen peroxide with a mass fraction of 30% into the autoclave, add 5ml of hydrogen peroxide to each pure titanium metal sheet, and treat at 80°C 6h.

[0034] The samples after hydrothermal treatment for 6 h were taken out and dried naturally. Using plasma immersion ion implantation technology, silver is implanted into the titanium metal substrate after hydrothermal treatment. The specific process parameters are shown in Table 1:

[0035] Table 1 Silver ion implantation parameters

[0036] Injection voltage (kV)

15

Pulse width (μs)

450

Injection time (h)

0.5h

Background vacuum (Pa)

3.6×10 -3

Negative high voltage current (mA)

2.2

Frequency (Hz) ...

Embodiment 2

[0040] A pure titanium metal sheet of 10mm×10mm×1mm was treated with 5wt% oxalic acid at 100°C for 2 hours, cleaned ultrasonically with deionized water, and dried naturally.

[0041] Put the pure titanium metal sheet pretreated by oxalic acid into the autoclave, pour hydrogen peroxide with a mass fraction of 30% into the autoclave, add 5ml of hydrogen peroxide to each pure titanium metal sheet, and treat at 80°C 24h.

[0042] The samples after hydrothermal treatment for 24 h were taken out and dried naturally. Using plasma immersion ion implantation technology, silver is implanted into the titanium metal substrate after hydrothermal treatment. The specific process parameters are shown in Table 2:

[0043] Table 2 Silver ion implantation parameters

[0044] Injection voltage (kV)

15

Pulse width (μs)

450

Injection time (h)

1h

Background vacuum (Pa)

3.6×10 -3

Negative high voltage current (mA)

2.2

Frequency (Hz) ...

Embodiment 3

[0048] A pure titanium metal sheet of 10mm×10mm×1mm was treated with 5wt% oxalic acid at 100°C for 2 hours, cleaned ultrasonically with deionized water, and dried naturally.

[0049] Put the pure titanium metal sheet pretreated by oxalic acid into the autoclave, pour hydrogen peroxide with a mass fraction of 30% into the autoclave, add 5ml of hydrogen peroxide to each pure titanium metal sheet, and treat at 80°C 72h.

[0050] Take out the sample after hydrothermal treatment for 72h, and let it dry naturally. Using plasma immersion ion implantation technology, silver is implanted into the titanium metal substrate after hydrothermal treatment. The specific process parameters are shown in Table 3:

[0051] Table 3 Silver ion implantation parameters

[0052] Injection voltage (kV)

15

Pulse width (μs)

450

Injection time (h)

1h

Background vacuum (Pa)

3.6×10 -3

Negative high voltage current (mA)

2.2

Frequency (Hz)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com