Method and device for detecting mist entrainment in multiphase flow equipment

A technology of mist entrainment and detection method, which is applied in the processing of detection response signals and the use of sonic/ultrasonic/infrasonic waves to analyze fluids. , Easy to use, small measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

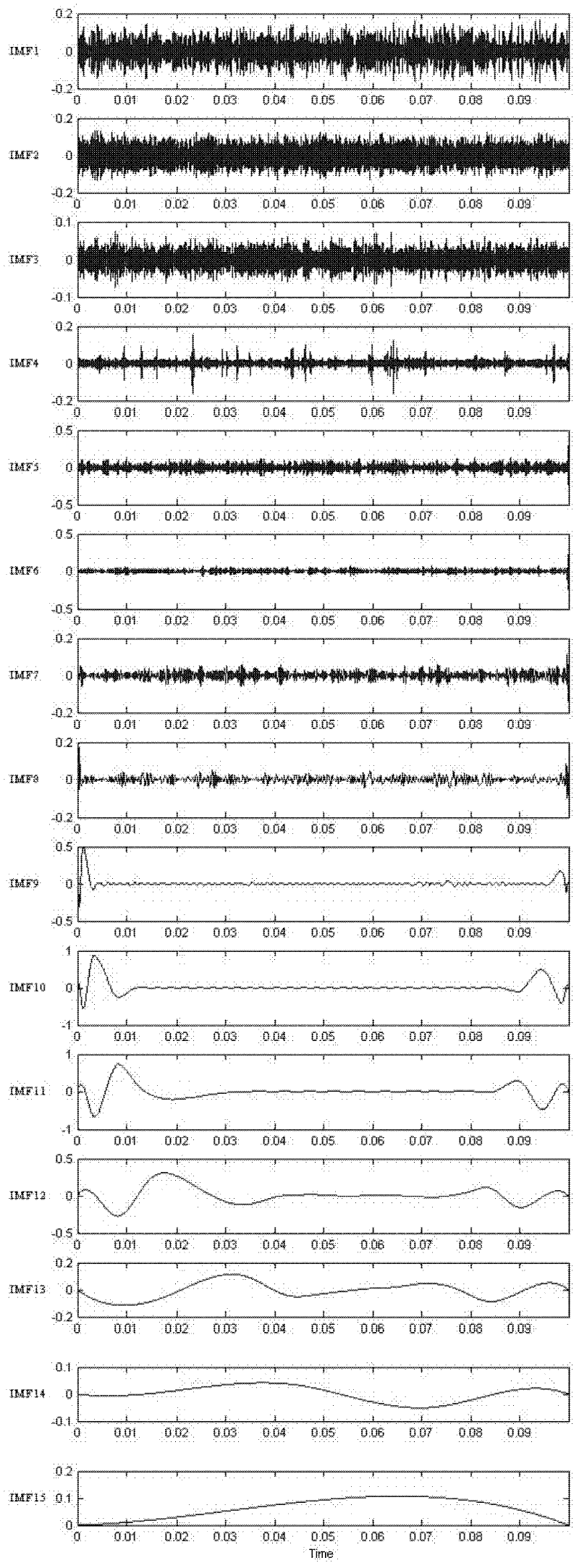

Embodiment 1

[0106] An industrial test was carried out in a slurry polyethylene production workshop with an annual output of 120,000 tons, and the acoustic emission technology was used to detect the entrainment of mist during the process of increasing the load of the polymerization kettle. Collect the vibration signal or acoustic wave signal when the amount of mist entrainment in the polymerization kettle is known; the collected vibration signal or acoustic wave signal is processed by HHT for multi-scale analysis, and the characteristic parameters are calculated; The parameter is the dependent variable, and the curve fitting method is used to establish a prediction model, that is, a regression model, which is used to monitor the mist entrainment in the polymerization kettle in real time.

[0107] In the polymerization tank, hexane is used as a solvent, and ethylene is passed through to carry out slurry polymerization to produce high-density polyethylene (HDPE). The hexane evaporated from t...

Embodiment 2

[0114] An industrial test was carried out in a slurry polyethylene production workshop with an annual output of 70,000 tons. The acoustic emission technology was used to detect the mist entrainment during the load drop of the polymerization kettle. Collect the vibration signal or acoustic wave signal when the amount of mist entrainment is known in the polymerization kettle; use FFT processing and wavelet decomposition to perform multi-scale analysis on the collected vibration signal or acoustic wave signal, and calculate the characteristic parameters; take the entrainment amount of mist as the independent variable , with the characteristic parameters as the dependent variable, the partial least squares method is used to establish a prediction model, that is, a regression model, which is used to monitor the mist entrainment in the polymerization tank in real time.

[0115] In the polymerization tank, hexane is used as a solvent, and ethylene is passed through to carry out slurry...

Embodiment 3

[0124] A cold mold device was established in the laboratory, and acoustic emission technology was used to detect and control the amount of mist entrainment at the top of the stirred tank.

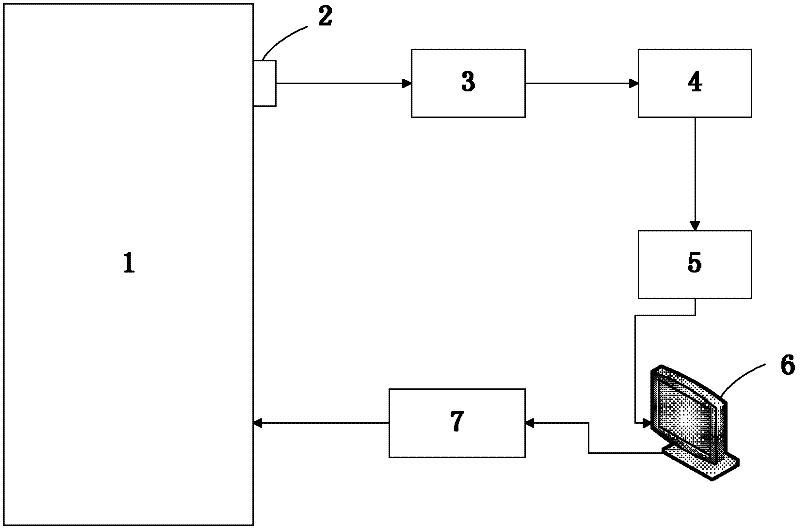

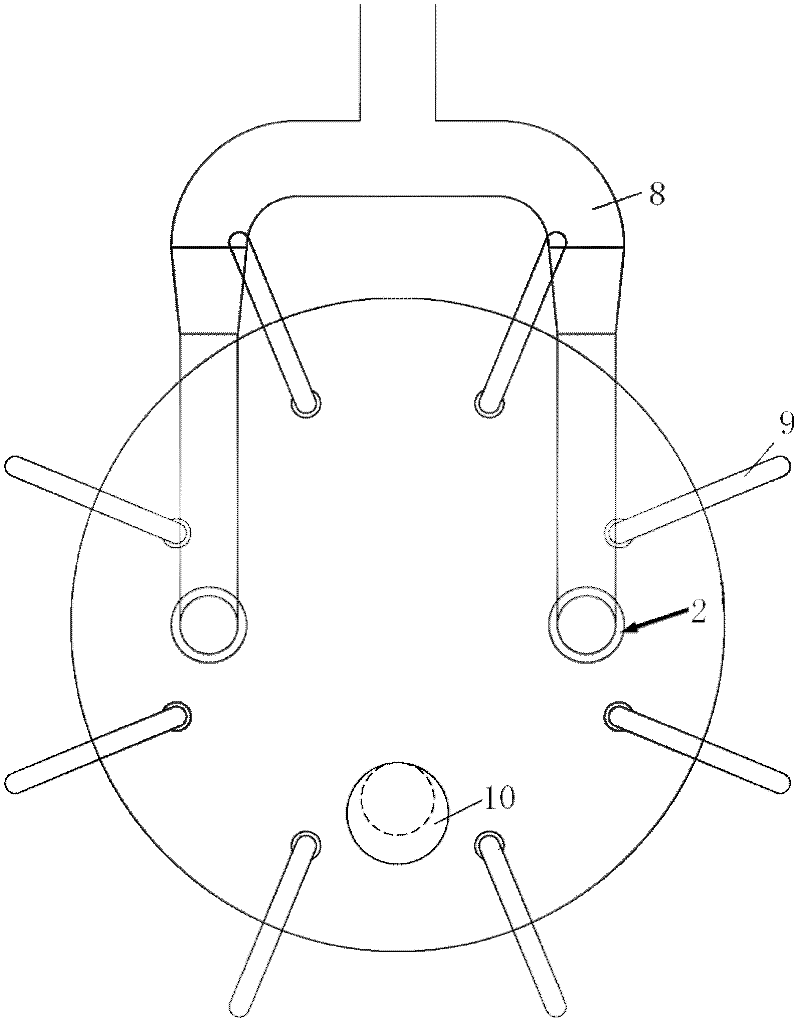

[0125] The detection and control system of mist entrainment in the stirred tank is attached Figure 14 As shown, the stirring tank 11 is a gas-liquid two-phase or gas-liquid-solid three-phase stirring system. The gas enters the tank through the inlet pipe, and when it flows out from the top of the tank, a small amount of liquid or liquid-solid mixture will be entrained. A mist entrainment collection device 13 is arranged on the top of the kettle to collect and measure the mist entrainment amount, which is used to establish an acoustic emission technology prediction model for the mist entrainment amount. The acoustic signal receiving device 2 is placed at the gas outlet of the tank top, and the received acoustic signal is amplified by the signal amplifier 3, collected by the signal acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com