Copper salt absorption liquid for desorbing arsenic hydride from ethane and propene in gas phase and application thereof

An arsine and absorbing liquid technology, applied in absorption purification/separation, organic chemistry, material separation, etc., can solve the problems of imperfect monitoring system, loss of purification production equipment, unsatisfactory dearsenic removal efficiency, etc., and achieve the cost of use Low, easy-to-obtain, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

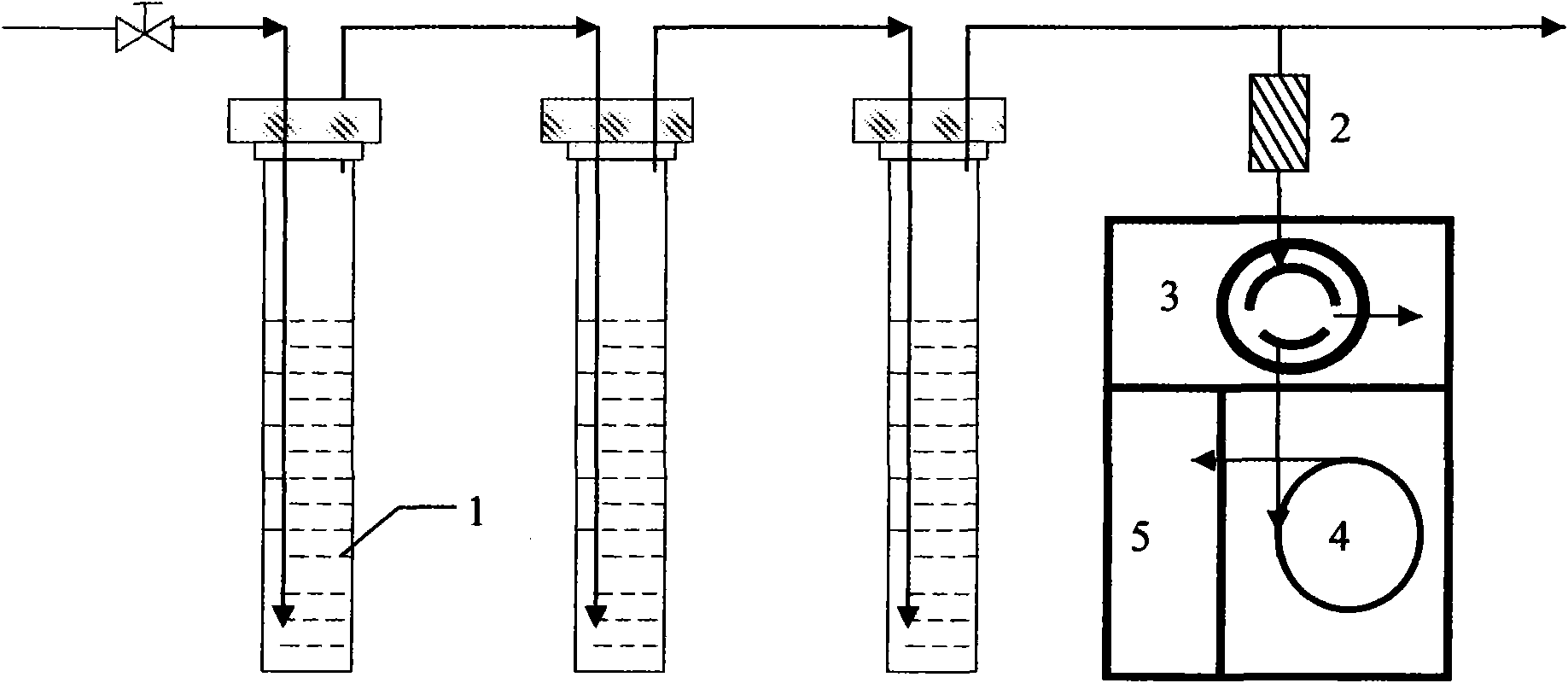

[0014] The arsine content of propylene in the refinery is 910ppb (volume fraction) after preliminary purification, and 0.26mol / L bromine aqueous solution: 30%H 2 o 2 Solution: 0.2mol / L copper chloride solution is mixed according to the volume ratio of 3:3:1, the concentration of bromine water in the mixed solution is 0.11mol / L, the concentration of hydrogen peroxide is 3.7mol / L, and the concentration of copper chloride is 0.03mol / L L, then adjust the pH value to 3 with 1:1 concentrated hydrochloric acid and concentrated nitric acid, and then pack it into a 60mm in diameter and 250mm long airtight purification absorber, and keep the temperature of the mixed solution at 70°C. Propylene containing 910ppb (volume fraction) of arsine passes through the first-stage absorption liquid (1) at a flow rate of 100mL / min and is directly connected to the six-way valve (3) for sampling of the monitoring system. The six-way valve is equipped with a quantitative loop Continuous quantitative s...

Embodiment 2

[0016] 0.26mol / L bromine aqueous solution: 30% H 2 o 2 Solution: 0.2mol / L copper chloride solution is mixed according to the volume ratio of 3:3:1, the concentration of bromine water in the mixed solution is 0.11mol / L, the concentration of hydrogen peroxide is 3.7mol / L, and the concentration of copper chloride is 0.03mol / L L, then use 1:1 concentrated hydrochloric acid and concentrated nitric acid to adjust the pH value to 3, then put it into three purification adsorbers with a diameter of 0.1m and a length of 1m, and keep the temperature of the mixed solution at 30°C. Refinery propylene containing arsine 910ppb (volume fraction) is purified and absorbed through the three-stage series absorption solution (1) at a flow rate of 1.2L / min, and then connected to the sampling six-way valve of the monitoring system through the bypass dryer (2) (3), the six-way valve is equipped with a quantitative loop to realize continuous quantitative sampling, and the sampling interval is 20 minu...

Embodiment 3

[0018] The refinery propylene monitors after preliminary purification and finds that the arsine content is 910ppb (volume fraction), and 0.26mol / L bromine aqueous solution: 30%H 2 o 2 Solution: 0.2mol / L copper sulfate solution is mixed in a volume ratio of 4:4:1, the concentration of bromine water in the mixed solution is 0.12mol / L, the concentration of hydrogen peroxide is 3.9mol / L, and the concentration of copper sulfate is 0.02mol / L. Then use 1:1 concentrated hydrochloric acid and concentrated nitric acid to adjust the pH value to 2 and then pack it into a purification adsorber with a diameter of 60 mm and a length of 250 mm, and the temperature of the mixed solution is kept at 70°C. Propylene containing trace arsine 910ppb (volume fraction) is purified and absorbed through the primary absorption liquid (1) at a flow rate of 80mL / min, and then directly connected to the six-way valve (3) for sampling of the monitoring system. The six-way valve is equipped with The quantitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com