Raman strengthening active microsphere and preparation method and application thereof

A technology to enhance activity, microspheres, applied in the fields of microsphere preparation, Raman scattering, microcapsule preparation, etc., can solve the problem of low reproducibility and instability of Raman signals, cannot be differentiated and located one by one, "hot spots" Uneven distribution and other problems, to achieve good application prospects, reduce low reproducibility and instability, and achieve accurate and controllable coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: prepare the MF microsphere of different sizes

[0018] 1.1 Preparation of MF microspheres with MF size of 0.4 μm

[0019] Melamine 0.625g, formaldehyde 0.9g, used for alkali adjustment solution pH = 11, pre-polymerized at 100°C for 0.5 hours, then adjusted the pH to 4, reacted for 2 hours, left to stand, removed the upper emulsion, the obtained product was mixed with ethanol and The product was washed three times with water, and the product was separated. Finally, the product was vacuum-dried at 50°C to obtain MF microspheres with a particle size of about 0.4 μm.

[0020] 1.2 Preparation of MF microspheres with MF size of 1 μm

[0021] The procedure was the same as that described in Example 1.1, except that the reaction temperature was changed from 100 °C to 70 °C, and the amount of acid was 50 μL.

[0022] 1.3 Preparation of MF microspheres with MF size of 3 μm

[0023] The procedure was the same as that described in Example 1.1, except that the reacti...

Embodiment 2

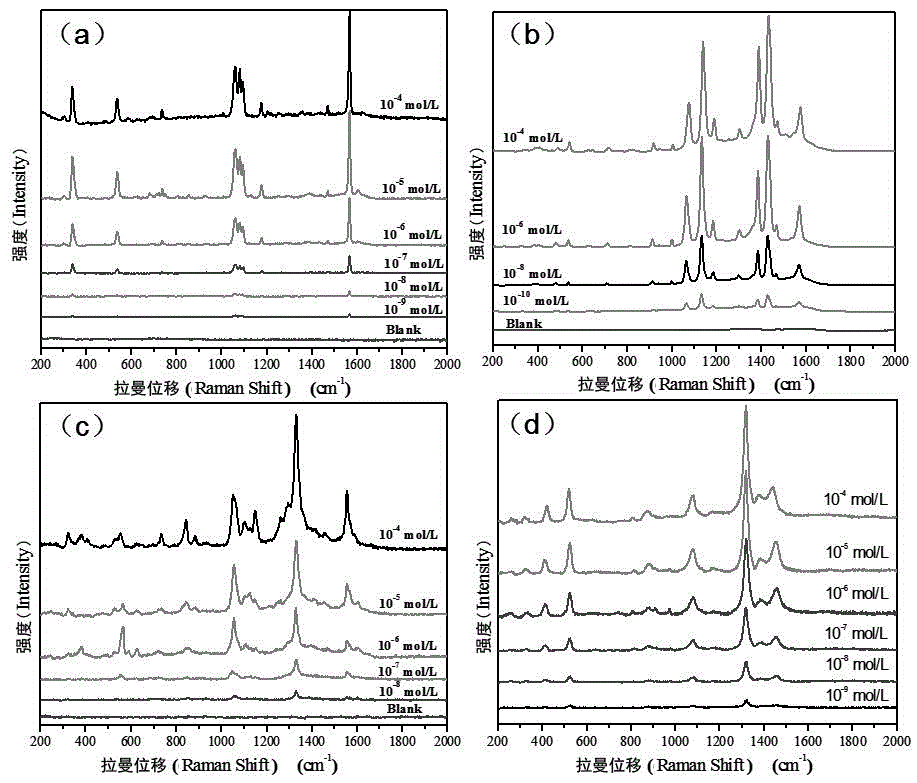

[0026] Example 2: Preparation of MF / Ag-NPs composite microspheres and their application to detect 4-CBT at different concentrations.

[0027] The preparation of MF microspheres was the same as in Example 1.2, except that the amount of acid used was 7 μL. Add 10-200 mg of MF microspheres, 20-600 mg of silver nitrate, 10-300 mg of reducing agent and 10-200 mL of absolute ethanol into a centrifuge tube, and react in a shaker for 0.5-4 hours; after the reaction , centrifuged to obtain the product, and washed with absolute ethanol to obtain MF / Ag-NPs composite microspheres. Take 10mg MF / Ag-NPs microspheres and 5mL different concentrations (0~10 -9 Add the PCP solution of M) into a centrifuge tube and put it into a shaker for adsorption for 1h. The SERS signal of the sample was then detected using a Raman spectrometer.

Embodiment 3

[0028] Example 3: Preparation of MF / Ag-NPs composite microspheres and their application to detect different concentrations of 4-ABT.

[0029] The steps are the same as described in Example 2, except that the detection substance is changed from 4-CBT to 4-ABT, and the concentration is changed from 0 to 10 -9 M becomes 0~10 -10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com