Laser cladding quick precision manufacturing method and device based on laser milling

A laser milling and laser cladding technology, applied in manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems of increased surface hardness, lack of support conditions, long processing time, etc., to shorten the manufacturing process, suitable for promotion and use , the effect of high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

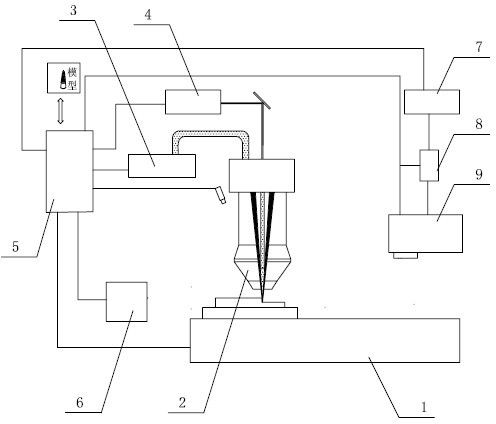

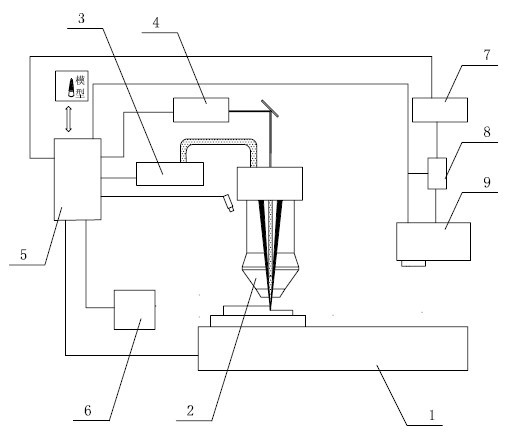

[0020] Example 1: see figure 1 As shown, a laser cladding rapid and precise manufacturing method based on laser milling includes the following steps:

[0021] (1) First, make a 3D solid model of the part to be manufactured, use the layered software of the control computer to preprocess to obtain the geometric information of each section of the part, and build a part shape detection system;

[0022] (2) Control the computer to control the laser and the powder feeder to spray the beam and powder beam through the coaxial powder feeding nozzle in the light to the surface of the substrate on the worktable to form a cladding layer for laser cladding manufacturing;

[0023] The CCD detector collects the digital image of the processing area of the workbench, and transmits it to the part shape detection system of the control computer to measure the height and section size of the part in real time;

[0024] ⑷ The part shape detection system compares the part information collected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com