Micro-foam agent for oil field oil gas well cementation and preparation method thereof

A micro-foaming agent and well cementing technology, which is applied in the field of oil well cementing, can solve the problems of reduced compressive strength of cement slurry solidified body, difficulty of foamed cement slurry, complicated construction process, etc., so as to improve saponification effect and improve high temperature resistance performance. , the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A microfoam agent for oil and gas well cementing in an oil field, which is composed of a microfoam semi-finished product and sepiolite clay in a weight ratio of 1:30;

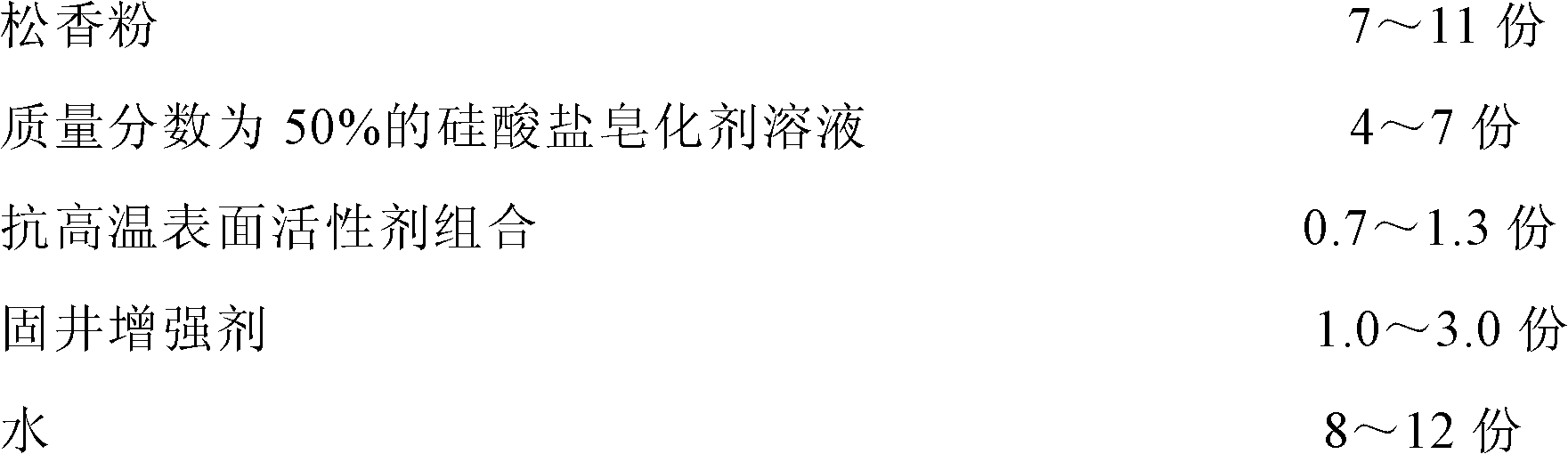

[0037] Described microfoam semi-finished product is made up of the component of following parts by weight:

[0038]

[0039] The preparation method of microfoam agent for oil and gas well cementing in this oil field comprises the steps:

[0040] In the first step, inject 10 parts by weight of water into the liquid mixing tank with agitator, stir and heat to 80-90 °C, and add 5 parts by weight of potassium silicate solution with a mass fraction of 50% to the liquid mixing tank Medium, rotating speed 100-400 rpm, stirring for 0.5h;

[0041] In the second step, at a temperature of 90°C and a rotating speed of 100-400 rpm, add 8 parts by weight of rosin powder to the stirred solution in the first step, stir for 2.5 hours, and carry out saponification until the water content is 20 up to -27%;

[0042] I...

Embodiment 2

[0045] A microfoam agent for oil and gas well cementing in an oil field, which is composed of a microfoam semi-finished product and sepiolite clay in a weight ratio of 1:30;

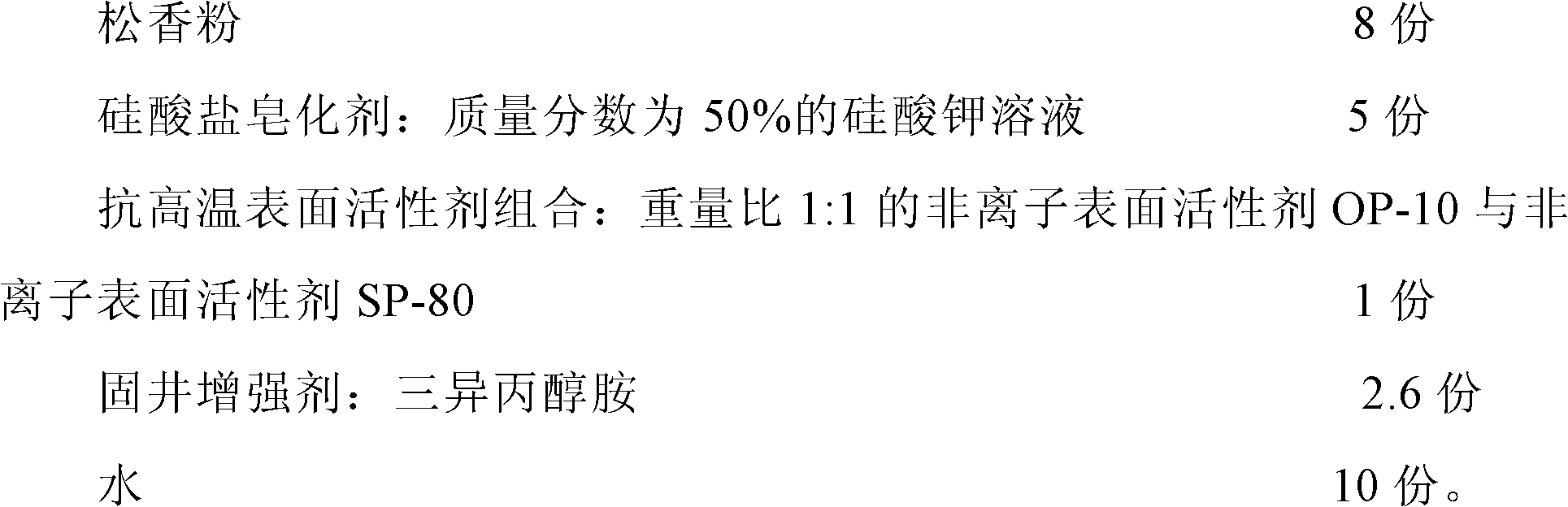

[0046] Described microfoam semi-finished product is made up of the component of following parts by weight:

[0047]

[0048] The preparation method of microfoam agent for oil and gas well cementing in this oil field comprises the steps:

[0049] In the first step, inject 10 parts by weight of water into the liquid mixing tank with agitator, stir and heat to 80-90°C, and add 5 parts by weight of sodium silicate solution with a mass fraction of 50% into the liquid mixing tank Medium, rotating speed 100-400 rpm, stirring for 0.5h;

[0050] In the second step, at a temperature of 90°C and a rotating speed of 100-400 rpm, add 8 parts by weight of rosin powder to the stirred solution in the first step, stir for 2.5 hours, and carry out saponification until the water content is 20 up to -27%;

[0051] In ...

Embodiment 3

[0054] A microfoam agent for oil and gas well cementing in an oil field, which is composed of microfoam semi-finished products and sepiolite clay with a weight ratio of 1:35;

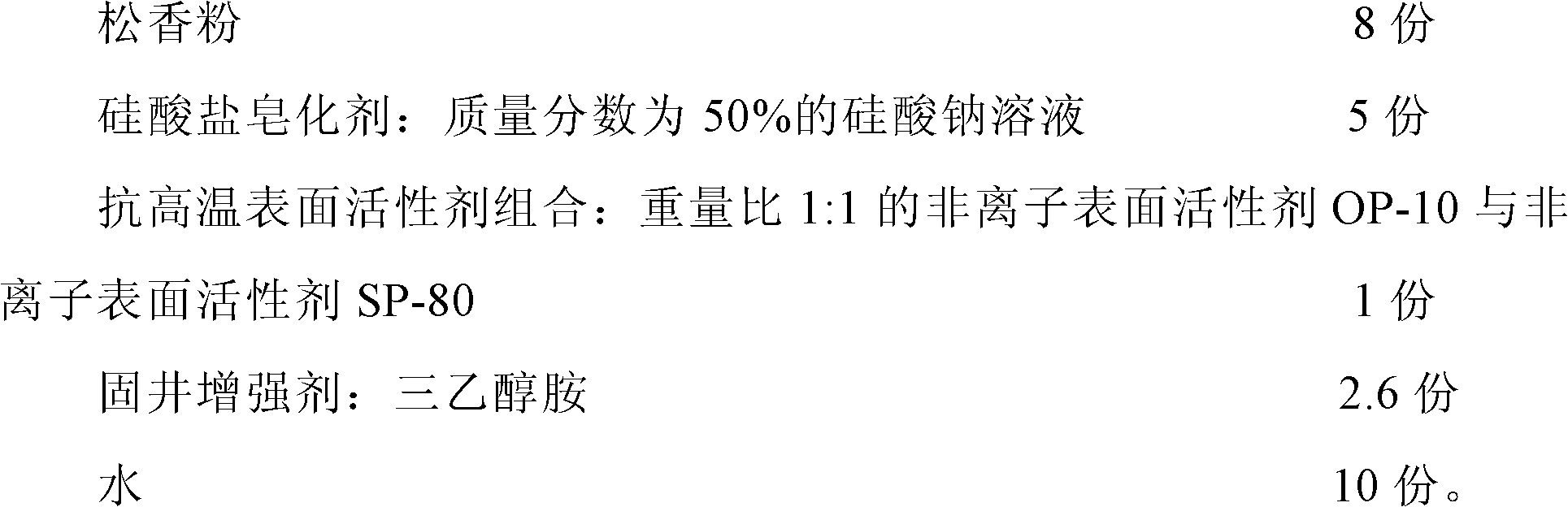

[0055] Described microfoam semi-finished product is made up of the component of following parts by weight:

[0056]

[0057] The preparation method of microfoam agent for oil and gas well cementing in this oil field comprises the steps:

[0058] In the first step, inject 10 parts by weight of water into the liquid mixing tank with agitator, stir and heat to 80-90°C, and add 5 parts by weight of sodium silicate solution with a mass fraction of 50% into the liquid mixing tank Medium, rotating speed 100-400 rpm, stirring for 0.5h;

[0059] In the second step, at a temperature of 90°C and a rotating speed of 100-400 rpm, add 8 parts by weight of rosin powder to the stirred solution in the first step, stir for 2.5 hours, and carry out saponification until the water content is 20 up to -27%;

[0060] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com