Preparation method for cyanoethyl graft amide

A method of determination, the technology of dimethyl sulfoxide, applied in the field of cyanoethyl grafted amide and its preparation, can solve the problems of too fast increase of the viscosity of the syrup, high reactivity, and less dosage, and achieve the flow flow of the syrup Good flatness, stable reaction process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

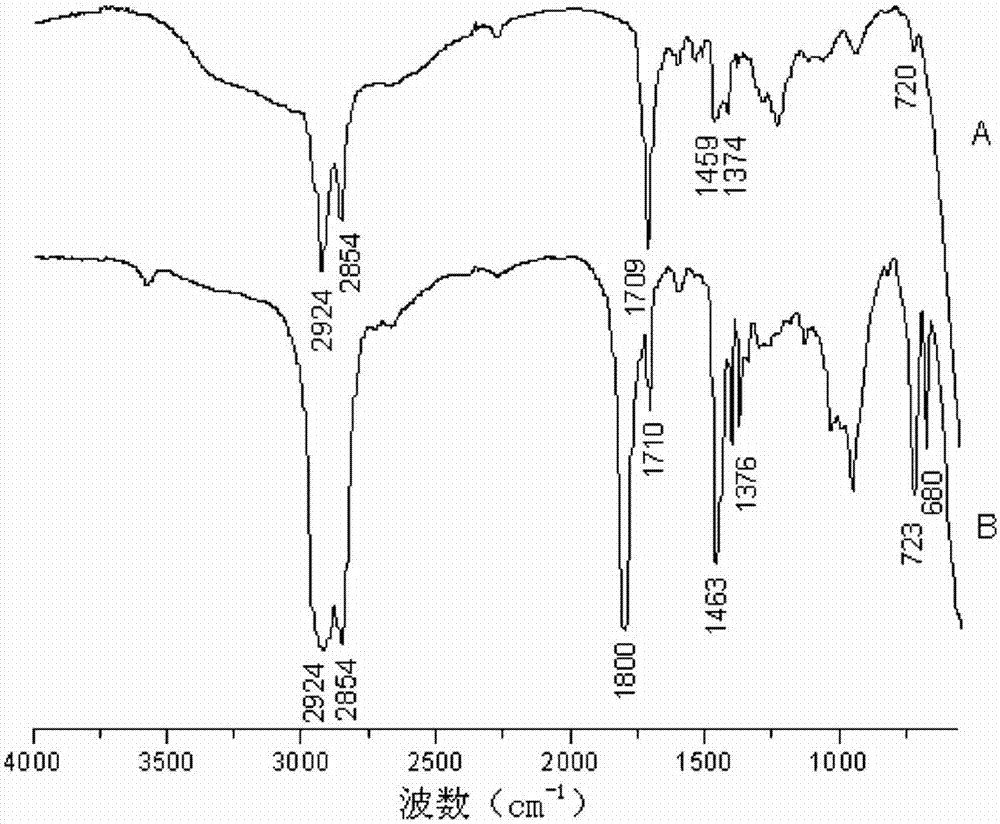

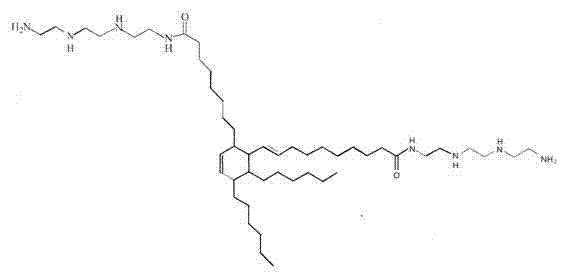

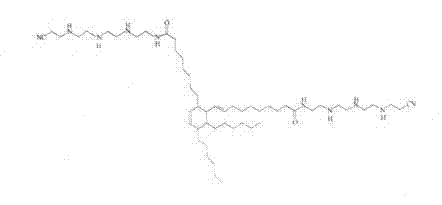

Image

Examples

Embodiment 1

[0018] Dissolve the amide in 4.5 times the volume of dimethyl sulfoxide solvent, add dropwise acrylonitrile with a molar ratio of 2.8 times under mechanical stirring, and use an ice-water bath to cool the dropwise addition of acrylonitrile so that the liquid phase temperature is maintained at 30 ℃. Under the condition of reflux and stirring, react at 78°C for 6h; stop the reaction, evaporate excess acrylonitrile and inert solvent to obtain cyanoethyl grafted amide.

Embodiment 2

[0020] The amide was dissolved in 4.5 times the volume of dimethyl sulfoxide and acetone 1:1 mixed solution solvent, and under mechanical stirring, 2.5 times the molar ratio of acrylonitrile was added dropwise. The liquidus temperature was maintained at 30°C. Under the condition of reflux and stirring, react at 50°C for 12h; stop the reaction, evaporate excess acrylonitrile and inert solvent to obtain cyanoethyl grafted amide.

Embodiment 3

[0022] Dissolve the amide in 3 times the volume of dimethyl sulfoxide solution solvent, add dropwise acrylonitrile with a molar ratio of 2.2 times under mechanical stirring, and use an ice-water bath to cool the dropwise addition of acrylonitrile so that the liquid phase temperature is maintained at 27°C. React at 100°C for 3 hours under reflux and stirring; stop the reaction, distill off excess acrylonitrile and inert solvent to obtain cyanoethyl grafted amide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com