Zinc oxide-based wide bandgap ceramic target and preparation method thereof

A zinc oxide-based, ceramic target material technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of expensive RF power supply and difficulty in large-scale use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

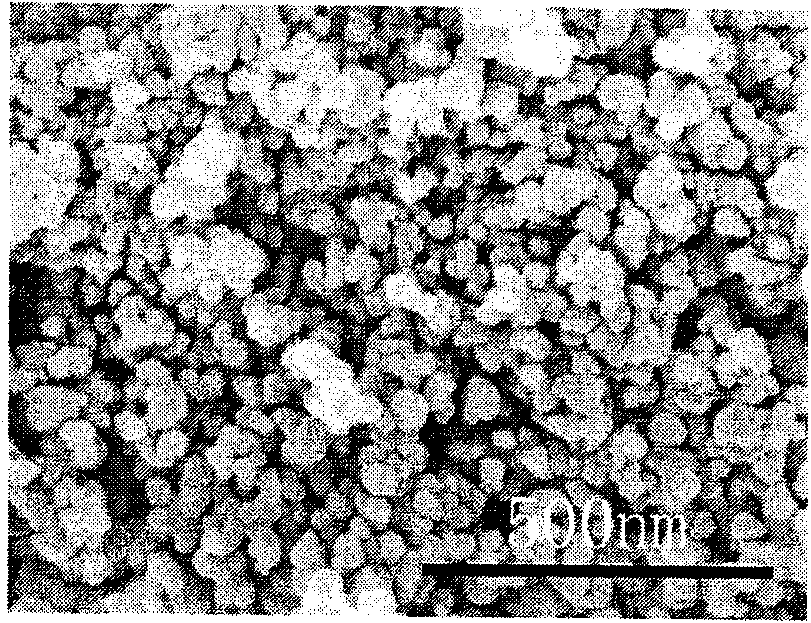

[0028] The zinc source and the oxygen source are mixed according to the molar ratio and undergo co-precipitation reaction, and then mixed, dried and ground to obtain a highly active and highly crystalline nano-ZnO precursor powder, and then the high-performance precursor powder is granulated, By means of isostatic pressing and other means of compression molding, the ceramic biscuit with high compacted density is prepared. Two upper and lower crucibles are used, graphite is sunk in the lower crucible, and the pressed ZnO ceramic green body placed in the upper crucible is inverted on the lower crucible. With a sintering temperature of 750°C, during the sintering process, the airtight space formed by the upper and lower crucibles is an oxygen-deficient environment, and graphite is easy to form reducing CO gas, thus causing the target to form an oxygen-deficient or Zn-rich state during the preparation process . After about 16 hours of sintering, the oxygen-deficient ZnO 0.9 Stru...

Embodiment 2

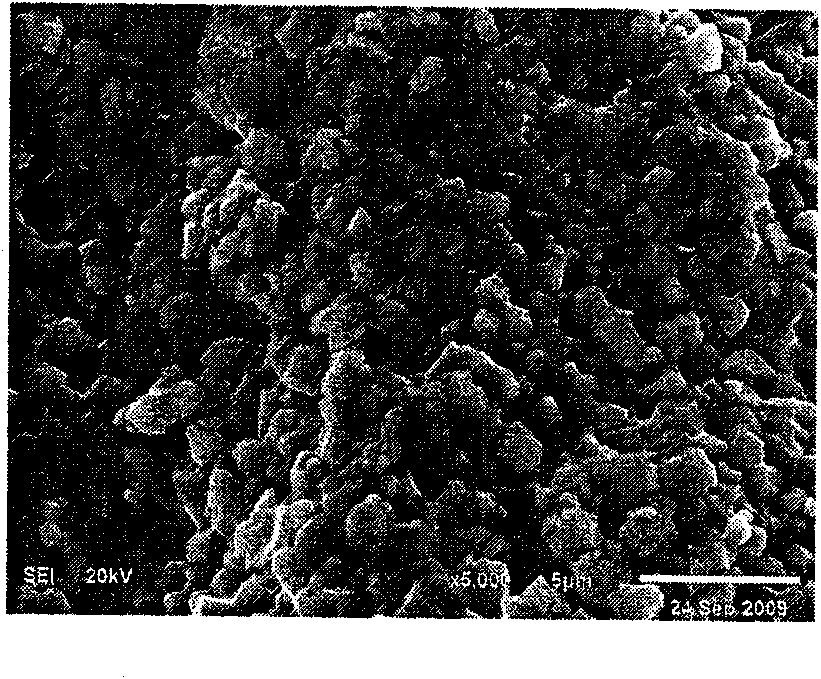

[0031] The zinc source and the oxygen source are mixed according to the molar ratio and undergo co-precipitation reaction, and then mixed, dried and ground to obtain a highly active and highly crystalline nano-ZnO precursor powder, and then the high-performance precursor powder is granulated, By means of isostatic pressing and other means of compression molding, the ceramic biscuit with high compacted density is prepared. Two upper and lower crucibles are used, graphite is sunk in the lower crucible, and the pressed ZnO ceramic green body placed in the upper crucible is inverted on the lower crucible. With a sintering temperature of 900°C, during the sintering process, the closed space formed by the upper and lower crucibles is an oxygen-deficient environment, and graphite is easy to form reducing CO gas, thus causing the target to form an oxygen-deficient or Zn-rich state during the preparation process . After about 2 hours of sintering, the oxygen-deficient ZnO 0.88 Struct...

Embodiment 3

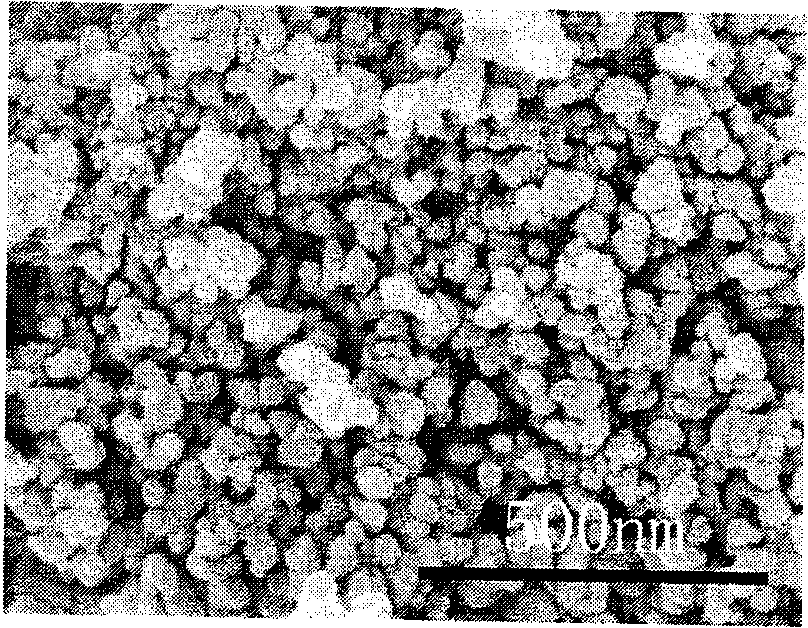

[0033]The zinc source and the oxygen source are mixed according to the molar ratio and undergo co-precipitation reaction, and then mixed, dried and ground to obtain a highly active and highly crystalline nano-ZnO precursor powder, and then the high-performance precursor powder is granulated, By means of isostatic pressing and other means of compression molding, the ceramic biscuit with high compacted density is prepared. Two upper and lower crucibles are used, graphite is sunk in the lower crucible, and the pressed ZnO ceramic green body placed in the upper crucible is inverted on the lower crucible. Using a sintering temperature of 850°C, during the sintering process, the airtight space formed by the upper and lower crucibles is an oxygen-deficient environment, and graphite is easy to form reducing CO gas, thus causing the target to form an oxygen-deficient or Zn-rich state during the preparation process . After about 20 hours of sintering, the zinc-rich Zn 1.13 O structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com