Extrusion machines with brakes for regulating back pressure

A technology of extrusion equipment and braking device, used in transportation and packaging, thin material handling, household appliances, etc., can solve the problem that PU rollers cannot withstand thermal and mechanical loads, damage plastic blanks, etc., to achieve fast and accurate. The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

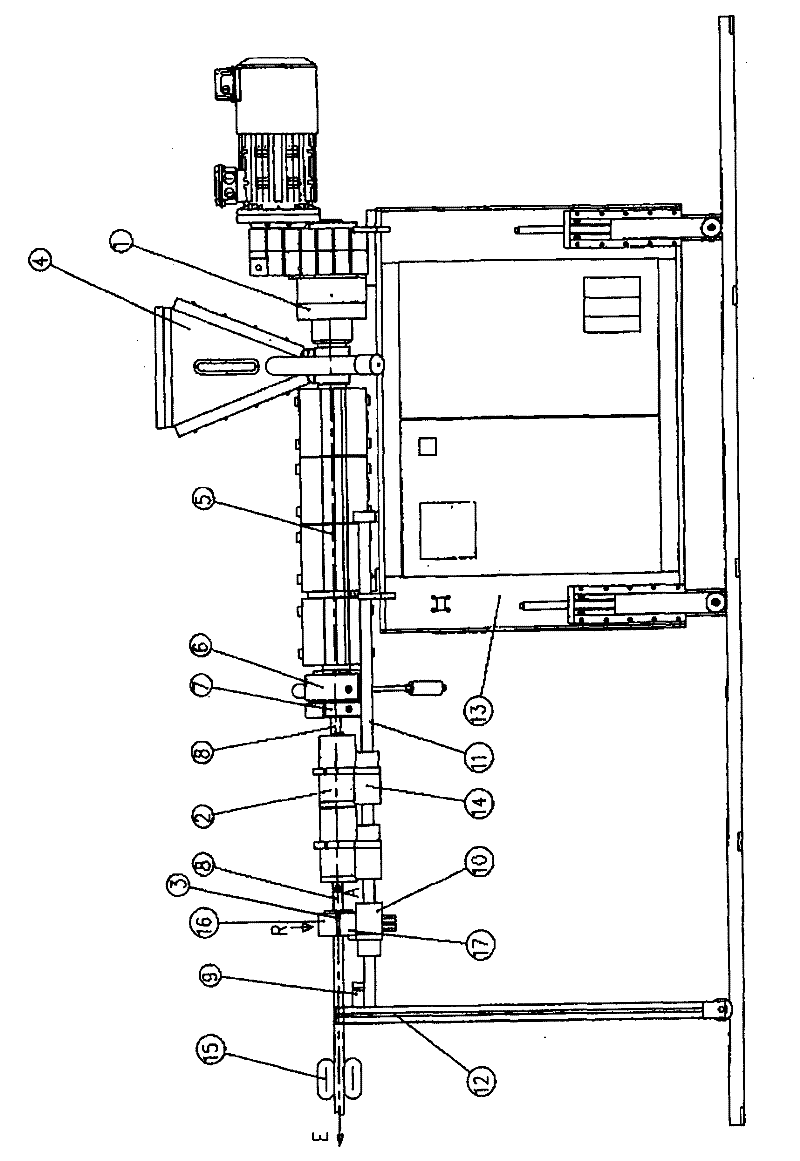

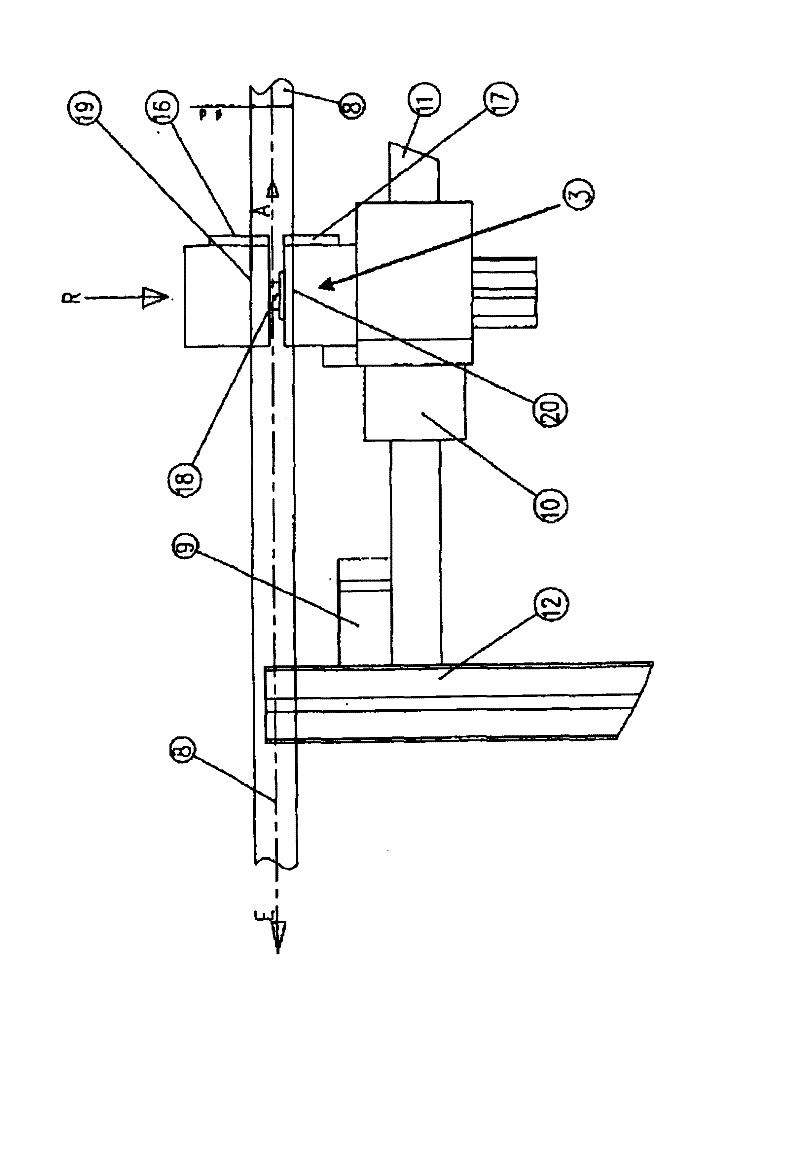

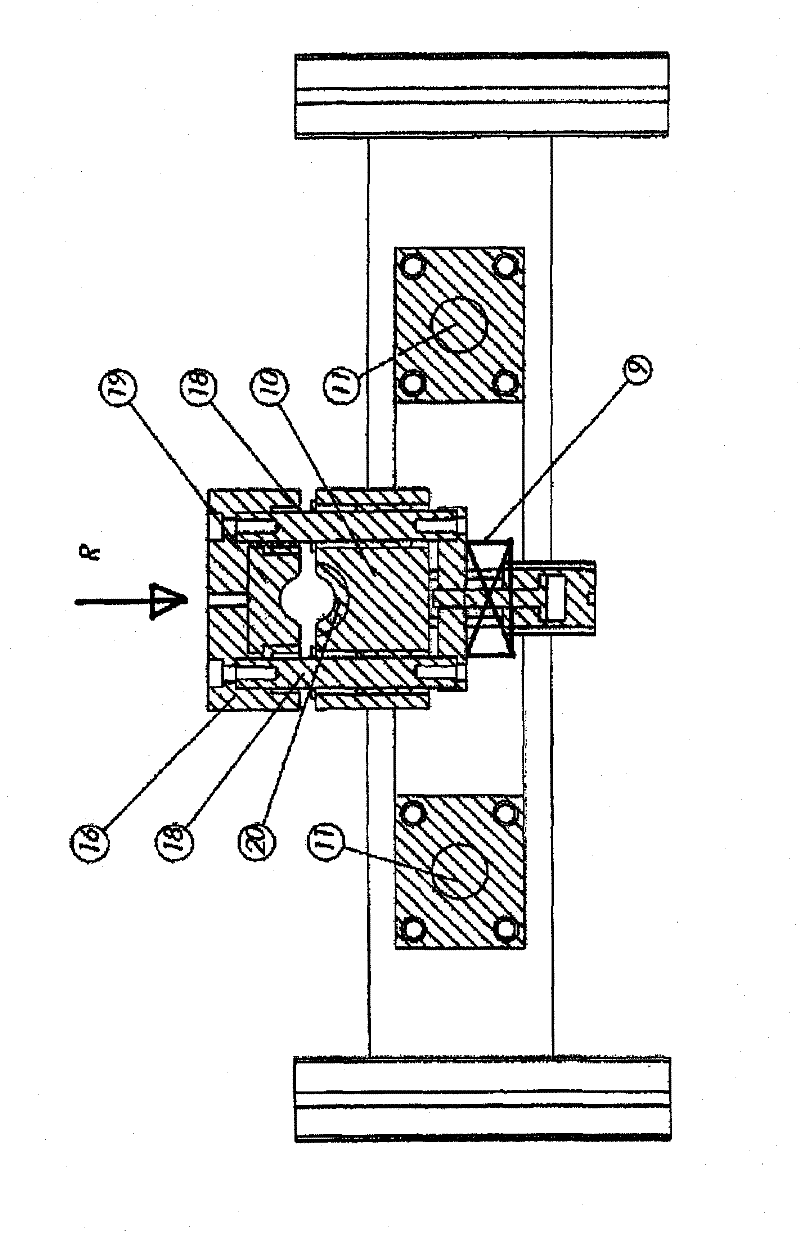

[0029] for figure 1 : The extrusion plant according to the invention further comprises an extrusion machine 1 , a correction element 2 and a braking device 3 . These components are arranged coaxially along the linear extrusion direction E. The extruder 1 is a screw extruder, a machine known in the processing of thermoplastics. The extruder contains thermoplastic raw material in the form of pellets in the hopper 4 . Arranged in the extruder 1 is a screw 5 surrounded by a heating section, which conveys the pellets under the action of heat in the extrusion direction E and applies pressure to the pellets. Downstream of the screw 5 there is an accumulation chamber 6 in which the plastic is present as a melt under pressure. In this case, the temperature when extruding the highly heat-resistant thermoplastic polyether ether ketone is approximately 400° C., and the optimum back pressure when extruding a solid PEEK rod is approximately 5 bar.

[0030] Downstream, an accumulation cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com