Amide-type aid and preparation method thereof

A technology of amide and additives, which is applied in the field of composite solid propellant manufacturing, can solve the problems of affecting the mechanical properties and aging properties of the formula, accelerating the wetting speed of the adhesive, and affecting the mechanical properties of the propellant, etc., to achieve leveling Good properties, improved wetting state, reduced yield value and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Add 85% linoleic acid dimer acid into the reaction kettle, feed nitrogen, when the temperature in the kettle rises to 95°C, add triethylenetetramine with a content greater than 99.5%, triethylenetetramine and The molar ratio of linoleic acid dimer acid is 2.5:1, continue to heat up to 155°C, start the acylation reaction in the kettle, keep the temperature in the kettle at 160°C~180°C for 2 hours, continue to heat up to 238°C, maintain React at this temperature for 1.5 hours. When no water is produced, the reaction is complete. Start to lower the temperature, and replace the vacuum distillation device to evaporate excess triethylenetetramine to obtain amide additives.

Embodiment 2

[0012] Example 2: Add linoleic acid dimer acid with a content of 90% into the reaction kettle, feed nitrogen, and when the temperature in the kettle rises to 100°C, add triethylenetetramine with a content greater than 99.5%, triethylenetetramine The molar ratio with linoleic acid dimer acid is 2.5:1, continue to heat up to 157°C, start the acylation reaction in the kettle, keep the temperature in the kettle at 160°C~180°C for 2 hours, continue to heat up to 238°C, Maintain this temperature for 1.5 hours. When no water is produced in the reaction, the reaction is complete, start to lower the temperature, and replace the vacuum distillation device to evaporate excess triethylenetetramine to obtain amide additives.

Embodiment 3

[0013] Example 3: Add linoleic acid dimer acid with a content of 92% into the reaction kettle, feed nitrogen, and when the temperature in the kettle rises to 105°C, add triethylenetetramine with a content greater than 99.5%, triethylenetetramine The molar ratio with linoleic acid dimer acid is 2.5:1, continue to heat up to 160°C, start the acylation reaction in the kettle, keep the temperature in the kettle at 160°C~180°C for 2 hours, continue to heat up to 238°C, Maintain this temperature for 1.5 hours. When no water is produced in the reaction, the reaction is complete, start to lower the temperature, and replace the vacuum distillation device to evaporate excess triethylenetetramine to obtain amide additives.

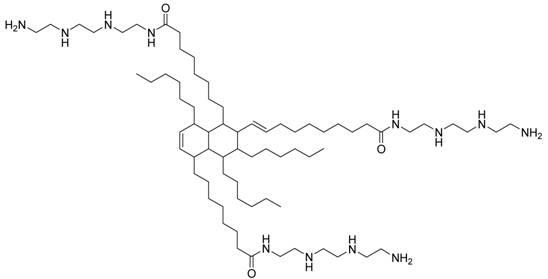

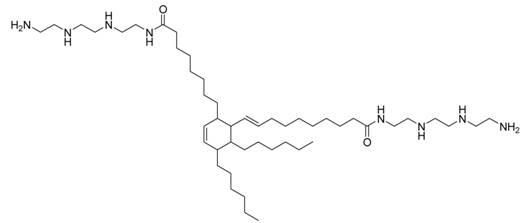

[0014] The obtained amide additives contain substance A: N-(2-(2-(2-aminoethylamino)ethylamino)ethyl)-10-(2-(8-(2-(2-(2-amino) Ethylamino)ethylamino)ethylamino)-8-oxooctyl)-5,6-dihexyl-3-cyclohexenyl)9-decenamide; Substance B: 10-2-(1,5- Bis(8-(2-(2-(2-aminoethylami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com