Quaternary hybrid magnetic sewage purification material and preparation method thereof

A technology for sewage purification and magnetic composite materials, which is applied in the field of nanomaterials to achieve the effect of enhanced photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

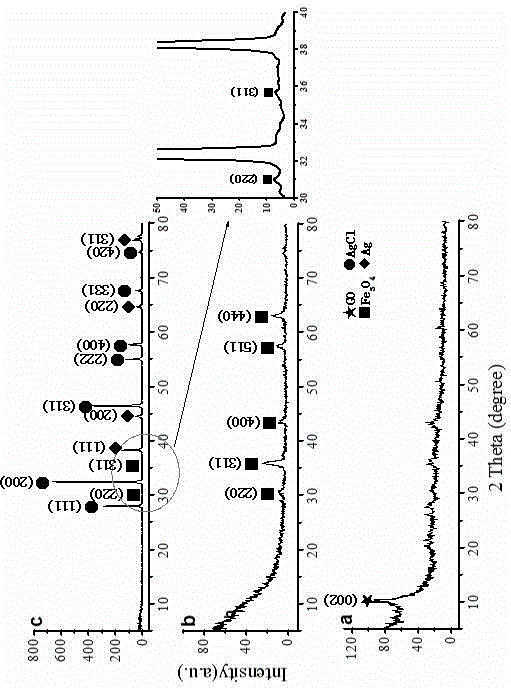

Image

Examples

Embodiment 1

[0021] Dissolve 50mg of graphene oxide in 25mL of ethylene glycol, and obtain a graphene oxide (GO) dispersion after ultrasonication for 2 hours, then weigh 0.9mmol of FeCl 3 ·6H 2 O was dissolved in the above GO dispersion and stirred for 2 h, then 1.8 g of NaAc and 0.5 g of polyethylene glycol were added, and stirred for another 30 min. Transfer the above solution to an autoclave, put it in an oven to react at 200°C for 16 hours, centrifuge after the reaction, wash the obtained product with ethanol, and put it into an oven at 50°C for drying after several cycles. Wash several times with water, magnetically separate, and add the final product into 50 mL of secondary water to form a suspension, which is ready for use.

[0022] Take 1.5mL of the above ultrasonic suspension and add it to 50mL containing 1.2mmol AgNO 3 and 2.3mL, 25wt% NH 3 . h 2 O aqueous solution; after stirring for 30min, add 1.5mL of 0.1M HCl, and vigorously stir for 24h to form a suspension solution...

Embodiment 2

[0024]Dissolve 50mg of graphene oxide in 25mL of ethylene glycol, and obtain a graphene oxide (GO) dispersion after ultrasonication for 2 hours, then weigh 0.6mmol of FeCl 3 ·6H 2 O and 0.3 mmol MnCl 2 4H 2 O was dissolved in the above GO dispersion and stirred for 2 h, then 1.8 g of NaAc and 0.5 g of polyethylene glycol were added, and stirred for another 30 min. Transfer the above solution to an autoclave, put it in an oven to react at 200°C for 16 hours, centrifuge after the reaction, wash the obtained product with ethanol, and put it into an oven at 50°C for drying after several cycles. Wash several times with water, magnetically separate, and add the final product into 50 mL of secondary water to form a suspension, which is ready for use.

[0025] Take 3mL of the above-mentioned sonicated suspension and add it to 50mL containing 1.2mmol AgNO 3 and 2.3mL, 25wt% NH 3 . h 2 O aqueous solution, after stirring for 30 min, add 1.5 mL of 0.1 M HBr, and vigorously stir...

Embodiment 3

[0027] Dissolve 50mg of graphene oxide in 25mL of ethylene glycol, and obtain a graphene oxide (GO) dispersion after ultrasonication for 2 hours, then weigh 0.6mmol of FeCl 3 ·6H 2 O and 0.3 mmol ZnCl 2 ·6H 2 O was dissolved in the above GO dispersion and stirred for 2 h, then 1.8 g of NaAc and 0.5 g of polyethylene glycol were added, and stirred for another 30 min. Transfer the above solution to an autoclave, put it in an oven to react at 200°C for 16 hours, centrifuge after the reaction, wash the obtained product with ethanol, and put it into an oven at 50°C for drying after several cycles. Wash several times with water, magnetically separate, and add the final product into 50 mL of secondary water to form a suspension, which is ready for use.

[0028] Take the 6mL solution of the above-mentioned ultrasonic suspension and add it to 50mL containing 0.6mmol Ag 2 MoO 4 and 2.3mL, 25wt% NH 3 . h 2 O aqueous solution; after stirring for 30min, add 1.5mL of KI, and vig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com