A kind of synthetic method of broad-spectrum antibiotic chloramphenicol

A synthesis method and technology of chloramphenicol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of long synthesis route of chloramphenicol, production cost and increase of three wastes, etc., to solve the problems of three wastes, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

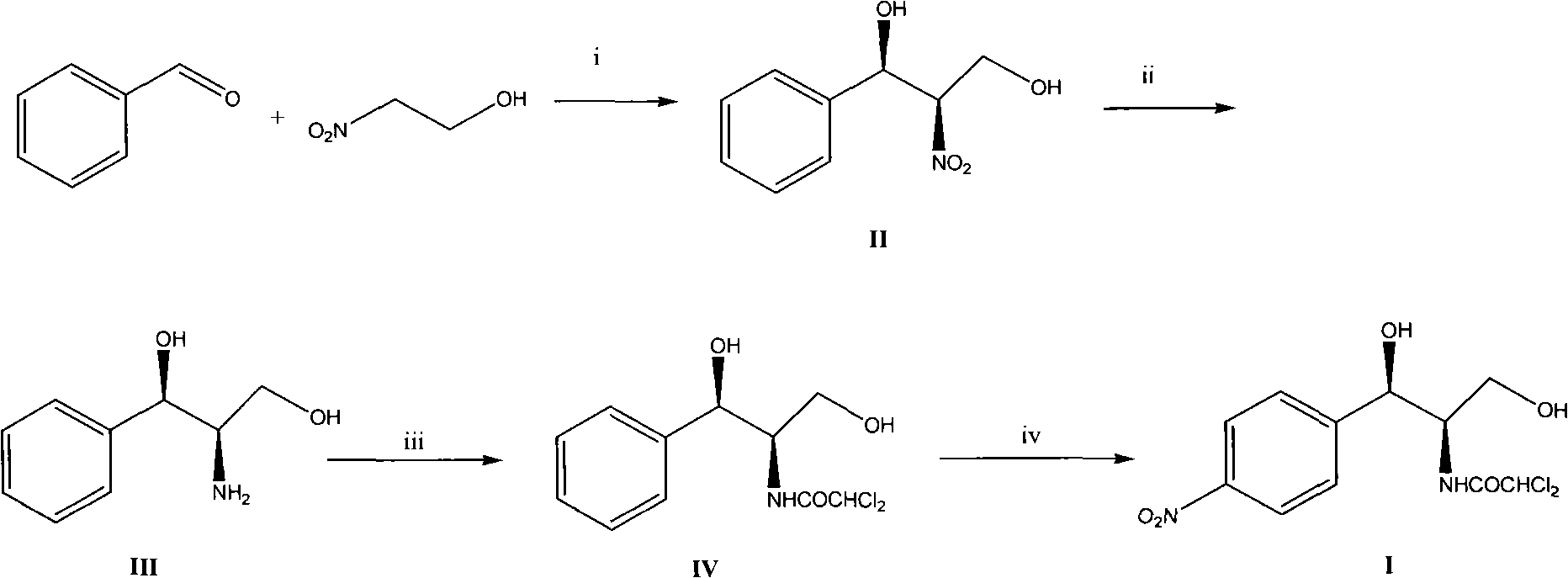

[0028] Embodiment 1 (1R, 2R)-2-nitro-1-phenyl-1, the preparation of 3-propanediol

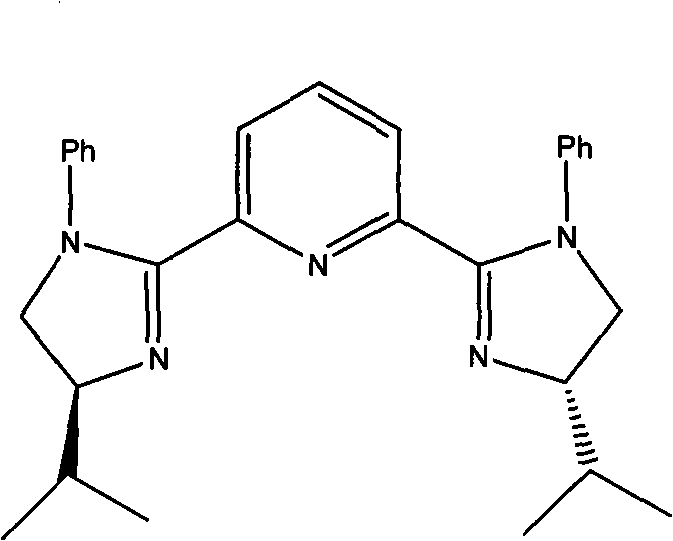

[0029] 0.9 g of Cu(OTf) 2 (0.25mmol), 1.2 grams of 2,6-bis[(S)-4-isopropyl-1-phenyl-4,5-dihydro-1H-2-imidazolyl]pyridine (2.6mmol) and 20 ml Add 1,4-dioxane into a 100 ml single-necked flask, replace the air inside with nitrogen to keep the nitrogen flow constant, stir with magnetic force for 2 hours, then cool with an ice bath, add 2.7 g of benzaldehyde (25 mmol), 22.8 g of 2 -Nitroethanol (250mmol) and N-methylmorpholine (0.27 milliliters, 2.5mmol), the reaction solution was stirred in an ice-bath cooling for 24 hours, after the thin-plate chromatography detected no raw material benzaldehyde spots, then evaporated under reduced pressure to remove volatile non-toxic solvent, the catalyst was removed by silica gel filtration, and the filtrate was concentrated to obtain 4.4 grams of product, the yield was 90%, and the e.e value was 93% as determined by HPLC. 1 H NMR (acetone-d 6 )δ: 3.46(ddd,...

Embodiment 2

[0030] The preparation of embodiment 2 (1R, 2R)-2-amino-1-phenyl-1,3-propanediol

[0031] Dissolve 5 g of (1R, 2R)-2-nitro-1-phenyl-1,3-propanediol (25 mmol) in 100 ml of methanol, add 0.1 g of 10% palladium-on-carbon catalyst, under hydrogen pressure 50Psi Hydrogenation reduction, no raw material spots detected by thin-plate chromatography, and the catalyst was removed by filtration. After the filtrate was concentrated, it was recrystallized with a 1:1 ethanol-ether mixed solvent to obtain 4.0 g of the product, with a yield of 94%, m.p.111-113 ° C, other data and literature to , Y.; Masaya, S.; Hayashi, T. J. Am. Chem. Soc. 1986, 108, 6405. Concordance.

Embodiment 3

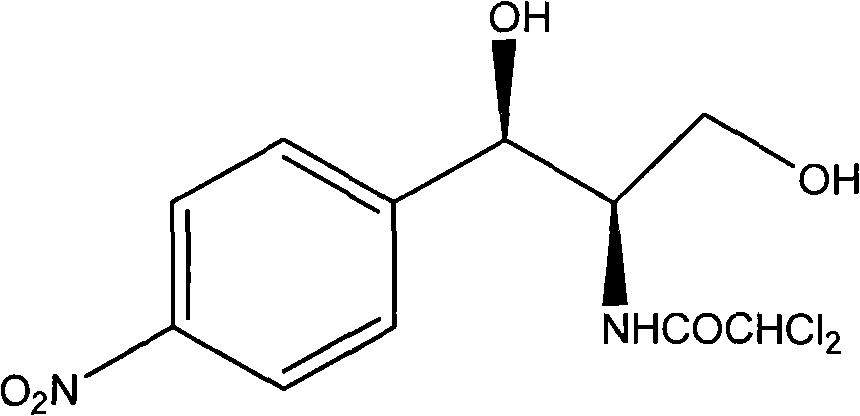

[0032] The preparation of embodiment 3 (1R, 2R)-2-dichloroacetamido-1-phenyl-1,3-propanediol

[0033] Add 4 grams of (1R, 2R)-2-amino-1-phenyl-1,3-propanediol (24mmol) and 40ml of methyl dichloroacetate (0.4mol) into a single-necked flask in turn, and stir at 100-110°C After 2 hours, thin plate chromatography detected no raw material spots, and then concentrated under reduced pressure. The solid was recrystallized from a mixed solvent of ethyl acetate and n-hexane to obtain 6.0 g of the product, with a yield of 93%, m.p.93-95°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com