A kind of high plasticity high tenacity super high strength steel plate and its production method

A technology of ultra-high strength and production methods, which is used in temperature control, heat treatment equipment, heat treatment process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

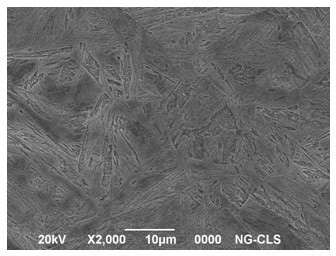

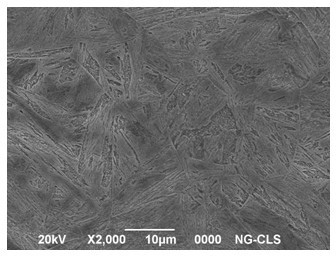

Image

Examples

Embodiment Construction

[0037] A high-plasticity, high-toughness and ultra-high-strength steel plate according to the present invention, the chemical composition of the steel in the steel plate is calculated by weight percentage, C: 0.14-0.18%, Si: 0.10-0.30%, Mn: 0.80-1.30%, P: ≤0.015%, S: ≤0.005%, Nb: 0.010~0.050%, Ti: 0.006~0.020%, V: 0.020~0.060%, Cr: 0.30~0.60%, Mo: 0.20~0.80%, and the balance is Fe and unavoidable impurities.

[0038] According to the production process of the present invention, the actual chemical composition of the smelting and rolling steel of the present invention is shown in Table 1.

[0039] Table 1 Chemical composition (wt%) of the embodiment of the present invention

[0040] Example C Si mn P S Nb V Ti Cr Mo Example 1 0. 17 0.20 0.9 0.010 0.0008 0.045 0.045 0.010 0.40 0.55 Example 2 0. 14 0.25 1.2 0.013 0.0007 0.044 0.051 0.012 0.50 0.60 Example 3 0.18 0.25 1.1 0.010 0.0010 0.025 0.025 0.008 0.55 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com