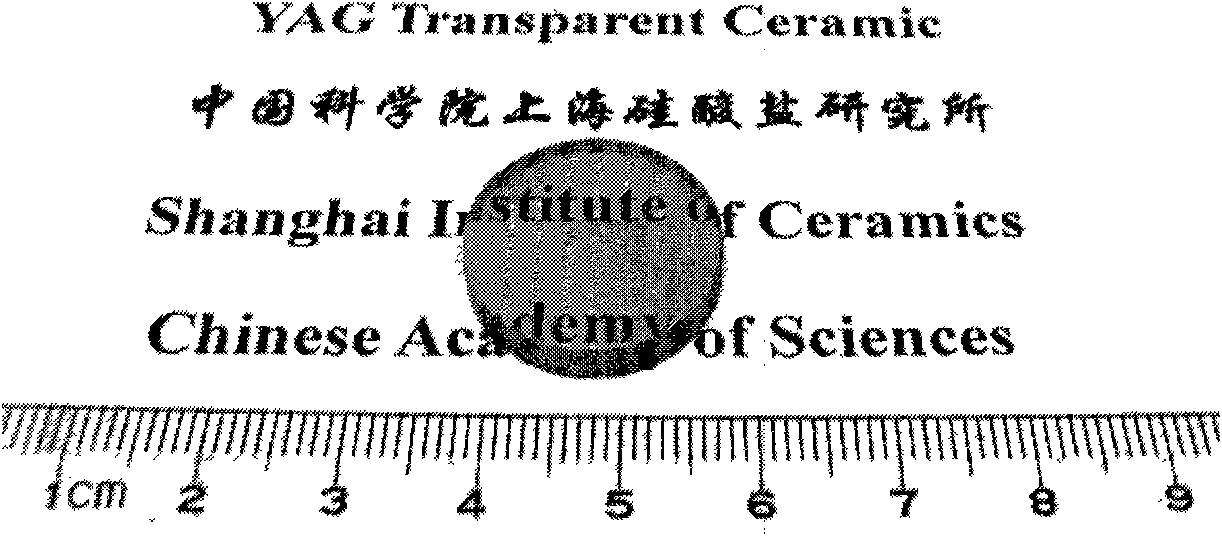

Active ion controlled doping yttrium aluminum garnet base laser transparent ceramic material and preparation method thereof

A technology of yttrium aluminum garnet and activated ions is applied in the field of transparent ceramic preparation, which can solve the problems of aggravating lattice distortion, affecting the optical quality of ceramic materials, and not being developed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the first aspect of the present invention, a method for preparing yttrium-aluminum-garnet-based laser-transparent ceramic materials with controlled doping of activated ions is provided, specifically, a controlled doping of Cr, Nd or Cr, Yb is provided. The preparation method of miscellaneous YAG transparent ceramics, this method comprises the following steps:

[0031] (i) Raw material selection:

[0032] The raw material can be:

[0033] (a) High-purity α-Al 2 o 3 , Y 2 o 3 、Cr 2 o 3 、Nd 2 o 3 (or Yb 2 o 3 ) powder;

[0034] (b) High-purity Cr:YAG, Nd:YAG (or Yb:YAG) powder;

[0035] (ii) Selection of sintering aids:

[0036] The sintering aid can be LiF, NaF, MgF 2 , CaF 2 , AlF 3 , Li 2 O, Na 2 O, K 2 O, CaO, MgO, B 2 o 3 , Ga 2 o 3 、Sc 2 o 3 , La 2 o 3 , SiO 2 , silica gel, TEOS (orthoethyl silicate), and the addition of the sintering aid is 10 2 -10 6 ppm;

[0037] Wherein, the purity of the above-mentioned commercial raw materials ...

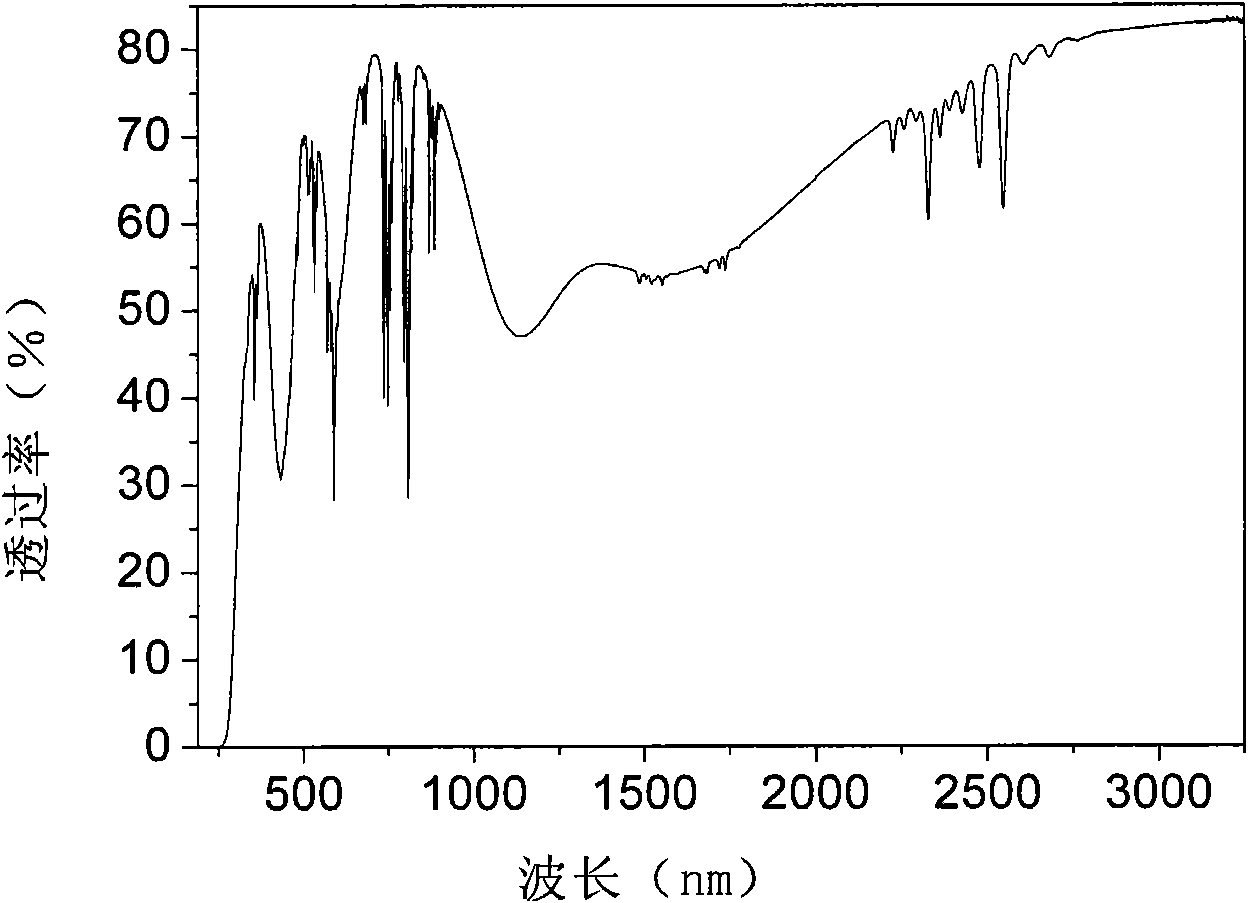

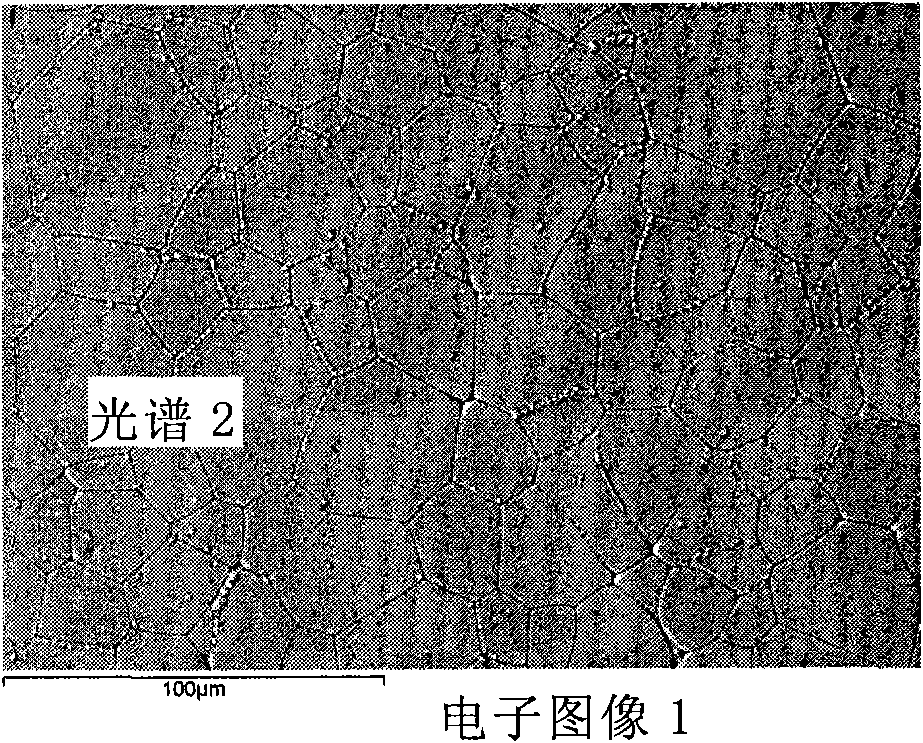

Embodiment 1

[0052] Prepare two ethanol-based slurries with different compositions: (1) 25.3629g of α-Al with an average particle size of 300nm 2 o 3 Powder, 33.5328g of Y with an average particle size of about 3μm 2 o 3 Powder, 0.1900g of Cr with an average particle size of about 1μm 2 o 3 Put the powder and 0.3565g tetraethyl orthosilicate (TEOS) into a ball mill jar equipped with 200g high-purity alumina balls, add 34ml of absolute ethanol, and then ball mill and mix for 10 hours to obtain ceramic slurry "a"; (2 ) 25.4904g of α-Al with an average particle size of 300nm 2 o 3 Powder, 33.8715g of Y with an average particle size of about 3μm 2 o 3 Powder, 0.5047g of Nd with an average particle size of about 250nm 2 o 3 Put the powder and 0.3869g tetraethyl orthosilicate (TEOS) into a ball mill jar equipped with 200g high-purity alumina balls, add 34ml of absolute ethanol, and then ball mill and mix for 10 hours to obtain ceramic slurry "b". The two slurries were dried in an oven ...

Embodiment 2

[0054] Prepare two kinds of ethanol-based slurries with different compositions: (1) 25.2355g of α-Al with an average particle size of 300nm 2 o 3 Powder, 33.8715g of Y with an average particle size of about 3μm 2 o 3 Powder, 0.3800g of Cr with an average particle size of about 1μm 2 o 3 Put the powder and 0.3272g tetraethyl orthosilicate (TEOS) into a ball mill jar equipped with 200g high-purity alumina balls, add 35ml of absolute ethanol, and then ball mill and mix for 10 hours to obtain ceramic slurry "c"; (2 ) 25.4904g of α-Al with an average particle size of 300nm 2 o 3Powder, 33.1955g of Y with an average particle size of about 3μm 2 o 3 Powder, 1.0094g of Nd with an average particle size of about 250nm 2 o 3 Put the powder and 0.3582g tetraethyl orthosilicate (TEOS) into a ball mill jar equipped with 200g high-purity alumina balls, add 35ml of absolute ethanol, and then ball mill and mix for 10 hours to obtain ceramic slurry "d". The two slurries were dried in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com