Hydraulic hammer

A hydraulic hammer and pressure technology, applied in the field of hydraulic impact mechanism, can solve problems such as structural complexity, high cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

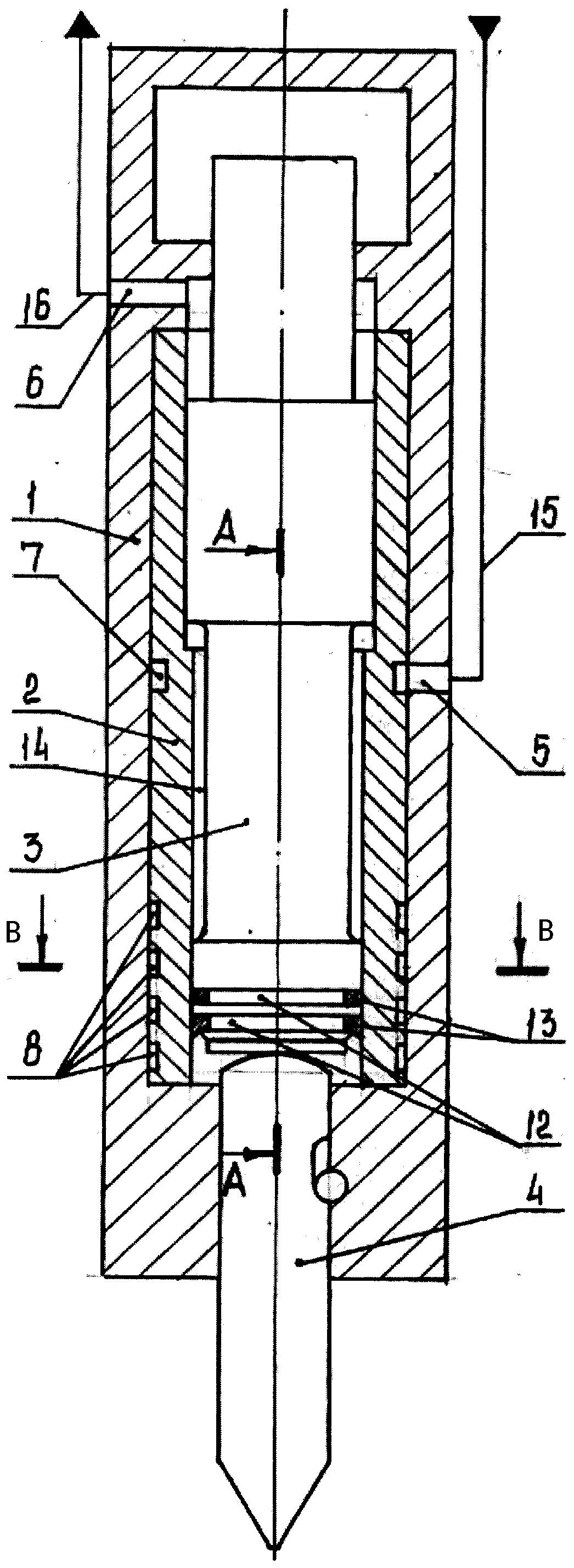

[0029] The hydraulic hammer includes a casing 1 , a sleeve 2 , a hammer head 3 and a work piece 4 .

[0030] Pressure holes 5 and relief holes 6 are made on the casing 1 .

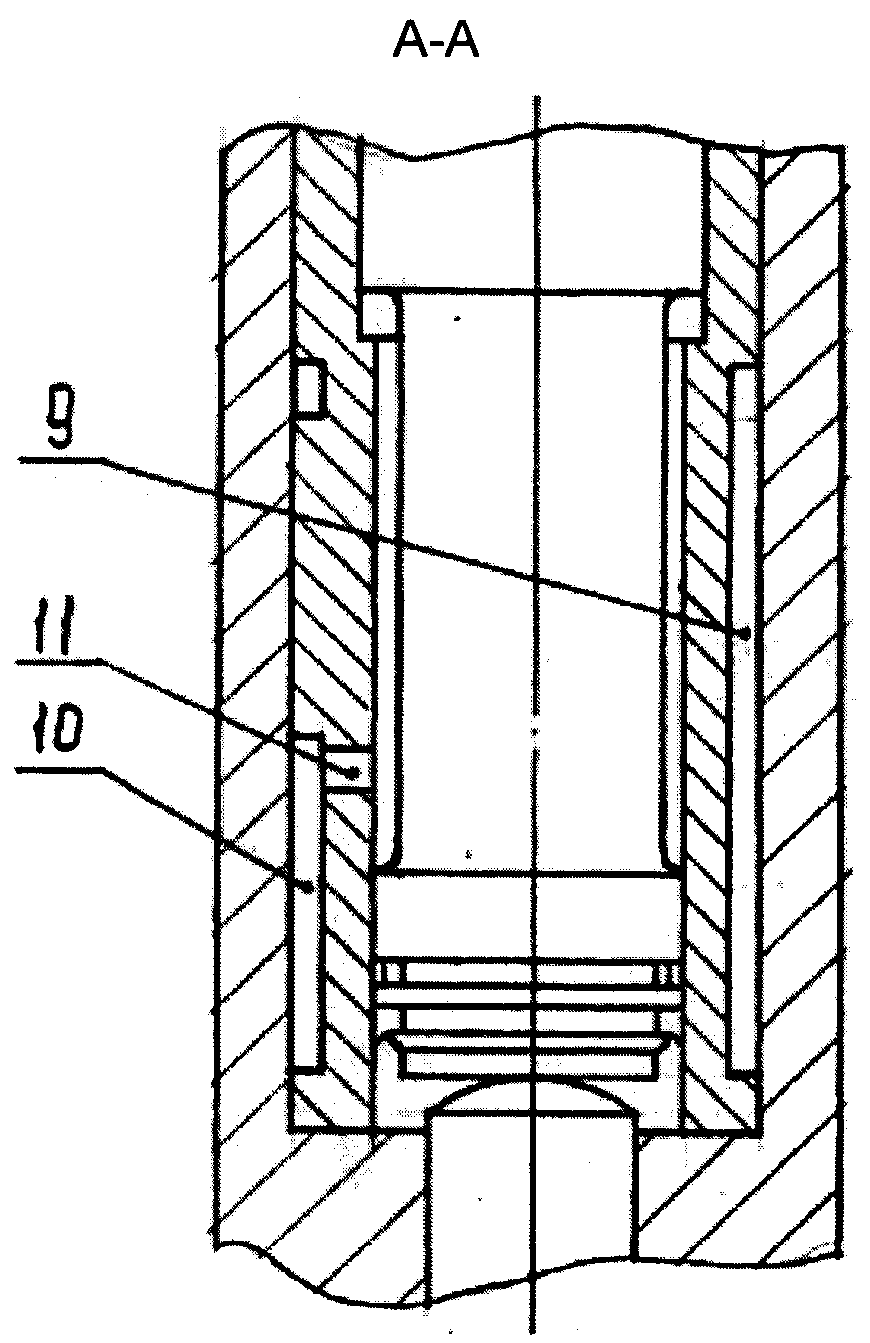

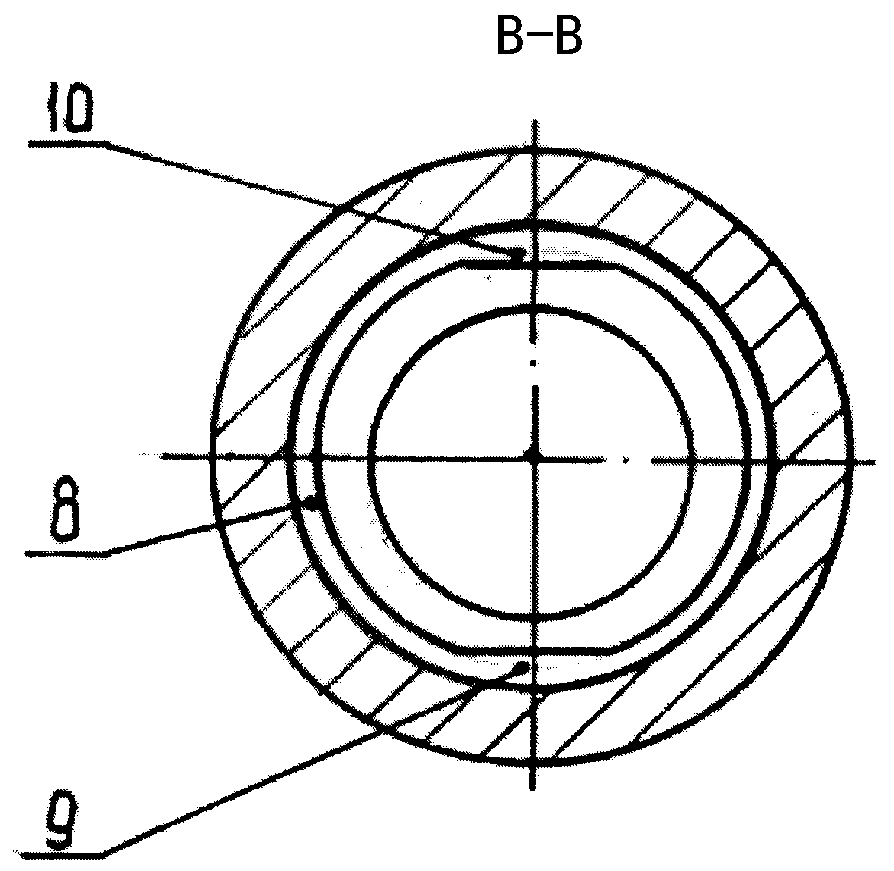

[0031] On the outer surface of the sleeve 2 there are pressure cutouts 7 , a plurality of cutouts 8 and diametrically opposite first longitudinal grooves 9 and second longitudinal grooves 10 . The sleeve wall has pressure holes 11 connected to this longitudinal groove 10 .

[0032] At the lower part of the hammer head 3 there are a plurality of annular grooves 12 in which seals 13 are installed.

[0033] The sleeve 2 is installed in the casing 1 . The hammer head 3 is arranged in the sleeve 2, the pendant head reciprocates therein and forms a firing cavity 14 therewith.

[0034] The pressure hole 5 is connected to a pressure line 15 , and the discharge hole 6 is connected to a discharge line 16 .

[0035] The work piece 4 is mounted on the bottom of the hydraulic hammer.

[0036] During operation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com