A four-station four-axis turning tool sharpening CNC machine tool

A CNC machine tool and four-station technology, which is applied in the direction of grinding machine parts, cutting tools for lathes, planing machines, etc., can solve the problem that sharpening efficiency affects production efficiency, it is difficult to ensure a reasonable cutting angle, and it is difficult to ensure that cutting tools Stability and other issues, to achieve fast and fully automated operation, facilitate standardized operation, and achieve the effect of standardized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

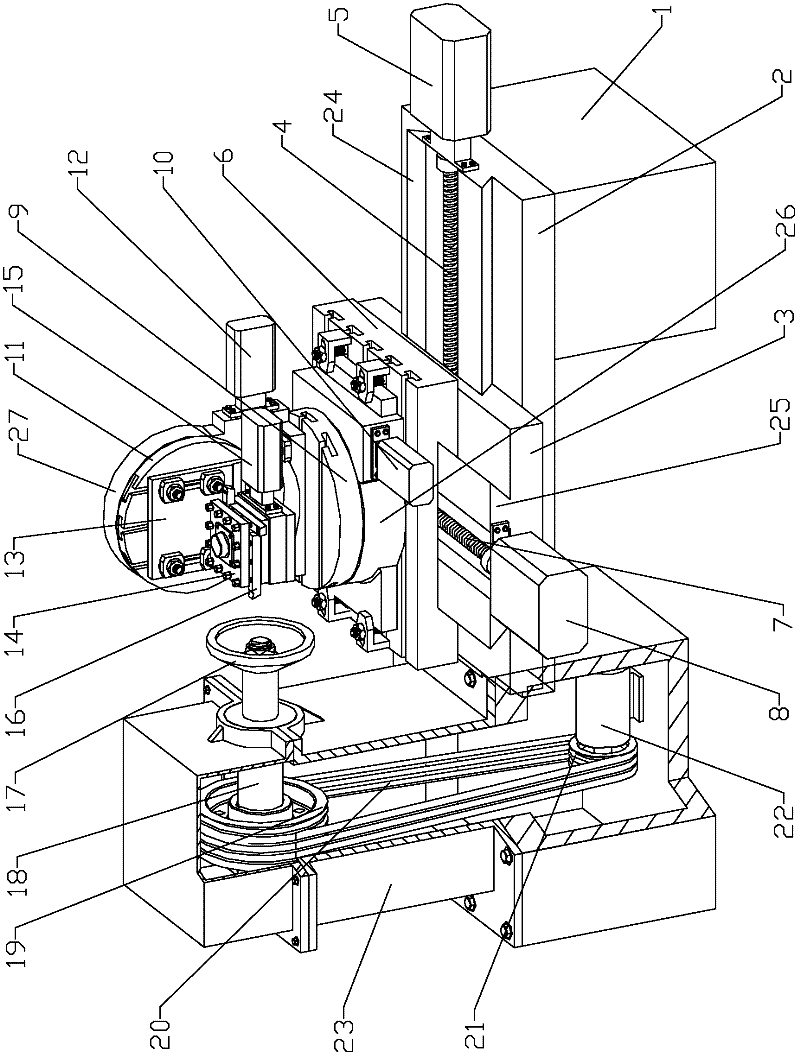

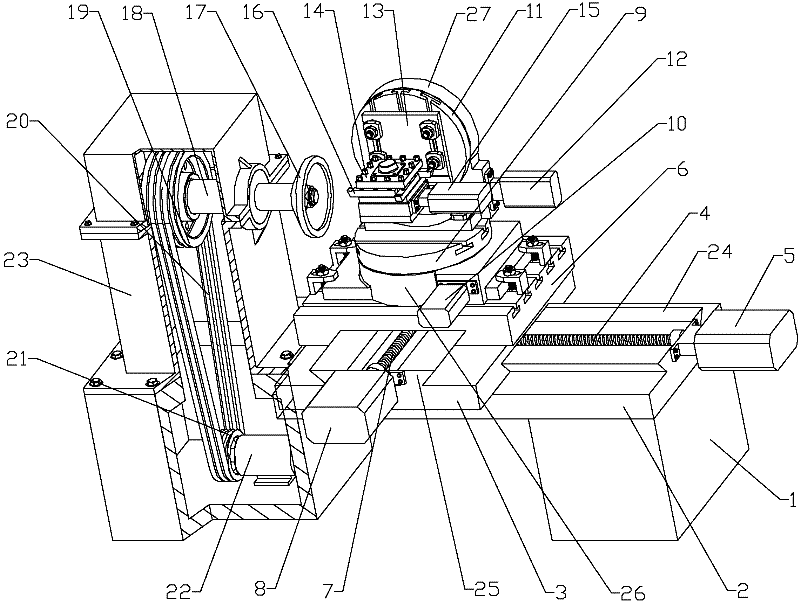

[0051] Embodiment, as shown in the accompanying drawings, a four-station four-axis turning tool sharpening CNC machine tool includes a machine bed body, and the machine tool bed body includes a bed leg 1 and a bed body 2 located on the bed leg 1;

[0052] A grinding wheel 17, an electric tool holder 14, a grinding wheel driving device and an electric tool holder driving device are arranged on the machine tool body, and the electric tool holder 14 is a four-station tool holder, which can simultaneously install four turning tools, and the order is controlled by the control system. Complete the grinding work of four turning tools;

[0053] The emery wheel driving device comprises emery wheel axle support 23, and emery wheel axle support 23 is arranged on the machine bed body, and the bed leg of emery wheel axle support 23 bottoms is provided with main motor 22, and the end of main motor 22 is provided with small pulley 21, and emery wheel axle The top of support 23 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com