Manufacturing process and products of heating mosquito repellent lamp

A production process and technology of mosquito repellent lamps, which are applied in the direction of chemicals, pest repellents, animal repellents, etc. for biological control, can solve problems such as radiation performance and unfavorable health, and achieve a simple and easy production process, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A manufacturing process of heating mosquito repellent lamp, said manufacturing process comprises the following steps:

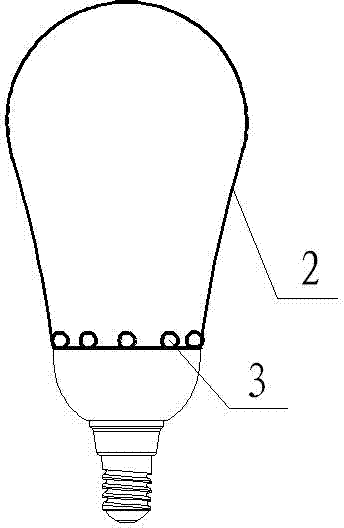

[0027] (1) Make a lamp tube with a hollow interlayer with a thickness of 1mm. At the same time, open multiple injection ports connected with the hollow interlayer on the upper part of the lamp tube. The injection ports are circular, and the injection ports are evenly arranged around the lamp tube (attached figure 1 );

[0028] (2) Then assemble the lamp tube processed in step (1) into a whole lamp;

[0029] (3) First, add 1 g of allethrin, 4 g of activated carbon, 30 g of iron powder, 14.7 g of silicic acid, 3 g of sodium silicate nonahydrate, 5 g of lavender oil, 2 g of piperonyl butoxide, 16 g of acid clay, chlorine Grind and mix 16 g of sodium chloride and 0.3 g of ether evenly, dry at room temperature for 1.5 hours, then add 8 g of white phosphorus, grind and mix evenly to form a powdery mosquito repellent mixture, and finally inject the powdery m...

Embodiment 2

[0031] A manufacturing process of heating mosquito repellent lamp, said manufacturing process comprises the following steps:

[0032] (1) Make a lamp tube with a hollow interlayer with a thickness of 2mm. At the same time, open multiple injection ports connected with the hollow interlayer on the upper part of the lamp tube. The injection ports are circular, and the injection ports are evenly arranged around the lamp tube (attached figure 2 );

[0033] (2) Then assemble the lamp tube processed in step (1) into a whole lamp;

[0034] (3) First mix 2 g of allethrin, 3 g of activated carbon, 32 g of iron powder, 13.5 g of silicic acid, 4 g of sodium silicate nonahydrate, 6 g of lavender oil, 4 g of piperonyl butoxide, 15 g of acid clay, Grind and mix 14 g of sodium chloride and 0.5 g of ether evenly, dry at room temperature for 3.5 hours, then add 6 g of white phosphorus, grind and mix evenly to form a powdery mosquito repellent mixture, and finally inject the powdery mosquito r...

Embodiment 3

[0036] A manufacturing process of heating mosquito repellent lamp, said manufacturing process comprises the following steps:

[0037] (1) Make a lampshade with a hollow interlayer with a thickness of 3mm. At the same time, open multiple injection ports connected with the hollow interlayer on the upper part of the lampshade. The injection ports are circular, and the injection ports are evenly arranged around the lampshade (attached image 3 );

[0038] (2) Then assemble the lampshade processed in step (1) into a complete lamp;

[0039] (3) 1.5g of allethrin, 3.5g of activated carbon, 31g of iron powder, 12g of silicic acid, 3.5g of sodium silicate nonahydrate, 5.5g of lavender oil, 3g of piperonyl butoxide, 16g of acid clay, and 16g of sodium chloride Grind and mix with ether 0.5g, dry at room temperature for 2 hours, then add white phosphorus 7.5g, grind and mix evenly to form a powdery mosquito repellent mixture, and finally inject the powdery mosquito repellent mixture into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com