Supercapacitor slurry preparation method

A supercapacitor and slurry technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of low consistency of monomer capacitors, time-consuming preparation methods, and difficulty in mixing materials evenly, so as to reduce the scrap of pole pieces and promote electrode The performance of the performance, the effect of improving the uniformity of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] 1. Weighing of raw materials: according to the mass ratio of materials used in the conventional process, weigh the corresponding materials for use, Akg of deionized water, Bkg of binder, Ckg of conductive agent, Dkg of organic solvent, and Ekg of active material.

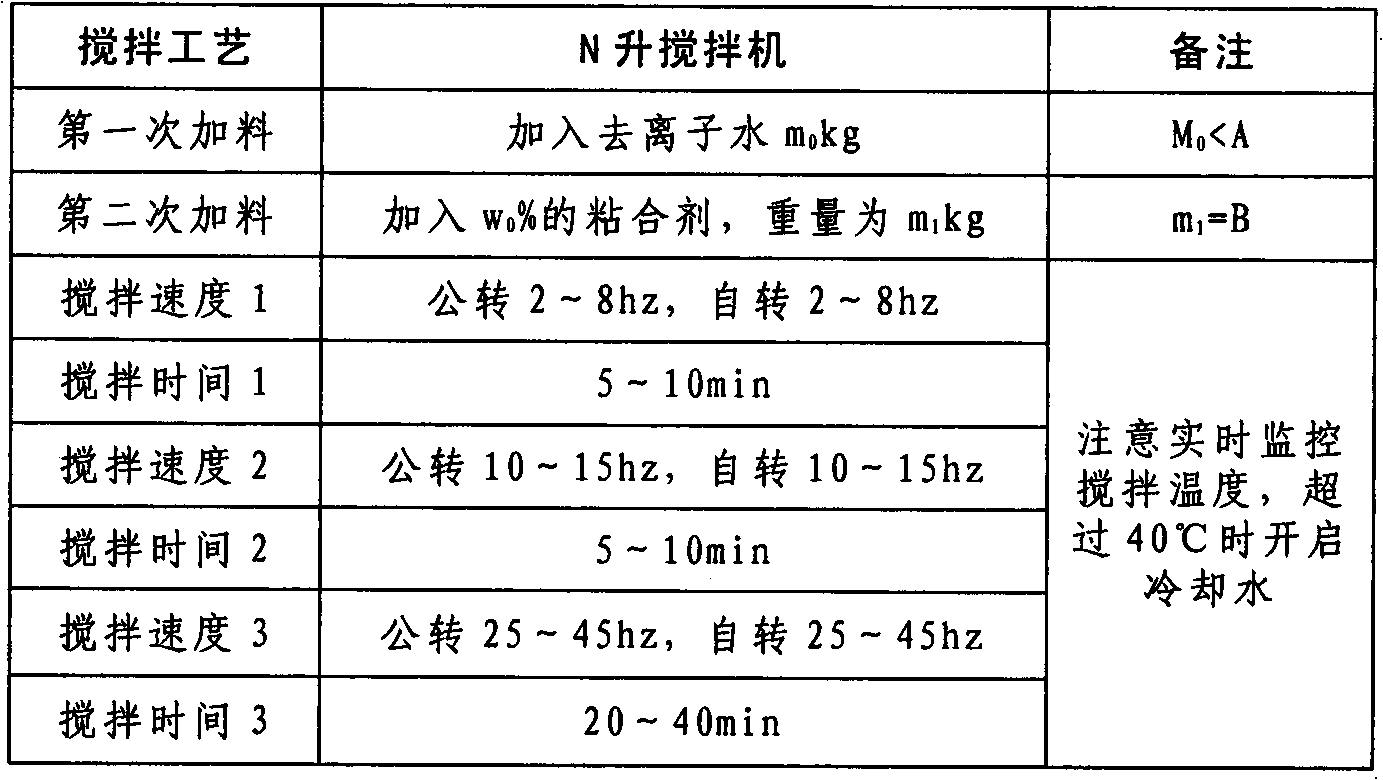

[0010] 2. Preparation of binder:

[0011] The specific process is as follows:

[0012]

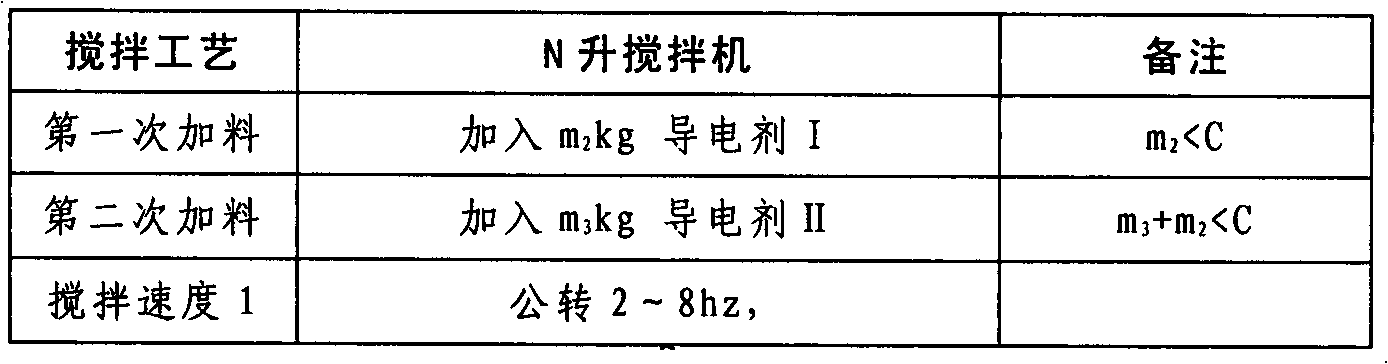

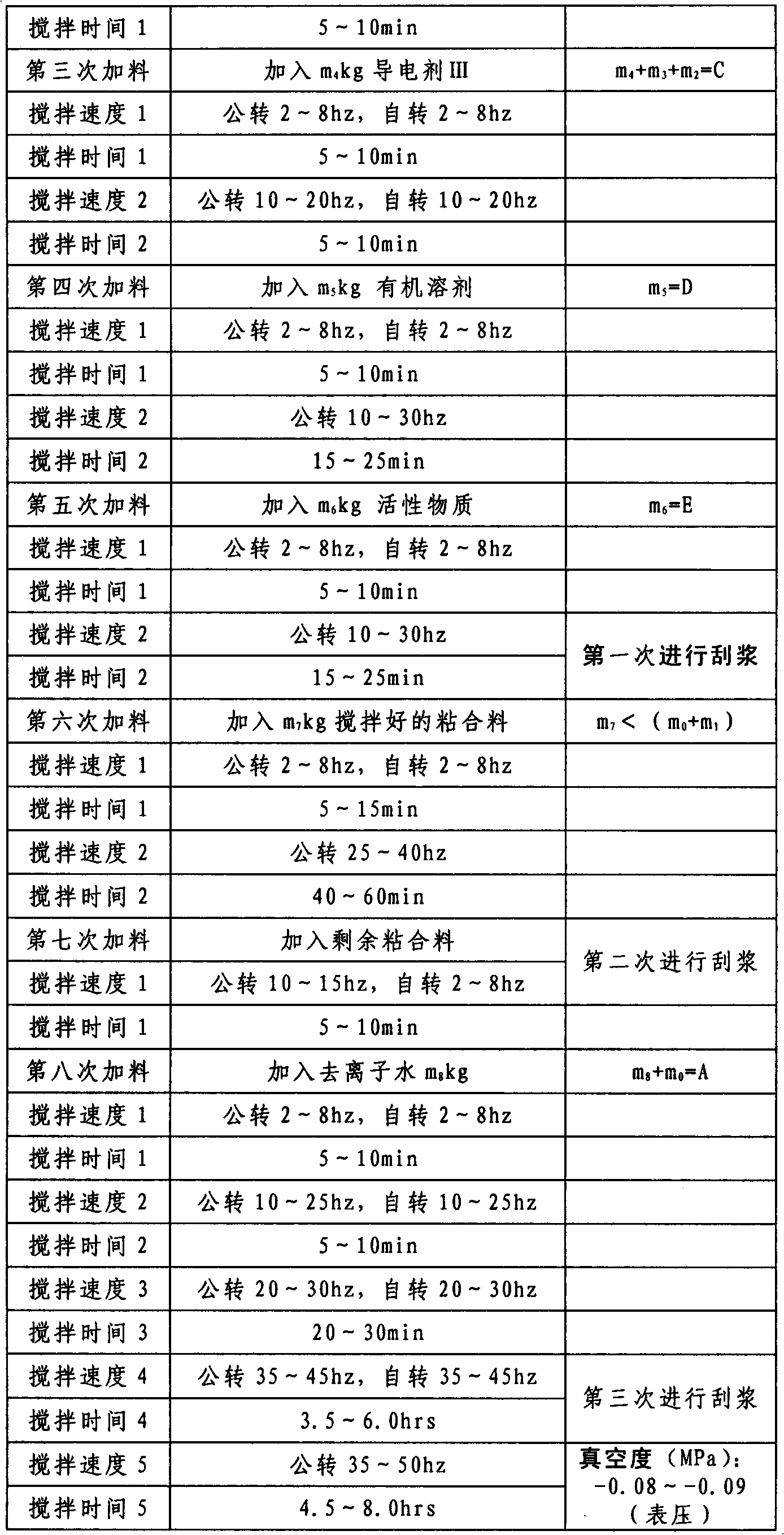

[0013] 3. Slurry preparation:

[0014] The specific process is as follows:

[0015]

[0016]

[0017] 4. Discharge: Take a sample to test the viscosity and solid content of the slurry, and adjust to the target value.

Embodiment 2

[0019] 1. Weighing of raw materials: according to the mass ratio of materials used in the conventional process, weigh the corresponding materials for use, Akg of deionized water, Bkg of binder, Ckg of conductive agent, Dkg of organic solvent, and Ekg of active material.

[0020] 2. Preparation of binder:

[0021] The specific process is as follows:

[0022]

[0023] 3. Slurry preparation:

[0024] The specific process is as follows:

[0025]

[0026]

[0027] 4. Discharge: Take a sample to test the viscosity and solid content of the slurry, and adjust to the target value.

Embodiment 3

[0029] 1. Weighing of raw materials: According to the mass ratio of materials used in the conventional process, weigh the corresponding materials for use. Deionized water Akg, binder Bkg, conductive agent Ckg, organic solvent Dkg, active material Ekg.

[0030] 2. Preparation of binder:

[0031] The specific process is as follows:

[0032]

[0033] 3. Slurry preparation:

[0034] The specific process is as follows:

[0035]

[0036]

[0037] 4. Discharge: Take a sample to test the viscosity and solid content of the slurry, and adjust to the target value.

[0038] In the above embodiments, Example 1 and Example 2 are a dry-mixed wet-mixed method, and Example 3 is a wet-mixed method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com