Ultrasonic ball mill pulverizer

A crusher, ultrasonic technology, applied in the direction of grain processing, etc., can solve the problems of not being able to form a high-density energy field, fail to achieve nano-refining effect, fast decay of ultrasonic energy, etc., to eliminate local uneven concentration, easy to disassemble and repair Or replacement, the effect of preventing particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

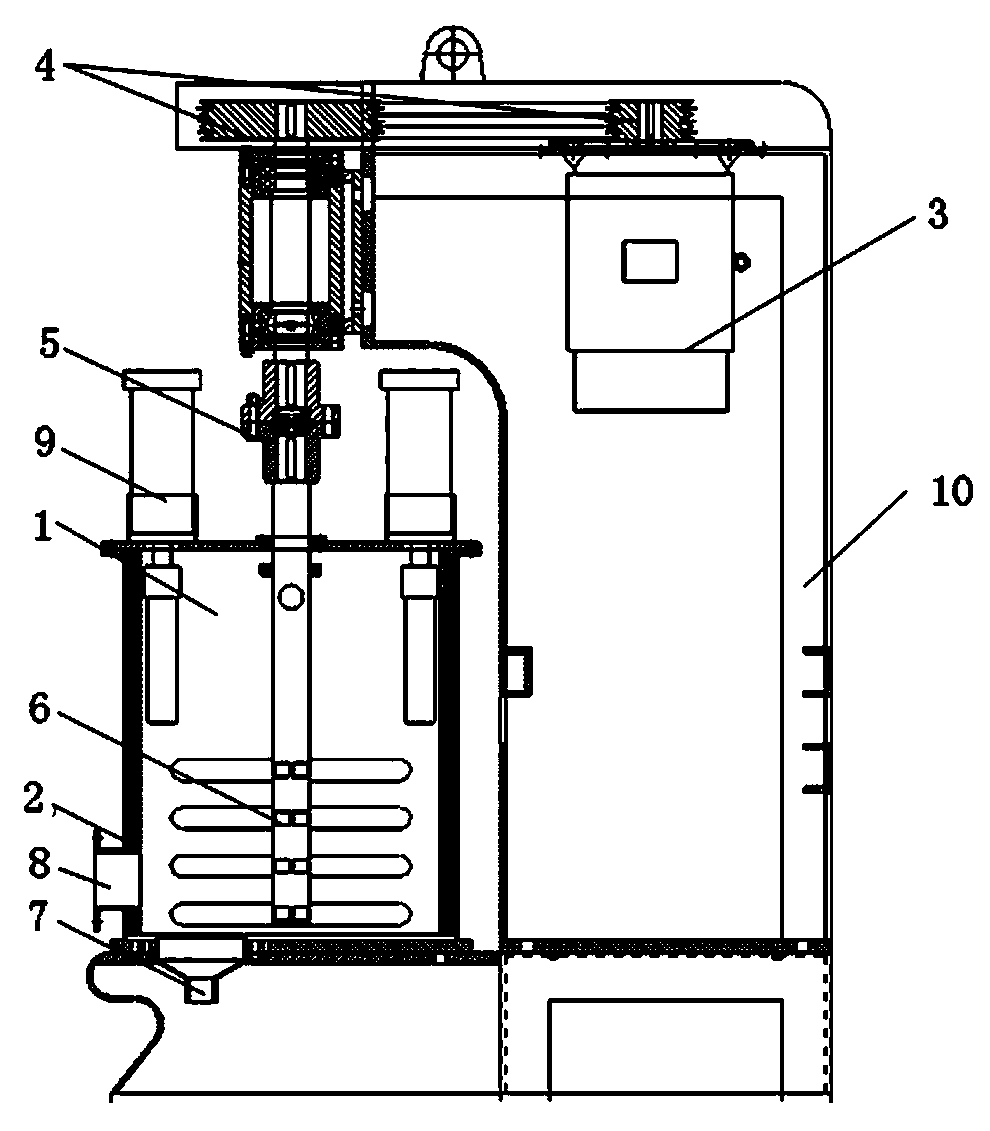

[0022] refer to figure 1 :

[0023] In this embodiment, the inner diameter of the mixing tank 1 used for holding materials is 500 mm, and the outer diameter is 560 mm. There is a cooling water jacket layer 2 between the inner and outer tanks, and a discharge port 7 and a volleyball hole 8 are arranged at the bottom of the tank.

[0024] The transmission motor 3 is fixed on the frame 10, and the motor 3 drives the stirring shaft 6 and the blade 7 in the mixing tank to rotate through the belt pulley 4 and the linkage shaft 5. The material of the stirring shaft in this embodiment is martensitic stainless steel; there are four stirring blades in total. The layer is threaded and welded, and the height of the stirring blade layer is 45mm. The mixing blade pushes several grinding balls placed in the mixing barrel to crush and grind the material; the material of the grinding balls is zirconia, and the average particle size is 2mm.

[0025] A total of 8 sets of ultrasonic horns of th...

Embodiment 2

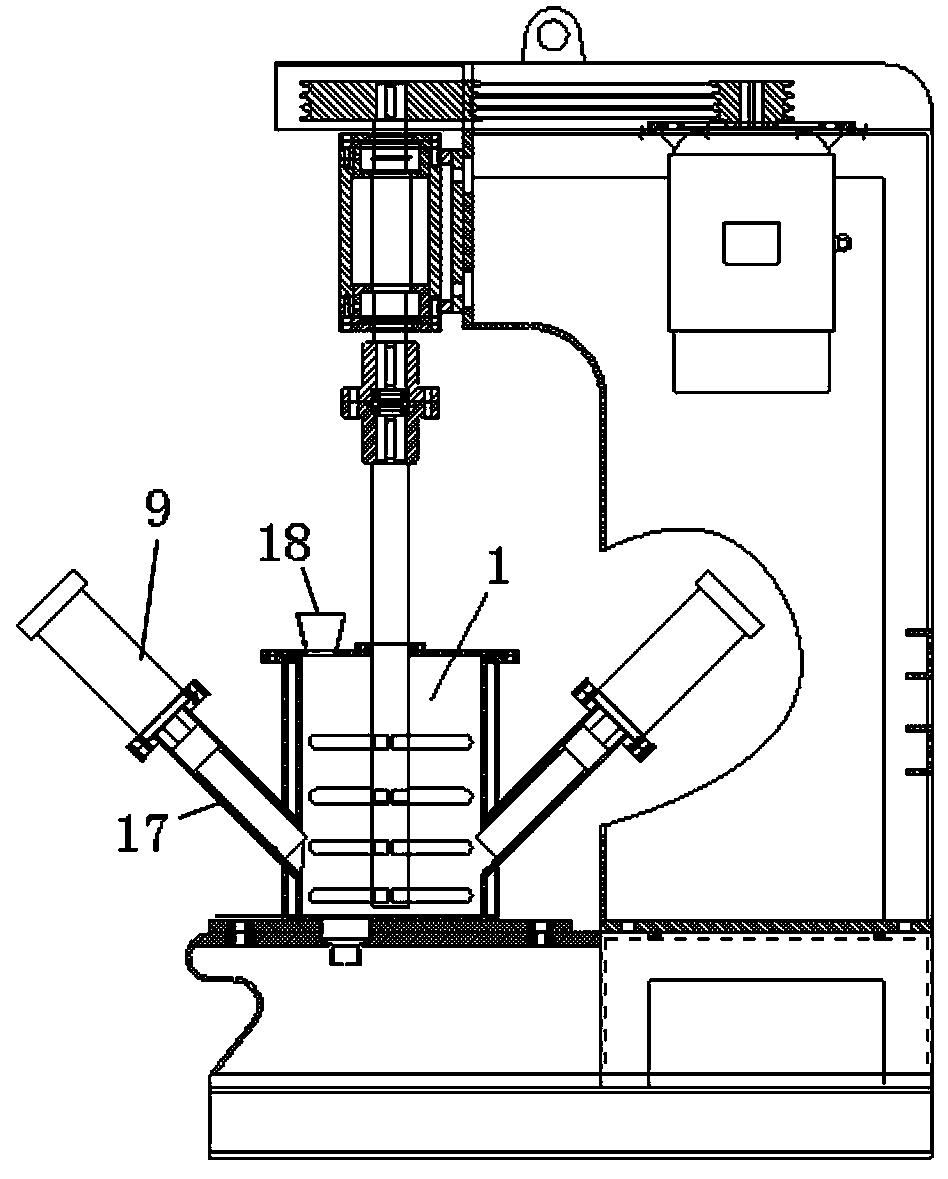

[0030] refer to image 3 and Figure 4 :

[0031] In this embodiment, the material enters the mixing tank from the feed port 18; the four ultrasonic generators 9 are installed on the hole in the wall of the mixing tank 1 and the installation boss 17 through the flange inclined at 45 degrees, and the ultrasonic waves in the direction of 45 degrees are inclined to the material. Energy field effect. In this example, after 12 hours of continuous work, 2 kg of tungsten disulfide or molybdenum disulfide powder with an average particle size of 4-5 μm can be crushed to an average particle size of about 0.6 μm, and the proportion of particles with a particle size below 100 nm reaches about 20%.

Embodiment 3

[0033] refer to Figure 5 :

[0034] The difference between this embodiment and Embodiment 1 is: 4 ultrasonic horns are installed vertically on the lid of the mixing tank, the distance between the tool head and the bottom of the tank is 50 mm, and the 4 ultrasonic horns are installed on the tank wall with an inclination of 45°. The ultrasonic energy fields of the straight and inclined ultrasonic generators have a cross-converging effect on the material. In this example, after 12 hours of continuous work, 2 kg of tungsten disulfide or molybdenum disulfide powder with an average particle size of 4-5 μm can be crushed to an average particle size of about 0.3 μm, and the proportion of particles with a particle size below 100 nm reaches about 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com