Overlay welding method for small-diameter through-holes

A small aperture and aperture technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve problems such as holes, deep small holes, and cracks in the surfacing layer, so as to ensure quality and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the surfacing welding method for small-diameter through-holes provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

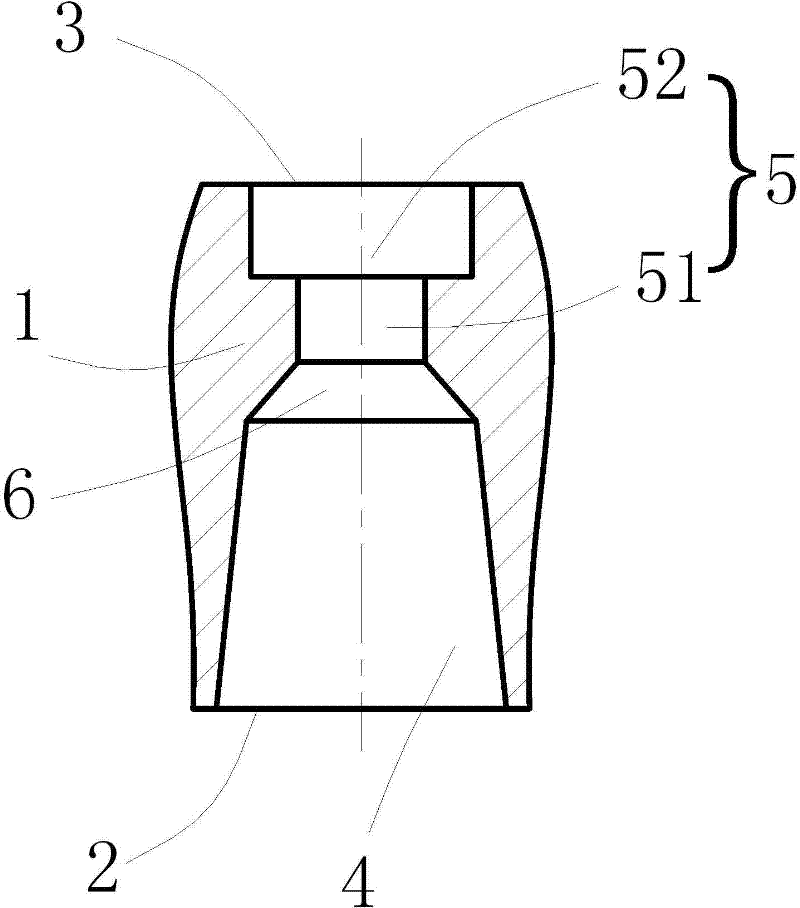

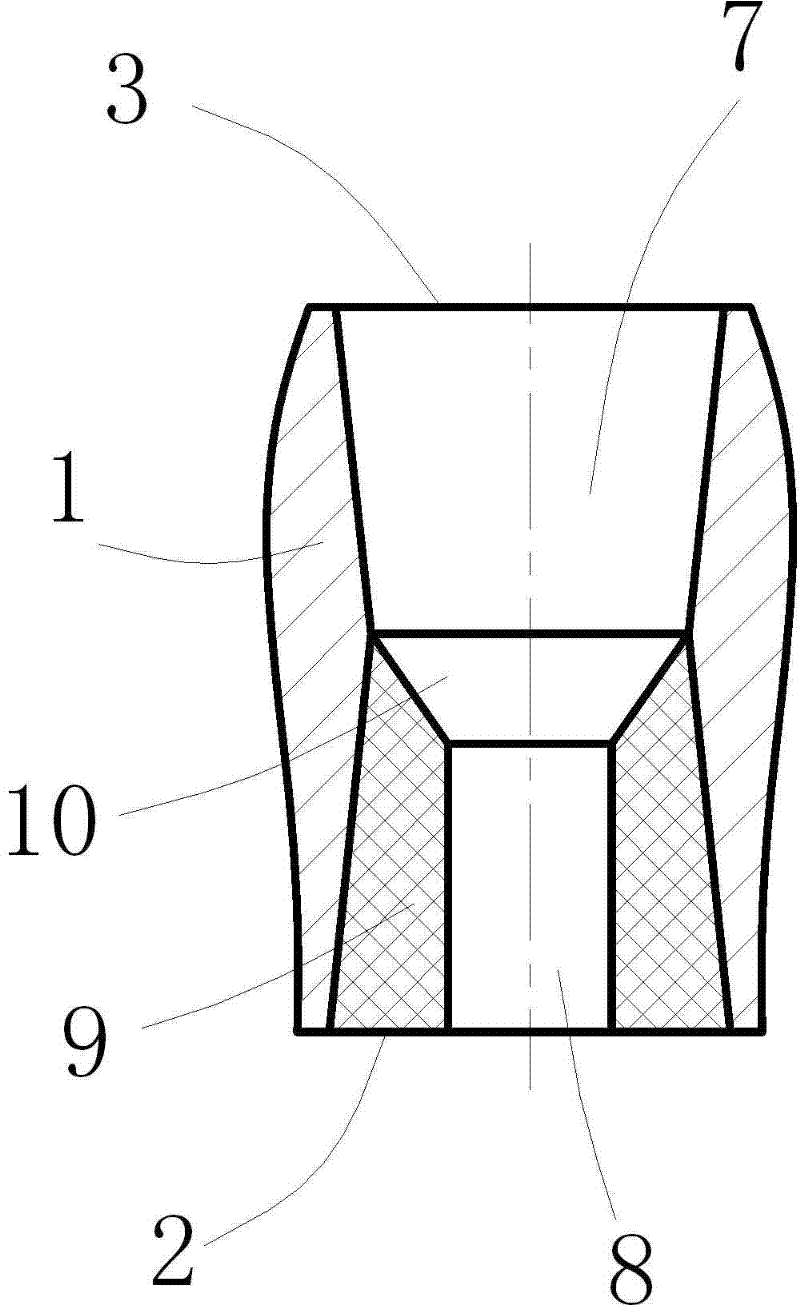

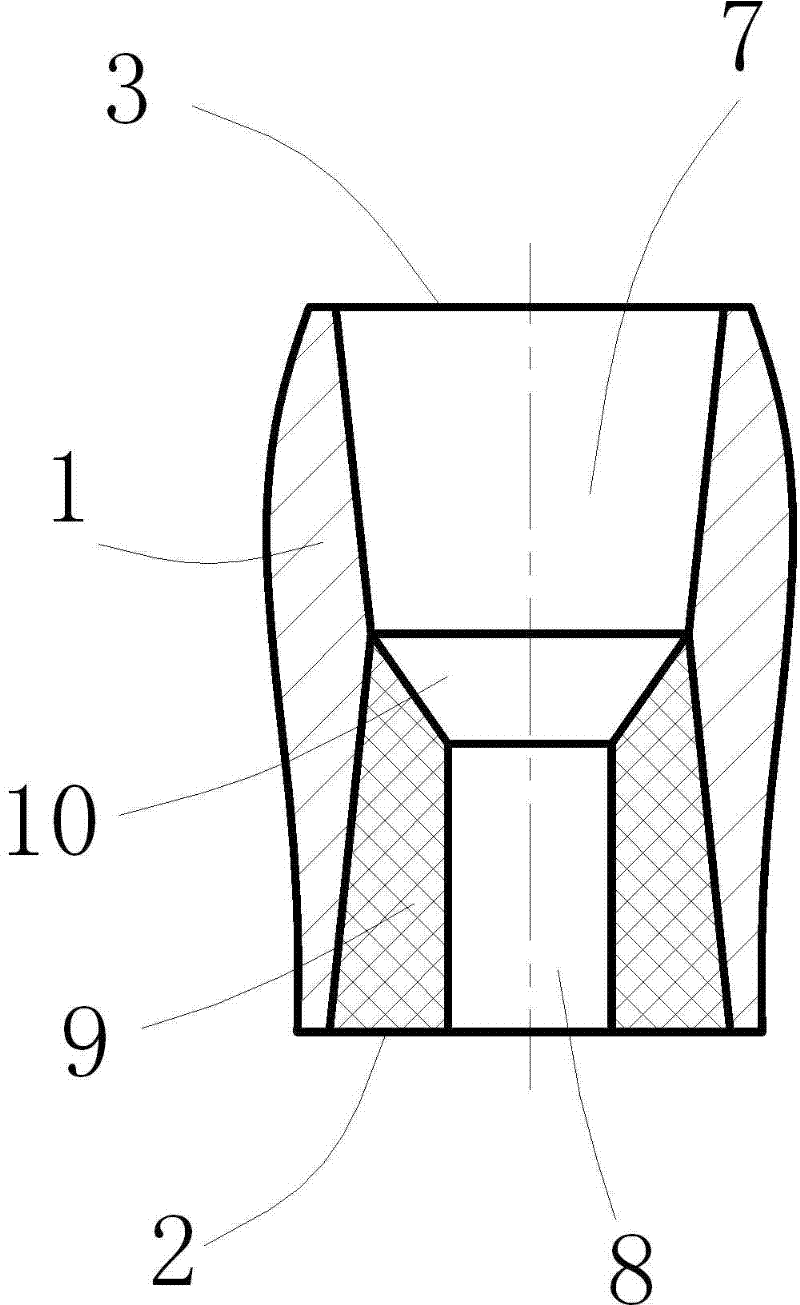

[0037] See attached figure 1 , for small holes with a hole depth of 30mm to 32mm and an aperture of 14mm to 16.5mm, the present invention provides a method for surfacing welding of small-diameter through-holes. The two ends of the workpiece 1 are respectively surfacing successively. The steps are as follows: The first end 2 of the workpiece 1 is to be surfacing and the first surfacing hole 4 is processed. The aperture is the size required for surfacing, and the hole depth is more than half of the depth of the small aperture to be surfacing. A through hole with a depth of 30mm Take the workpiece 1 as an example, the depth of the hole is 16mm to 18mm, and the maximum aperture is 15.5mm to 16.5mm; the second end 3 of the workpiece 1 is provided with a first vent hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com