Wet washing device and cooling method during flue gas washing

A wet scrubbing and flue gas technology, which is applied in the field of flue gas purification, can solve the problems of poor cooling effect, low reliability and high flue gas temperature of accident spray devices, and achieves the elimination of thermal insulation materials and the effect of atomization. Good, small spray volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] It should be noted that the terms "first" and "second" in the description and claims of the present invention and the above drawings are used to distinguish similar objects, but not necessarily used to describe a specific sequence or sequence.

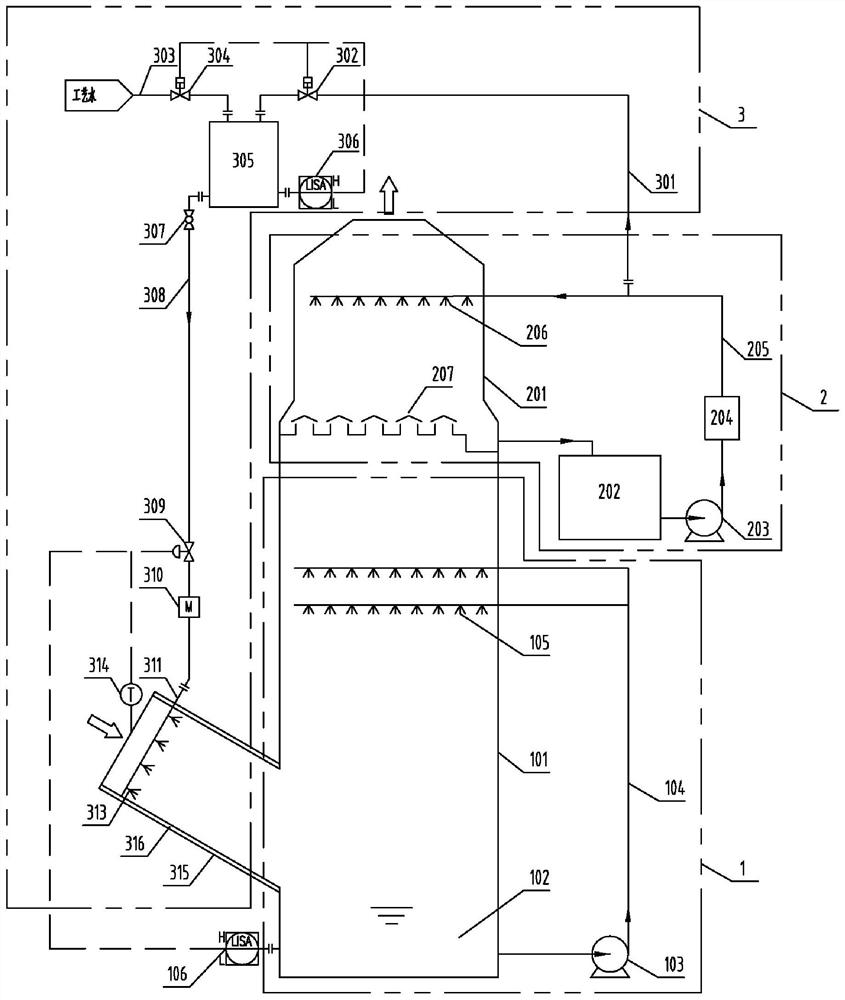

[0025] See figure 1 , The embodiment of the present invention provides a wet scrubbing device, which is used for wet deacidification and whitening of garbage incineration. The wet scrubbing device includes a smoke cleaning circulation system 1 , a dehumidification circulation system 2 and an inlet spraying system 3 . The flue gas is cooled by the inlet spray system 3, washed by the smoke washing circulation system 1 and dehumidified by the dehumidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com