Forsterite structure and thermal insulation integrated composite brick and preparation method thereof

A forsterite and composite brick technology, applied in the field of refractory materials, can solve the problems of poor thermal insulation performance, poor wear resistance, low structural strength, etc., and achieve the effects of energy saving, good wear resistance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

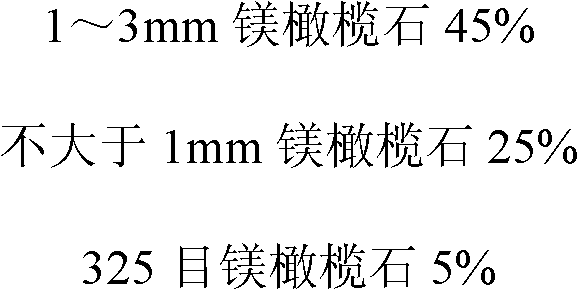

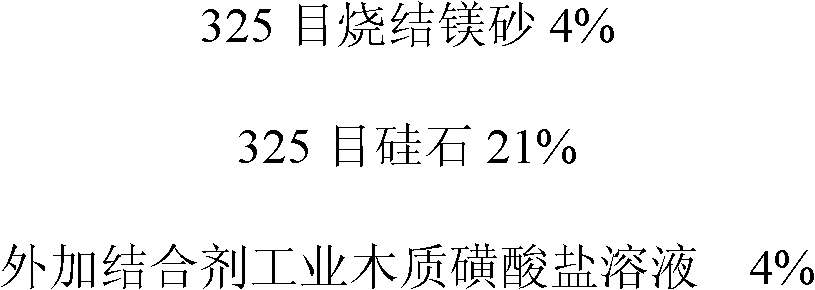

[0034] The particle gradation and mass percentage of the raw materials used in the heavy working layer in this embodiment are:

[0035]

[0036]

[0037] Among them, the raw materials used are forsterite from Yichang, Hubei, silica and sintered magnesia with grade GS-98.5.

[0038] According to the above proportioning ratio, the mass percent MgO% of the obtained heavy working layer composition is 40%, SiO 2 % is 45%, and the rest are other ingredients introduced by raw materials.

[0039] The raw materials and their mass percentages used in the lightweight heat insulation layer are: 70% of corundum hollow spheres, 30% of 325 mesh forsterite, 6% of pulp waste liquid with additional binder, among which Al 2 o 3 The composition mass percentage is 93%.

[0040] The manufacturing method of forsterite structural heat insulation integrated composite brick comprises the following steps:

[0041] (1) Ingredients:

[0042] Heavy working layer: first mix aggregate particles an...

Embodiment 2

[0047] The particle gradation and mass percentage of the raw materials used in the heavy working layer in this embodiment are:

[0048]

[0049] Among them, the raw materials used are forsterite from Yichang, Hubei, silica and fused magnesia with the grade GS-98.5.

[0050] According to the above proportioning ratio, the mass percent MgO% of the obtained heavy working layer composition is 50%, SiO 2 % is 43%, and the rest are other ingredients introduced by raw materials.

[0051] The raw materials and their mass percentages used in the lightweight heat insulation layer are: 60% corundum hollow balls, 10% lightweight mullite aggregates, 30% 325 mesh forsterite, 6% pulp waste liquid with additional binder, Al in the corundum hollow spheres used 2 o 3 The mass percentage of the component is 95%, and the mass percentage of the component in the lightweight mullite aggregate is Al 2 o 3 65%.

[0052] The manufacturing method of forsterite structural heat insulation integra...

Embodiment 3

[0059] The particle gradation and mass percentage of the raw materials used in the heavy working layer in this embodiment are:

[0060]

[0061] Among them, the raw materials used are silica and fused magnesia of forsterite in Yichang, Hubei.

[0062] According to the above proportioning ratio, the mass percent MgO% of the obtained heavy working layer composition is 51%, SiO 2 % is 30%, and the rest are other ingredients introduced by raw materials.

[0063] The raw materials and their mass percentages used in the lightweight heat insulation layer are: 40% of corundum hollow balls, 15% of lightweight high-alumina aggregates, 45% of 325-mesh forsterite, and 10% of pulp waste liquid with additional binder, of which Al in corundum hollow spheres used 2 o 3 The mass percentage of the component is 93%, and the mass percentage of the component in the lightweight high-alumina aggregate is Al 2 o 3 70%.

[0064] The manufacturing method of forsterite structural heat insulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com