Silicon detector structure with wide spectral response range and production method thereof

A fabrication method and detector technology, which are used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of severe Auger recombination in heavily doped surface layers, low mobility of black silicon materials, and high infrared light transmittance. and other problems, to achieve the effects of broadening the spectral response range, offsetting low mobility, and offsetting short carrier lifetimes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

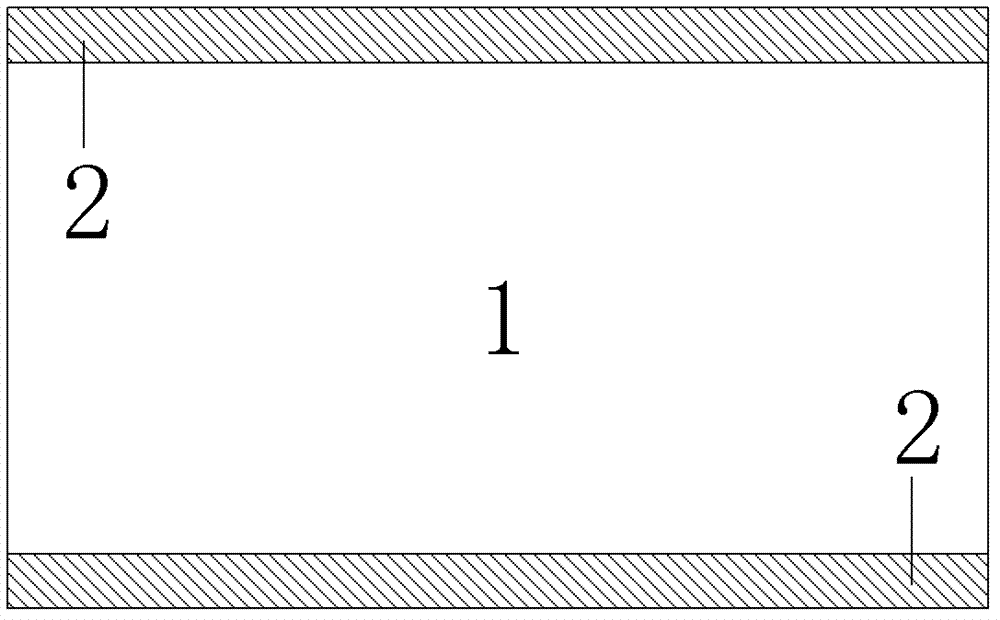

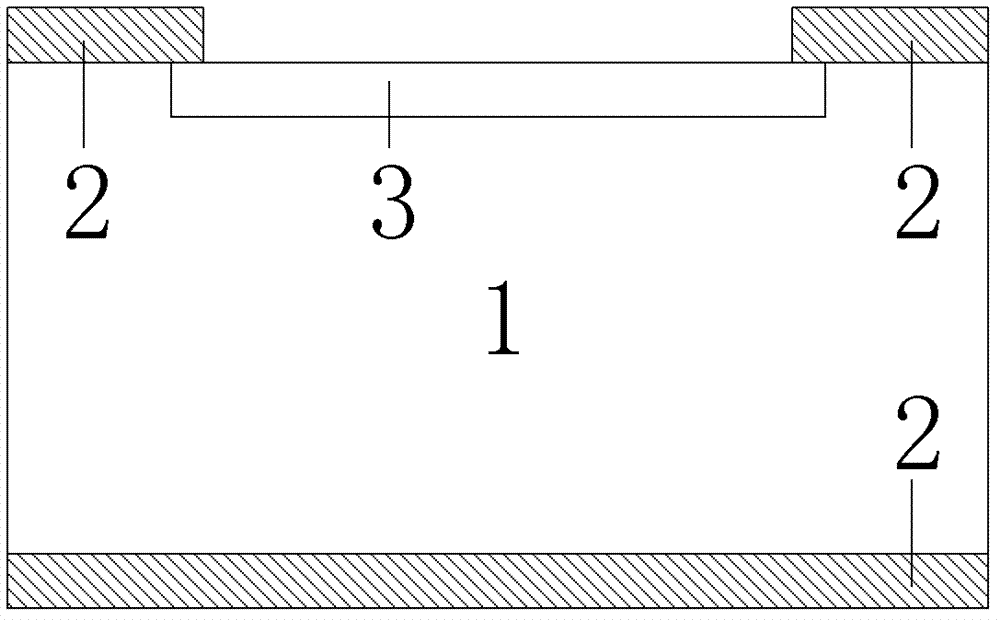

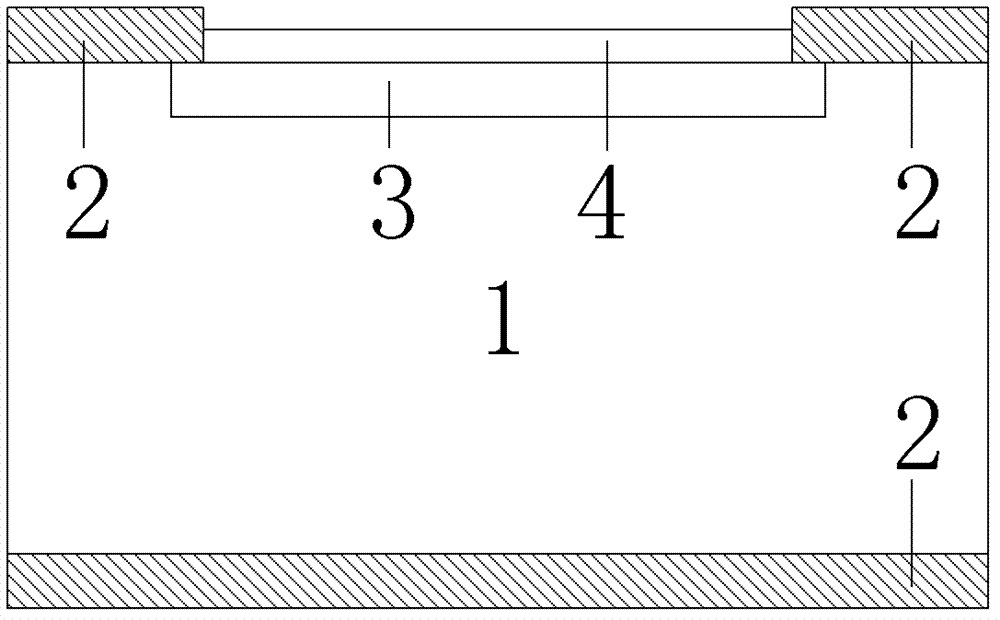

[0031] see Figure 1g , the present invention provides a silicon detector structure with wide spectral response, the structure includes from top to bottom:

[0032] An n-type silicon-based substrate layer 1 with a circular groove on the surface; the n-type silicon-based substrate layer 1 is made of n-type (111) single crystal silicon, with a thickness of 100 to 500 μm and a resistivity of 1 to 1000 Ω·cm;

[0033] A silicon dioxide dielectric masking layer 2, formed on the periphery of the circular groove on the surface of the n-type silicon-based substrate layer 1, with a ring structure in the middle;

[0034] A p-type doped layer 3 is located in the circular groove of the n-type silicon-based substrate layer 1; the p-type doped layer 3 is formed by boron ion implantation or boron diffusion on the surface of the n-type silicon-based substrate layer 1 , the p-type doped layer 3 forms a pn junction photosensitive region with the n-type silicon-based substrate layer 1;

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com