Method for improving coal quality through multi-layer roaster

A multi-layer roaster and coal technology, which is applied in the field of coal coking, can solve the problems of long process time and waste of coal resources, and achieve the effect of low process requirements, high production efficiency and guaranteed contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Using coal from a certain area in Xinjiang, the technical indicators are as follows:

[0047] Particle size: <20mm;

[0048] Total moisture (MT): 18-22%;

[0049] Ash content (Ad): 8-10%;

[0050] Volatile matter (Vad): 40-45%;

[0051] Calorific value (Qgr): 4000~5000kcal / kg;

[0052] Viscosity (R.I): <10;

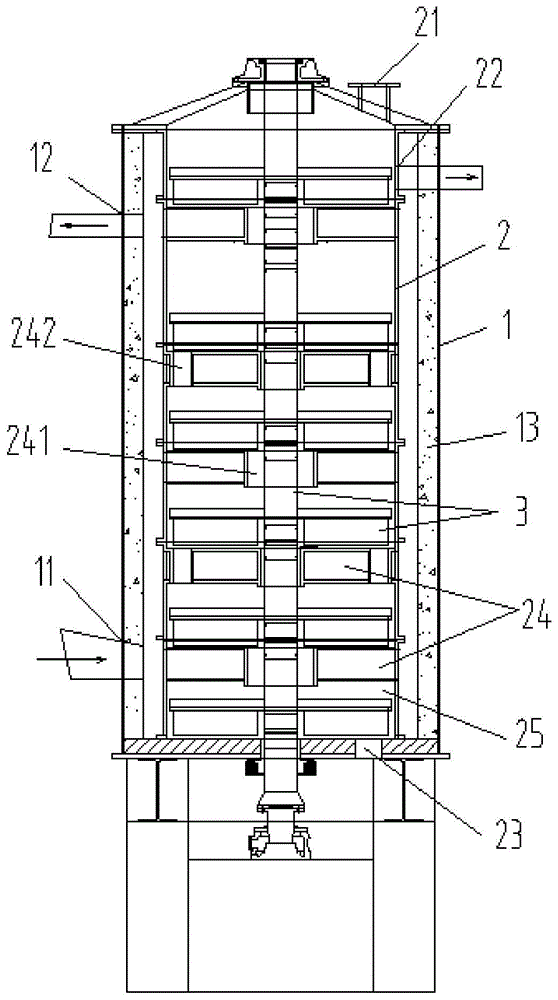

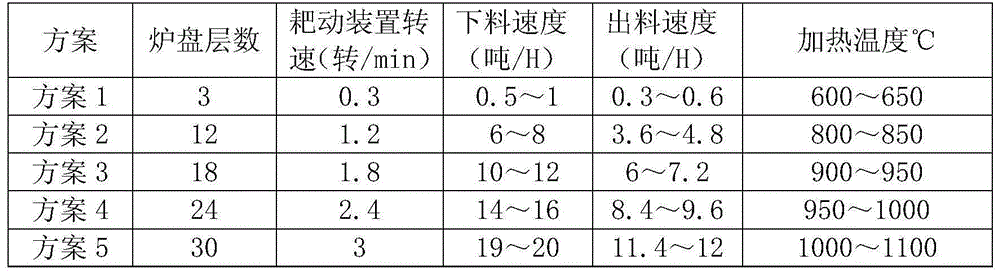

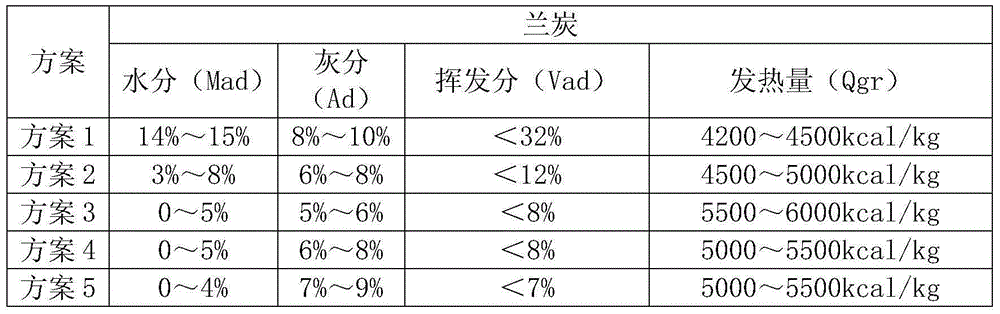

[0053] The scheme of the present invention that adopts is: adopt multi-layer roasting furnace, multi-layer roasting furnace comprises outer furnace body 1 with heating device, is provided with heating furnace 2 in outer furnace body 1, and heating furnace 2 top is provided with feed inlet 21, coal gas A collection port 22, a discharge port 23 is provided at the bottom of the heating furnace 2, and at least 3 layers of furnace plates 24 are arranged at intervals along the height direction in the heating furnace 2, and the furnace plate 24 of the Nth layer has a middle feeding hole 241, and the N+1 layer The furnace tray 24 has an end feeding hole 242, forming a...

Embodiment 2

[0066] The furnace tray 24 adopts the alloy steel materials shown in Table 4, all of which can well meet the working conditions of the present invention.

[0067] Table 4 alloy steel composition

[0068]

Embodiment 3

[0070] Table 5 Comparison table between the present invention and internal heating type vertical square furnace quality improvement process

[0071]

[0072] It can be seen from the comparison in Table 5 that:

[0073] The raw material requirement of the traditional internal heating vertical square furnace upgrading process is higher than that of the present invention, and its production cost is relatively high, resource utilization rate is relatively low and production efficiency is low.

[0074] The quality of the semi-coke produced by the upgrading process of the internal heating type vertical square furnace is lower than that of the present invention, and the semi-coke produced by the present invention can replace part of anthracite as a fuel for blast furnace injection in the iron and steel industry; as a reducing agent for metallurgical industry; activation Washing process produces activated carbon or adsorbent, which is used for the treatment of waste water and waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com