Method for recovering naphthenic acid from hydrocarbon oil and device thereof

A naphthenic acid and hydrocarbon oil technology, applied in the separation/purification of carboxylic acid compounds, only multi-stage series refining process treatment, organic chemistry, etc., can solve the problems of difficult stratification, high cost, serious emulsification, etc., and achieve Good economic and environmental benefits, reduced process costs, and reduced losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

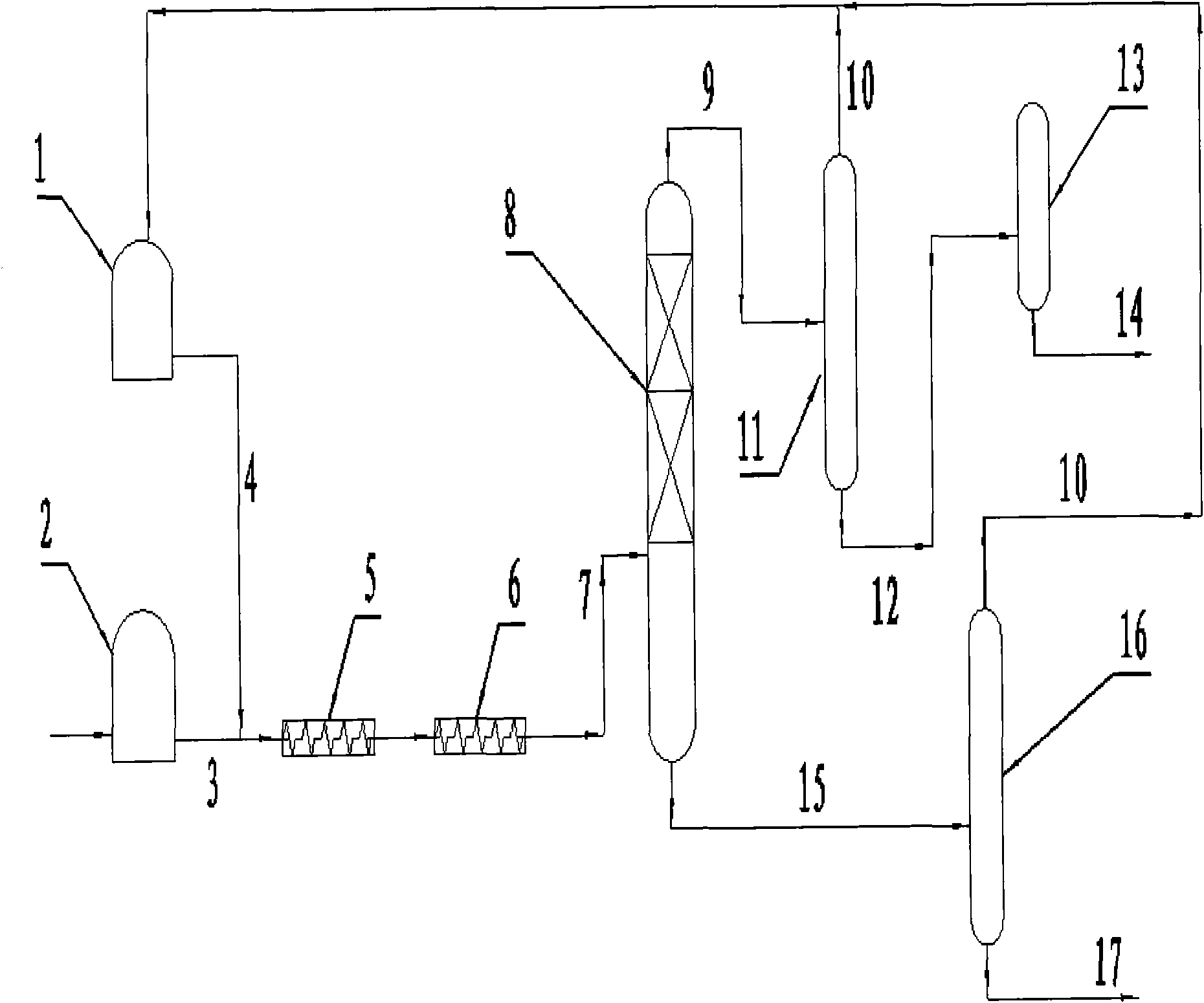

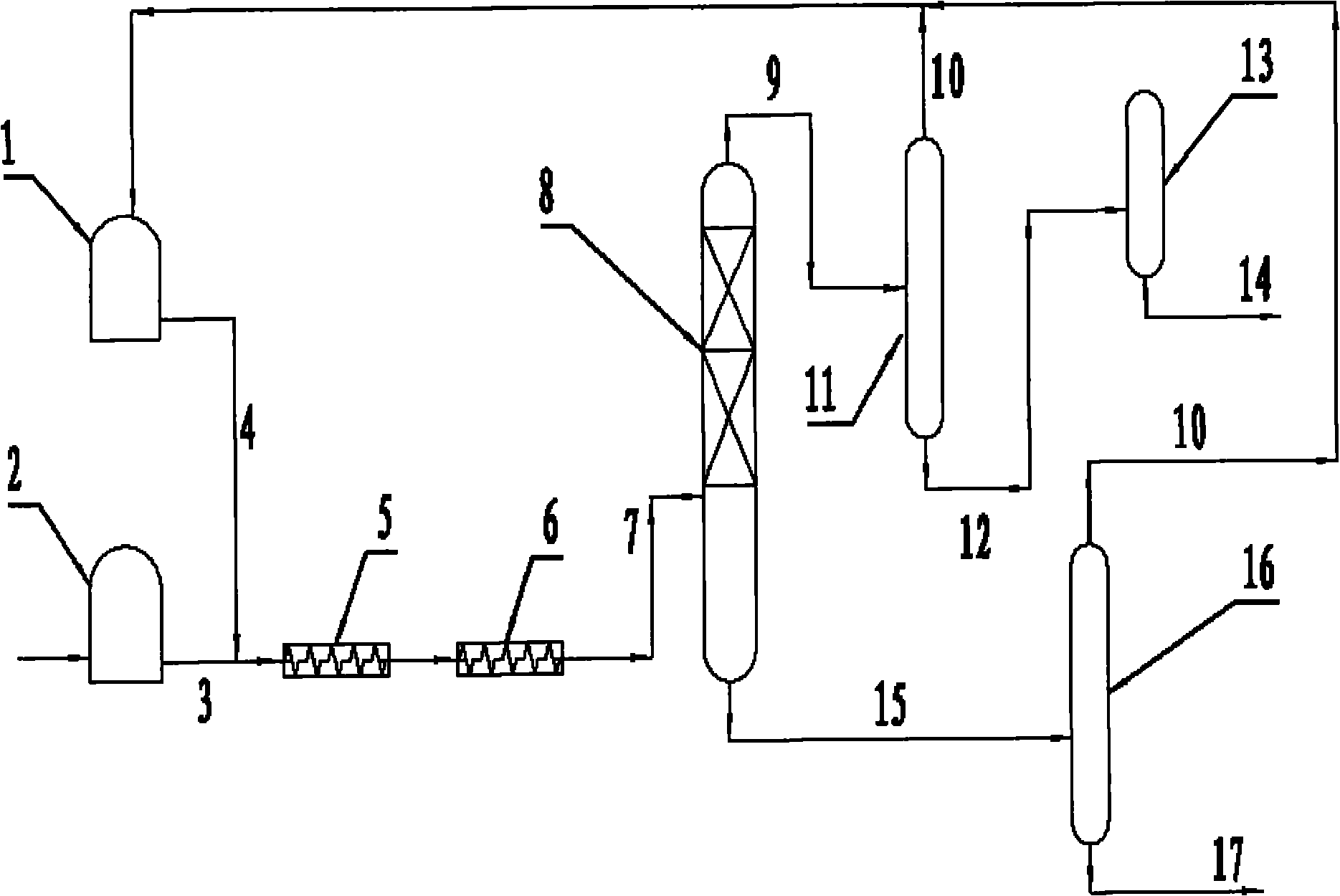

[0030] The raw material oil 3 with a boiling point greater than 150°C from the raw material buffer tank 2 and the deacidification solvent 4 from the deacidification solvent tank 1 successively enter the first static mixer 5 and the second static mixer 6 for mixed reaction; the oil after the mixed reaction The agent mixture 7 enters the settling separation tower 8, and the oil agent mixture 7 settles and separates into two phases in the settling separation tower 8. The upper layer is the deacidification solvent 9 containing naphthenic acid, and the lower layer is the agent-containing raw material oil 15 after deacidification; After the deacidification of the separation tower 8, the agent-containing raw material oil 15 enters the raw material distillation tower 16, and a small amount of recovered deacidification solvent 10 carried by the raw material oil 3 is evaporated from the top of the tower and returned to the deacidification solvent tank 1 for recycling, and discharged from ...

Embodiment 2

[0037] Technological process is with example 1.

[0038] Process conditions are as follows in the present embodiment:

[0039] Raw material oil: Beijiang crude oil, total acid value 3.66mgKOH / g

[0040] The composition of deacidification solvent: ethanol 78% (weight), water 20.2% (weight), ammonia 1.8% (weight)

[0041] Process conditions: reaction temperature 75°C, reaction time 5min, settling temperature 75°C, settling time 30min, deacidification solvent / crude oil mass ratio 1.

[0042] The acid value of Beijiang crude oil after deacidification is 0.54mgKOH / g, and the deacidification rate is 85.2%.

Embodiment 3

[0044] Technological process is with example 1.

[0045] Process conditions are as follows in the present embodiment:

[0046] Raw material oil: Penglai crude oil, total acid value 3.20mgKOH / g

[0047] The composition of deacidification solvent: ethanol 68% (weight), water 30.5% (weight), ammonia 1.5% (weight)

[0048] Process conditions: reaction temperature 80°C, reaction time 10min, settling temperature 80°C, settling time 45min, deacidification solvent / crude oil mass ratio 1.

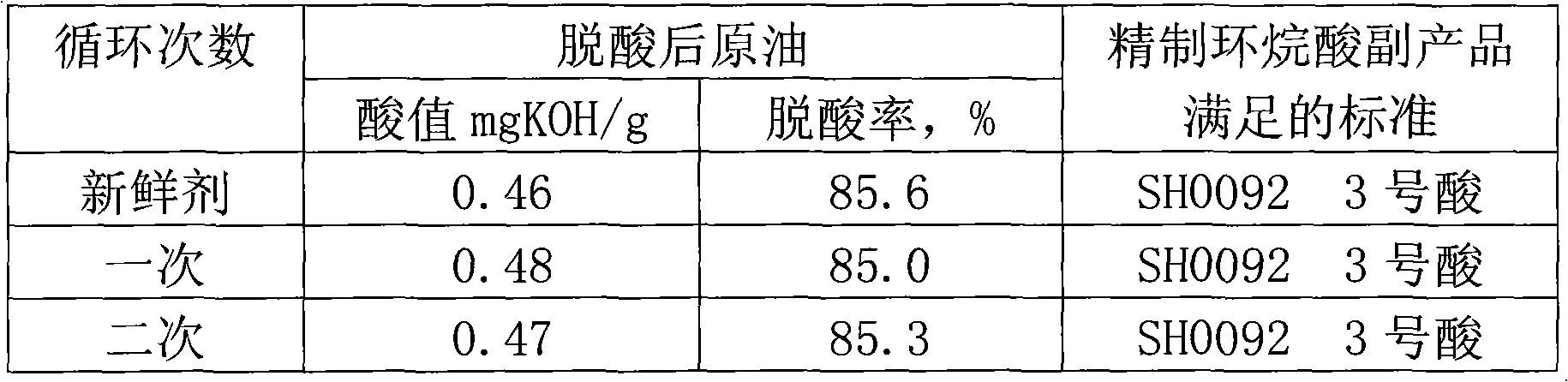

[0049] The acid value of Penglai crude oil after de-acidification is 0.46mgKOH / g, and the de-acidification rate is 85.6%. The refined naphthenic acid by-product obtained by the measurement conforms to the SH0092 No. 3 acid standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Total acid value | aaaaa | aaaaa |

| Total acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com