UV curing silver nanowire ink and its preparation method and application method

A silver nanowire and solidification technology, which is applied in the field of silver nanowire ink and its preparation, can solve problems such as complicated process, and achieve the effect of simple process, simple and convenient preparation method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a UV-curable silver nanowire ink, a preparation method and a use method thereof, that is, a one-step method is used to prepare a transparent conductive film with a certain pattern. The present invention prepares a silver nanowire ink containing a UV-curable epoxy resin mixture, and then forms a thin film of the ink on a transparent substrate through a one-step method, and removes the ink in the uncured area after selective UV irradiation, thereby forming a silver nanowire ink with A transparent conductive film with a specific pattern. The UV-curable epoxy resin mixture can be selectively cured according to the pattern requirements, and the one-step method greatly simplifies the production process of the silver nanowire transparent conductive film, and has good practical application value. The present invention is described in detail below:

[0042] UV curable silver nanowire ink, said silver nanowire ink is made up of silver nanowire, epoxy resin...

Embodiment 1

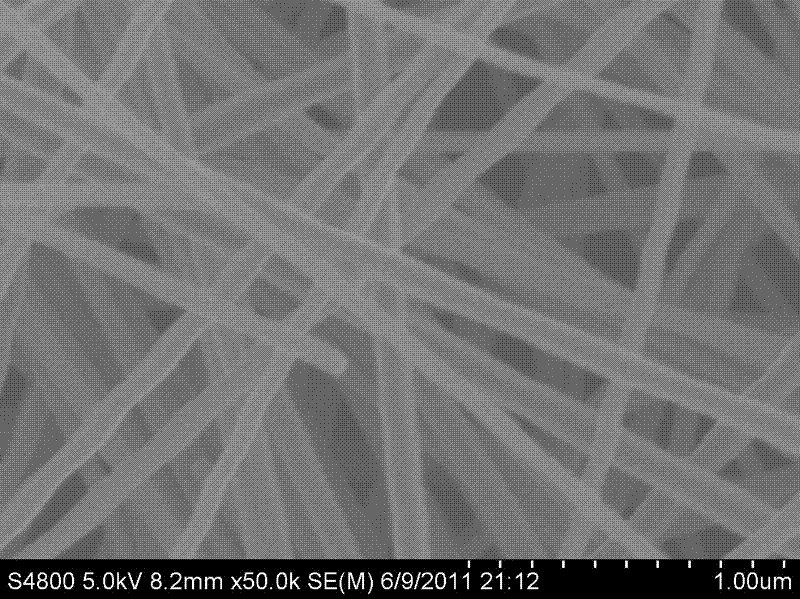

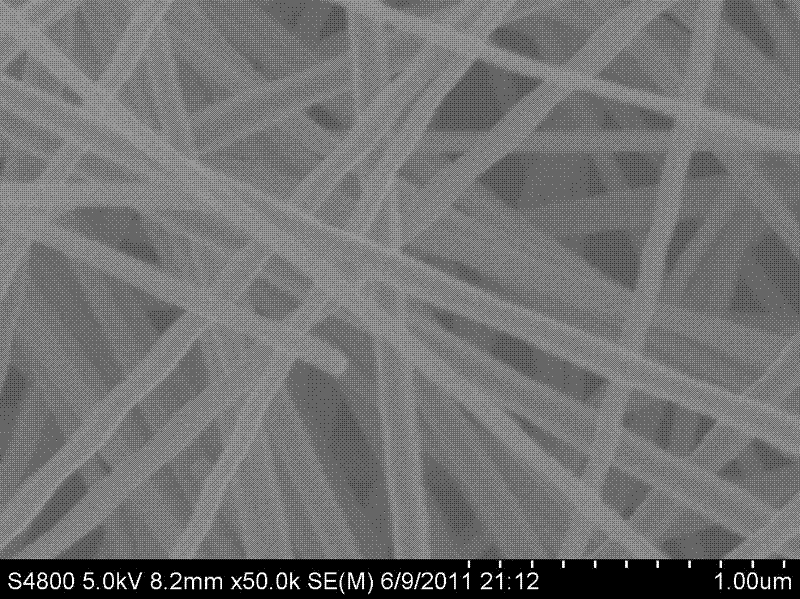

[0072] In a 500mL three-necked flask with a stirrer, add 30g of E51 epoxy resin, 0.9g of triarylsulfonium hexafluoroantimonate, 0.6g of benzophenone, and 150g of acetone, stir at room temperature until uniform, and add silver nanowire ethanol solution (5mg / mL, average diameter 90nm, average length 30μm) 300g, stirred for 30min, after mixing evenly, the silver nanowire ink was prepared.

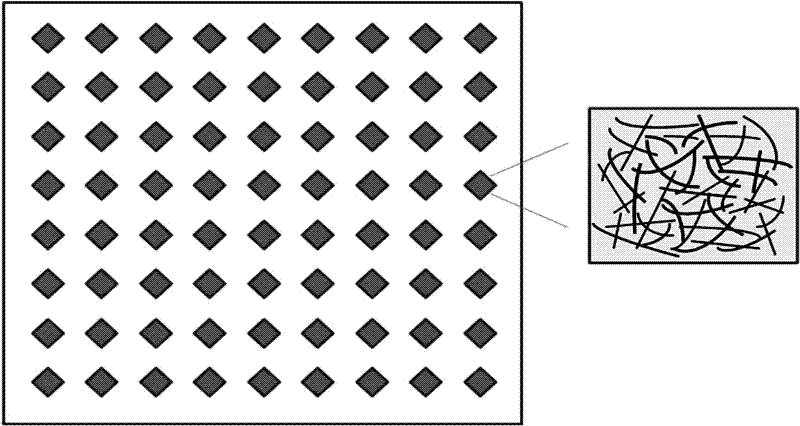

[0073] The corona-treated PET is used as a transparent substrate (visible light transmittance 91.8%), and the silver nanowire ink is used to form a uniform film layer on the substrate by spin coating. After the solvent is evaporated, the surface is covered with a diamond pattern mask , exposed at 10 cm under a 600W high-pressure mercury lamp for 10 minutes, washed with acetone / ethanol mixed solvent (V / V=1 / 1) to remove the uncured part, and then subjected to a pressure treatment of 30 atm to obtain a transparent conductive material with a diamond pattern. film. The visible light transmittance ...

Embodiment 2

[0075] Add 20g of CY179 epoxy resin, 1.0g of ferrocenetetrafluoroborate, 0.8g of dibenzoyl peroxide, and 100g of tetrahydrofuran into a 500mL three-necked flask with a stirrer, stir at room temperature until uniform, add silver nanowire iso Propanol solution (15mg / mL, average diameter 70nm, average length 15μm) 150g, stirred for 30min, after mixing evenly, the silver nanowire ink was prepared.

[0076] The surface of the PC treated with UV ozone is used as a transparent substrate (visible light transmittance 90.5%), and the silver nanowire ink is sprayed to form a uniform film layer on the substrate. After the solvent is evaporated, the surface is covered with a diamond pattern mask. Expose at 15 cm under a 700W high-pressure mercury lamp for 10 minutes, wash with acetone / isopropanol mixed solvent (V / V=1 / 2) to remove the uncured part, and then perform 150 o C heat treatment for 30min to obtain a transparent conductive film with a rhombus pattern. The visible light transmittan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com