A light-colored high-molecular-weight ganoderma polysaccharide and its preparation method

A technology of high molecular weight and Ganoderma lucidum polysaccharide, which is applied in the direction of antineoplastic drugs, drug combinations, allergic diseases, etc., can solve the problems of unfavorable large-scale production of product quality, difficult to control product quality, and harmful organic solvent residues, etc., to achieve enhanced anti-tumor The effect of high capacity, uniform distribution and high content of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Extraction of Ganoderma lucidum crude polysaccharides: using red lucidum fruiting body (Ganoderma lucidum strain with strain No. 2442 preserved in the strain preservation center of Edible Fungi Institute of Shanghai Academy of Agricultural Sciences, obtained through artificial cultivation) as raw material, crushed into coarse grains , weigh 2kg, add 20L water, soak at room temperature for 30min, heat to boiling, keep boiling slightly for 90min, and filter. Repeat the above steps for the filter residue, extract twice more, and combine the filtrates.

[0022] 2. Concentration of ganoderma lucidum crude extract: the filtrate is coarsely filtered with a 120-mesh filter screen (purchased from Shanghai Xinhua Wire Mesh Store), and then filtered with a 100-micron membrane (purchased from Shanghai Fleet Company), and the filtrate is concentrated under reduced pressure to 3L.

[0023] 3. Ethanol precipitation and washing: slowly add absolute ethanol to the concentrated solut...

Embodiment 2

[0028] 1. Extraction of Ganoderma lucidum crude polysaccharides: use red lucidum fruiting body (the bacterial strain No. Ganoderma lucidum 2442 preserved in the strain preservation center of the Institute of Edible Fungi, Shanghai Academy of Agricultural Sciences, obtained through artificial cultivation) as raw material, crushed into coarse grains , weigh 1.5kg, add 20L of water, soak at room temperature for 30min, heat to boiling, keep boiling slightly for 60min, and filter. Repeat the above steps for the filter residue, extract once more, and combine the filtrates.

[0029] 2. Concentration of ganoderma lucidum crude extract: the filtrate is coarsely filtered with a 120-mesh filter screen (purchased from Shanghai Xinhua Wire Mesh Store), and then filtered with a 100-micron membrane (purchased from Shanghai Fleet Company), and the filtrate is concentrated under reduced pressure to 2L.

[0030] 3. Ethanol precipitation and washing: Slowly add absolute ethanol to the concentra...

Embodiment 3

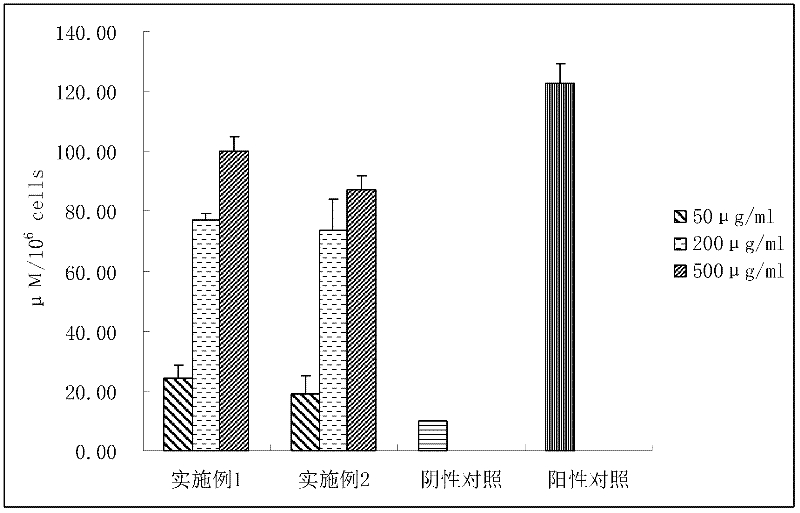

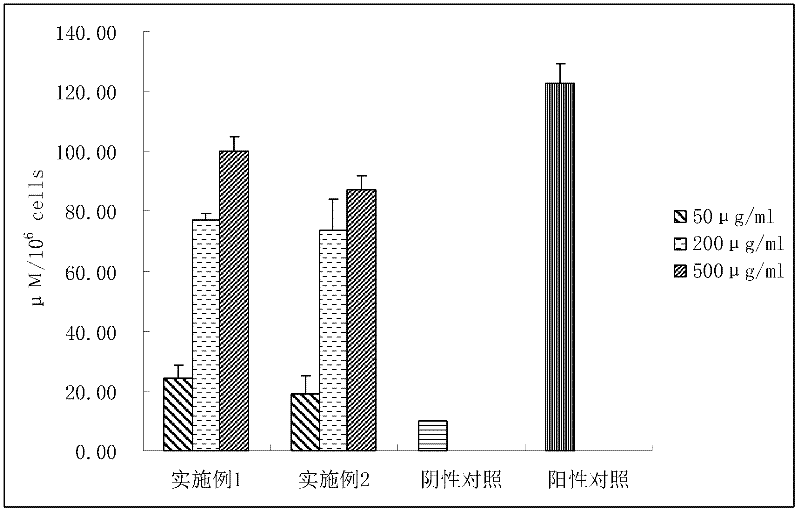

[0035] Determination of the activity of Ganoderma lucidum polysaccharide to stimulate macrophages to release NO in vitro:

[0036] 1. Sample preparation: Accurately weigh the Ganoderma lucidum polysaccharide samples prepared in Example 1 and Example 2 into a sterilized eppendorf tube, and prepare a sample solution with a concentration of 5 mg / mL with sterile PBS. After fully dissolving, centrifuge at 15000r / min for 30min, transfer the supernatant to a new sterile eppendorf tube under aseptic conditions, and dilute the sample to 2mg / ml and 0.5mg / ml for use.

[0037] 2. Cell culture: take the RAW264.7 macrophage cell line in the logarithmic growth phase (purchased from the Institute of Cells, Chinese Academy of Sciences), and use DMEM complete medium (purchased from Gibco) at 37 ° C, containing 5% CO 2 The cells were subcultured under conditions, digested with 0.05% trypsin or 5% EDTA solution, and the suspension was centrifuged at 1000rpm / min for 3min to collect the cells and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com