In-situ on-line detection device for metallurgy liquid metal component

A liquid metal and detection device technology, applied in the direction of material excitation analysis, etc., can solve problems such as undetectable, achieve the effects of reducing energy consumption, reducing production costs, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

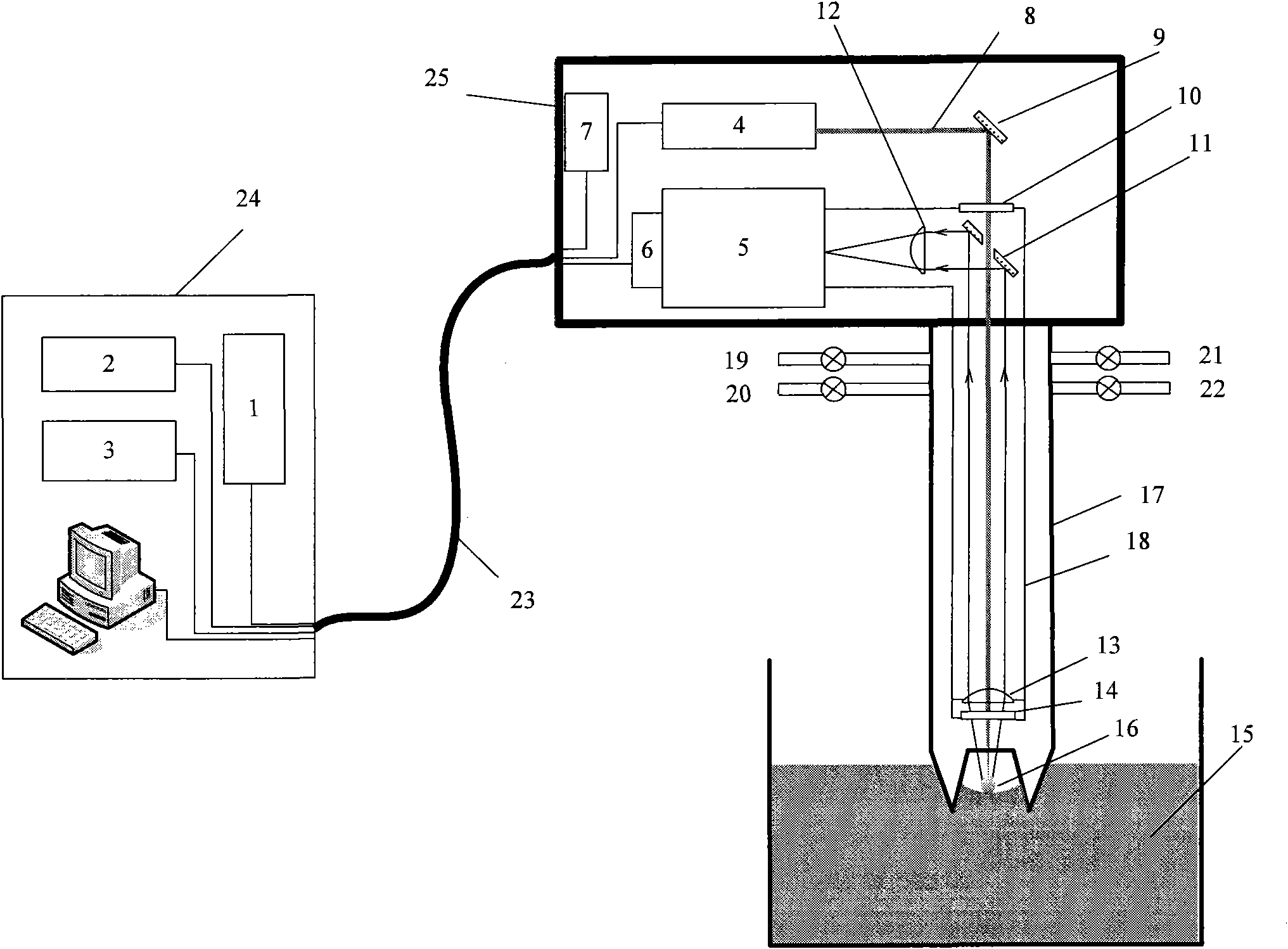

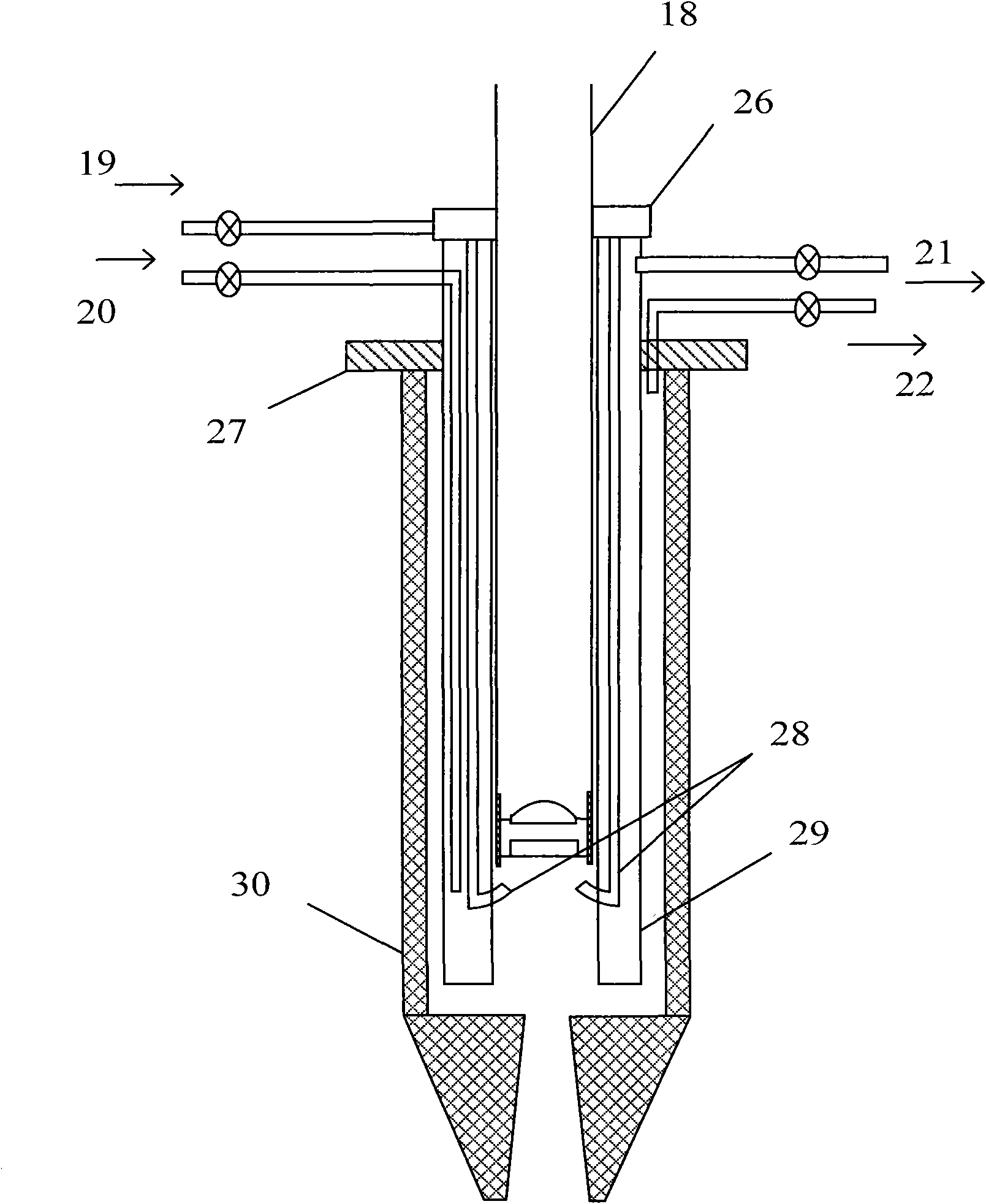

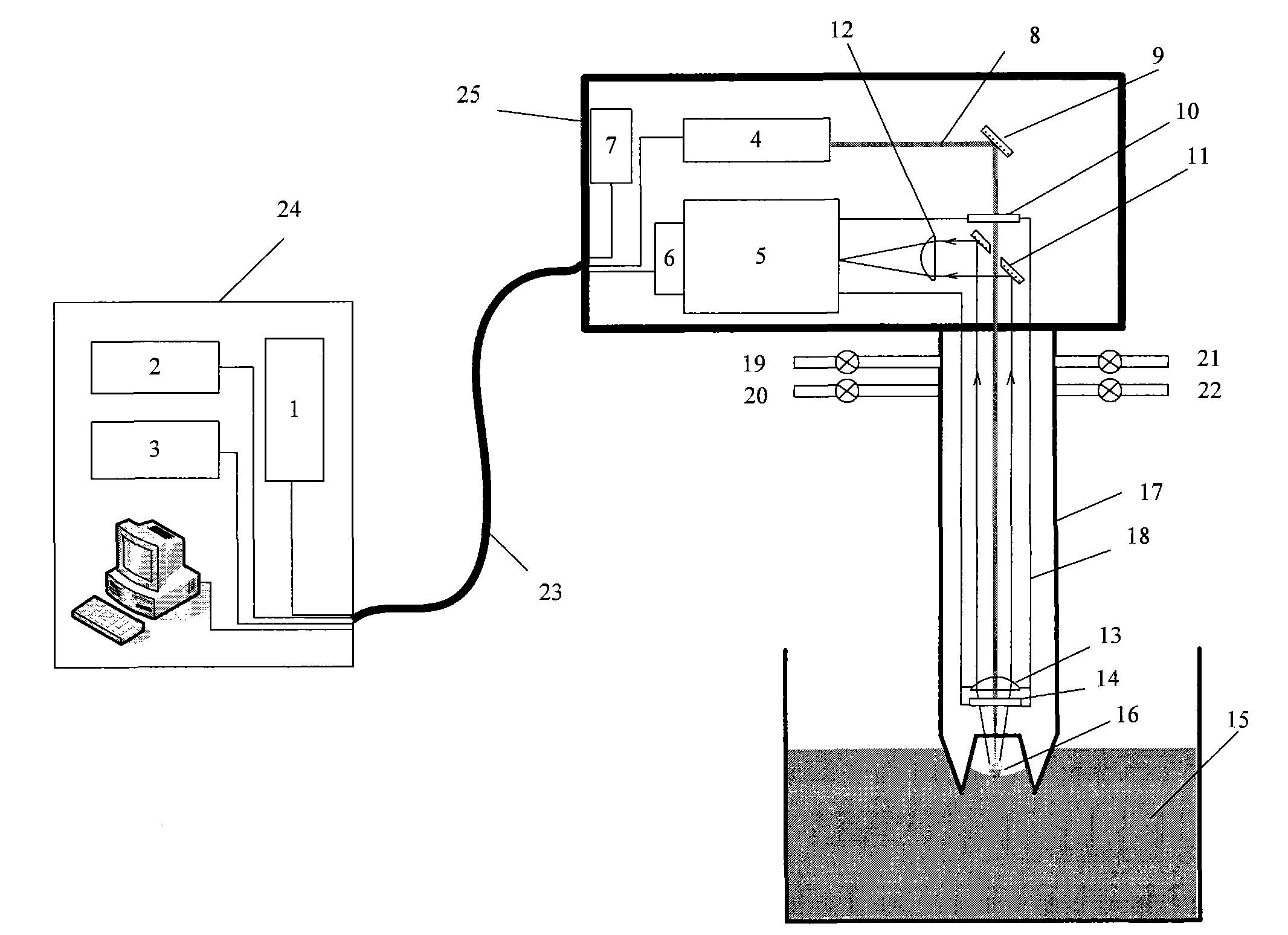

[0021] Such as figure 1 As shown, the in-situ and on-line detection device for metallurgical liquid metal components of the present invention includes a front end high temperature resistant optical probe, a middle end signal generating and collecting part, and a back end control platform. Among them: the front end high temperature resistant optical probe 17 has a metallurgical liquid at its front end. In the metal 15, the optical signal is generated and sent to the mid-end signal generation and collection part; the mid-end signal generation and collection part converts the received optical signal of the front-end high temperature resistant optical probe 17 into an electrical signal, and outputs it to the back-end control platform; The back-end control platform, as a manual operation and display platform, receives the electrical signals sent by the mid-end signal generation and collection part for processing; controls the mid-end signal generation and collection part of the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com