High-temperature, water-resistant, long-life complex lithium-calcium-based lubricating grease and preparation method thereof

A calcium-based grease, long-life technology, applied in the field of grease, can solve the problems of less complex lithium-based grease, short grease soap fibers, weak ability of fibers to agglomerate into grease, etc., to achieve water resistance and extreme pressure resistance. The effect of improving grinding capacity, saving energy consumption and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

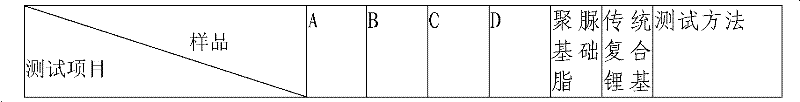

[0023] Add 300g (parts by mass of 15.1%) 12 hydroxystearic acid and 61g (parts by mass of 3.1%) salicylic acid into 1600g (parts by mass of 80.4%) base oil, mix and heat to 60~90℃ , Adding 28g (1.4% by mass) of boric acid and 70g of monohydrate lithium hydroxide saponification compound for 1.5 to 2 hours; heating up to 185 to 190°C in 2 hours, and the temperature is kept constant for 1.5 hours; continue heating to 220 to 240°C, Then the desired product can be obtained by natural cooling. Sample number A.

Embodiment 2

[0025] 300g (parts by mass is 14.5%) 12 hydroxystearic acid, 61g (parts by mass is 2.9%) salicylic acid, and 80g (parts by mass is 3.9%) calcium alkyl benzenesulfonate with high base value are added to 1600g (77.3% by mass) base oil, mix and heat to 60~90℃, add 28g (1.4% by mass) boric acid and 63.5g monohydrate lithium hydroxide saponification compound for 1.5~2 hours; use 2 hours to heat up When it reaches 185~190℃, the temperature is kept constant for 1.5 hours; continue to heat up to 220~240℃, and then naturally cool down to obtain the desired product. Sample number B. From the analysis data in Table 1, it can be seen that the bearing life of sample B is significantly longer than that of sample A and traditional lithium complex base grease after adding calcium alkyl benzene sulfonate with high base value. The roller test shows that sample A and traditional The lithium complex base grease is completely emulsified in contact with water, and the micro cones soften about 30, w...

Embodiment 3

[0027] 300g (parts by mass is 14.5%) 12 hydroxystearic acid, 61g (parts by mass is 2.9%) salicylic acid, and 80g (parts by mass is 3.9%) calcium alkyl benzenesulfonate with high base value are added to 1600g (77.3% by mass) base oil, mix and heat to 60~90℃, add 28g (1.4% by mass) boric acid, 63.5g lithium hydroxide monohydrate and 18.6g calcium hydroxide saponification compound 1.5~2 Hours; It takes 2 hours to heat up to 185~190℃, the temperature is kept constant for 1.5 hours; continue to heat up to 220~240℃, and then naturally cool down to obtain the desired product. Sample number C. After adding calcium hydroxide on the basis of the formulation process of sample B, it can be seen from Table 1 that the drop point of the prepared sample is greatly improved, while other bearing life and drum test performance have little change.

[0028] (The molar amount of 12 hydroxystearic acid: the molar amount of salicylic acid: the molar amount of boric acid = 1:0.44:0.45; lithium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com