Polyolefin battery diaphragm and preparation method for the same

A battery membrane and polyolefin technology, which is applied to fuel cells, battery pack components, fuel cell components, etc., can solve the problems of complex equipment investment, low puncture strength, and difficult operation, and achieve simple stretching operation. , uniform mechanical strength, good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

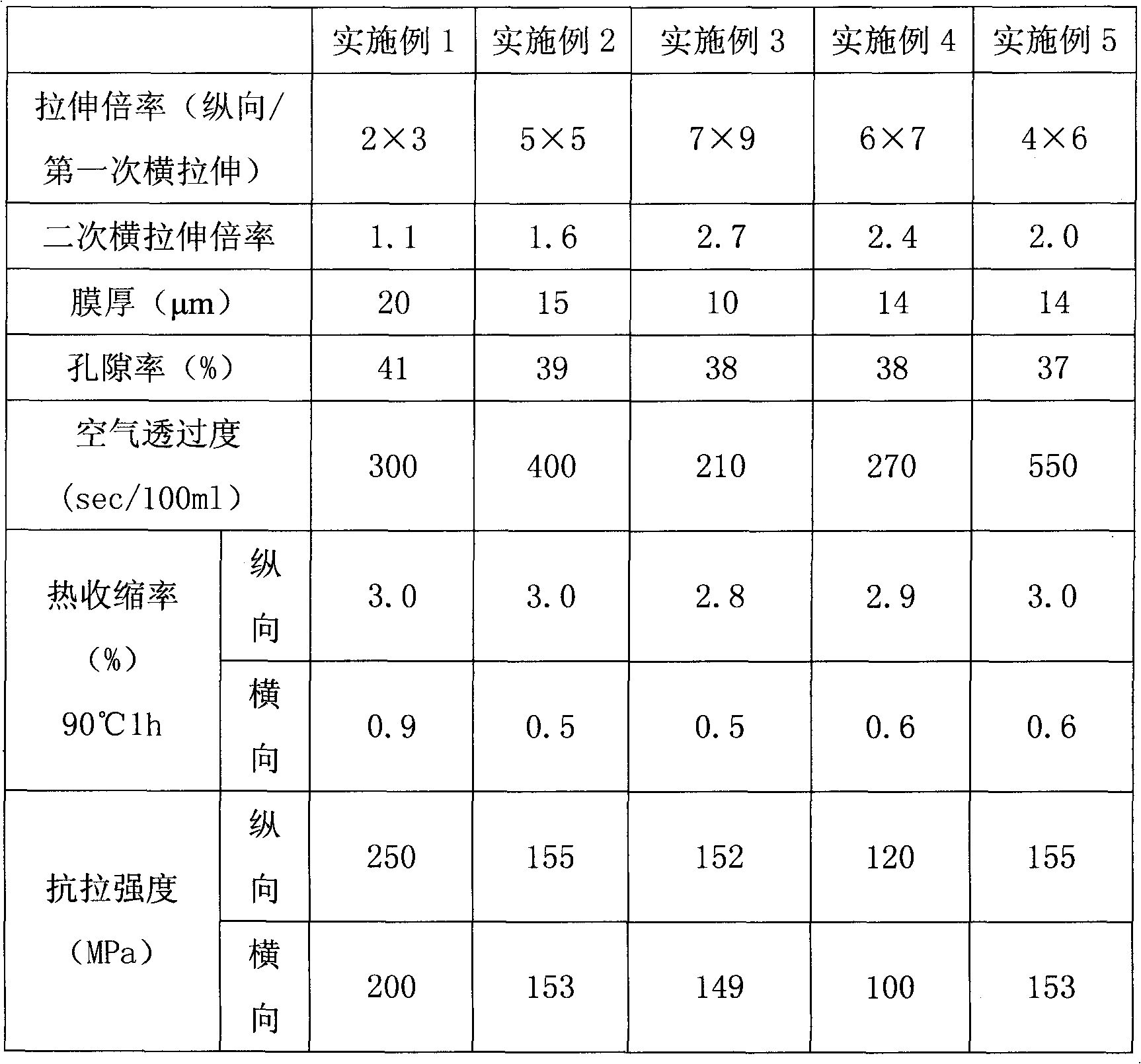

Examples

preparation example Construction

[0029] A preparation method of a polyolefin battery diaphragm, the preparation method consists of the following steps:

[0030] 1) Melt polyolefin resin, additives and solvents at a temperature of 150-280°C to form a uniform melt, wherein the weight percentage of each component is:

[0031] Polyolefin resin 15-40%,

[0032] Additive 1~10%,

[0033] The balance is solvent;

[0034] 2) extruding the molten liquid obtained in the step 1 through a die head at a temperature of 150-280° C., cooling it on a cooling roll and casting it into a thick sheet, and the cooling temperature is -5-30° C.;

[0035] 3) The slab obtained in step 2 is first stretched longitudinally, the stretching temperature is 50°C-110°C, and the longitudinal stretching ratio is 2-7 times; then the first transverse stretching is carried out, and the stretching temperature is 90°C ~150℃, the stretching ratio of the first transverse stretching is 3~9 times;

[0036] 4) extracting and removing the solvent from ...

Embodiment 1

[0046] 18% (accounting for the percentage of total feeding weight) of high-density polyethylene (HDPE, viscosity-average molecular weight 2.5 * 10 5 , melting point is 130°C), 1% (percentage of total feed weight) of antioxidant 1010 and 1% (percentage of total feed weight) of antistatic agent 600. Mix dryly in the mixer, join in twin-screw extruder (diameter 58mm, L / D=52, strong mixing type), then use metering pump, add 80% (accounting for total feeding weight) percentage) of liquid paraffin (dynamic viscosity 90cst / 40°C), melting and mixing the resin at 150°C and 156 rpm. The mixed resin solution was extruded through a T-die, and the cast sheet was cooled on a cooling roll with a surface temperature of 20° C. to obtain a thick sheet with a thickness of 0.13 mm.

[0047] The slab is stretched longitudinally and transversely in sequence, wherein the stretching ratio is vertical×horizontal=2×3, the longitudinal stretching temperature is 100°C, and the transverse stretching temp...

Embodiment 2

[0049] 15% (accounting for the percentage of total feeding weight) of high-density polyethylene (HDPE, viscosity-average molecular weight 2.5 * 10 5 , melting point is 130 ℃), 5% (accounting for the percentage of total feeding weight) poly-1-butene, 5% (accounting for the percentage of total feeding weight) of ultra-high molecular weight polyethylene (UHMWPE, viscosity-average molecular weight 1 × 10 6 , melting point 134), 3% (percentage of total feed weight) of antioxidant 1076 and 3% (percentage of total feed weight) of antistatic agent 600. Mix dryly in the mixer, join in twin-screw extruder (58mm in diameter, L / D=52, strong mixing type), then use metering pump, add 69% (accounting for total feeding weight) percentage) of liquid paraffin (dynamic viscosity 90cst / 40°C), melting and mixing the resin at 170°C and 156 rpm. The mixed resin solution was extruded through a T-die, and the cast sheet was cooled on a cooling roll with a surface temperature of 20° C. to obtain a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal stretch temperature | aaaaa | aaaaa |

| Transverse stretch temperature | aaaaa | aaaaa |

| Longitudinal stretch temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com