Titanium-containing nickel-based catalyst, as well as preparation method and application thereof

A catalyst, titanium-nickel technology, applied in the field of titanium-nickel-based catalysts, to achieve the effects of reducing carbon deposition, improving hydrothermal stability, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

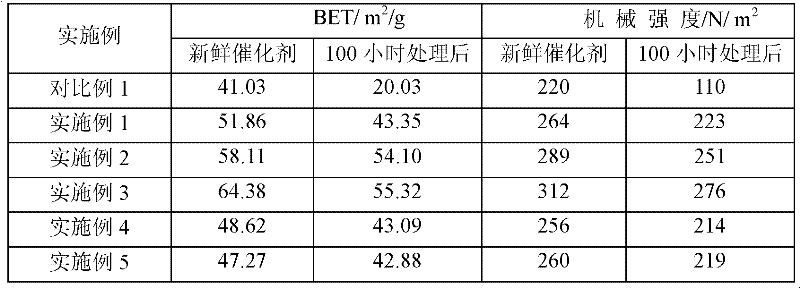

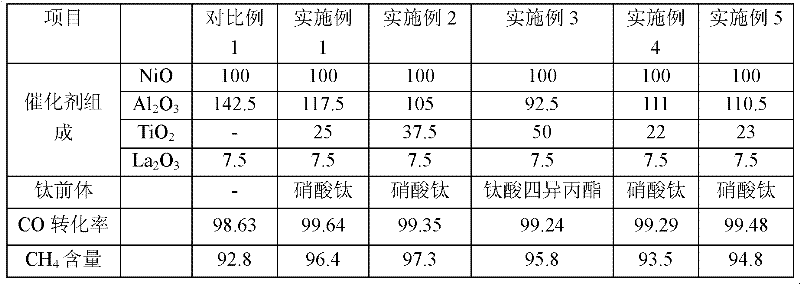

Examples

preparation example Construction

[0110] In a more preferred embodiment, the preparation method of the present invention comprises the following steps:

[0111] (a) dissolving nickel nitrate, lanthanum nitrate, titanium compound (or titanium precursor) in deionized water, removing insoluble impurities, and keeping the solution temperature at 40-80°C;

[0112] (b) Use 10% to 20% ammonium bicarbonate aqueous solution as a precipitant, add the precipitant to the solution obtained in step (a), preferably co-precipitate nickel, lanthanum, titanium compounds (or titanium precursors) by co-current continuous pumping body) aqueous solution, and keep the precipitation temperature at a temperature of 30-90°C, and keep stirring at a pH of 6-9. After the precipitation is completed, continue to keep aging at 30-90°C for 1-8 hours.

[0113] (c) Filtrate and wash the precipitated slurry obtained in the previous step, and control the conductivity and the content of impurity ions such as acid radicals within the allowable rang...

Embodiment 1

[0129] Respectively 779 grams of nickel nitrate nonahydrate, 39.87 grams of lanthanum nitrate and 1157.6 grams of titanium nitrate-nitric acid solution (16%) are dissolved (diluted) in distilled water respectively, are mixed with 15% nickel nitrate solution, and then mixed with 10% nitric acid Mix the lanthanum solution evenly, and at the same time dilute the titanium nitrate-nitric acid solution into a 5% titanium nitrate aqueous solution, and dissolve at the same time to obtain a 15% sodium carbonate solution. Use a peristaltic pump to add the above-mentioned solutions to a 10L stirring tank, jacketed The heating temperature was kept at 70°C, the transmission speed of the peristaltic pump was carried out according to the metering ratio of the acidic and alkaline solutions, and the precipitation was completed under the conditions of a stirring rate of 100 rpm and a pH of 7.0, and aging for 1 hour. The resulting sedimented slurry was washed with a centrifuge and deionized water...

Embodiment 2

[0131] 779 grams of nickel nitrate, 39.87 grams of lanthanum nitrate and 1736.43 grams of titanium nitrate-nitric acid solution (16%) were respectively dissolved (diluted) in distilled water to prepare 10% nickel nitrate solution, and then mixed with 10% lanthanum nitrate solution Mix evenly, dilute the titanium nitrate-nitric acid solution into 5% titanium nitrate aqueous solution, and dissolve at the same time to obtain a 15% sodium carbonate solution. Use a peristaltic pump to add the above-mentioned solutions to a 10L stirring tank and heat the jacket to keep the temperature At 70°C, the transmission speed of the peristaltic pump should be carried out according to the metering ratio of acidic and alkaline solutions. Under the conditions of a stirring rate of 100 rpm and a pH of 7.0, the precipitation was completed and aged for 2 hours. The resulting sedimented slurry was washed with a centrifuge and deionized water for 4 times, and the conductivity of the filtrate was teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com