Electrostrictive reversible hydrogen storage method

A stretching and hydrogen storage technology, applied in the direction of structural parts, circuits, electrical components, etc., can solve the problems of difficult hydrogen release temperature and lowering, achieve the effect of reversible process, lower hydrogen storage and hydrogen release temperature, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

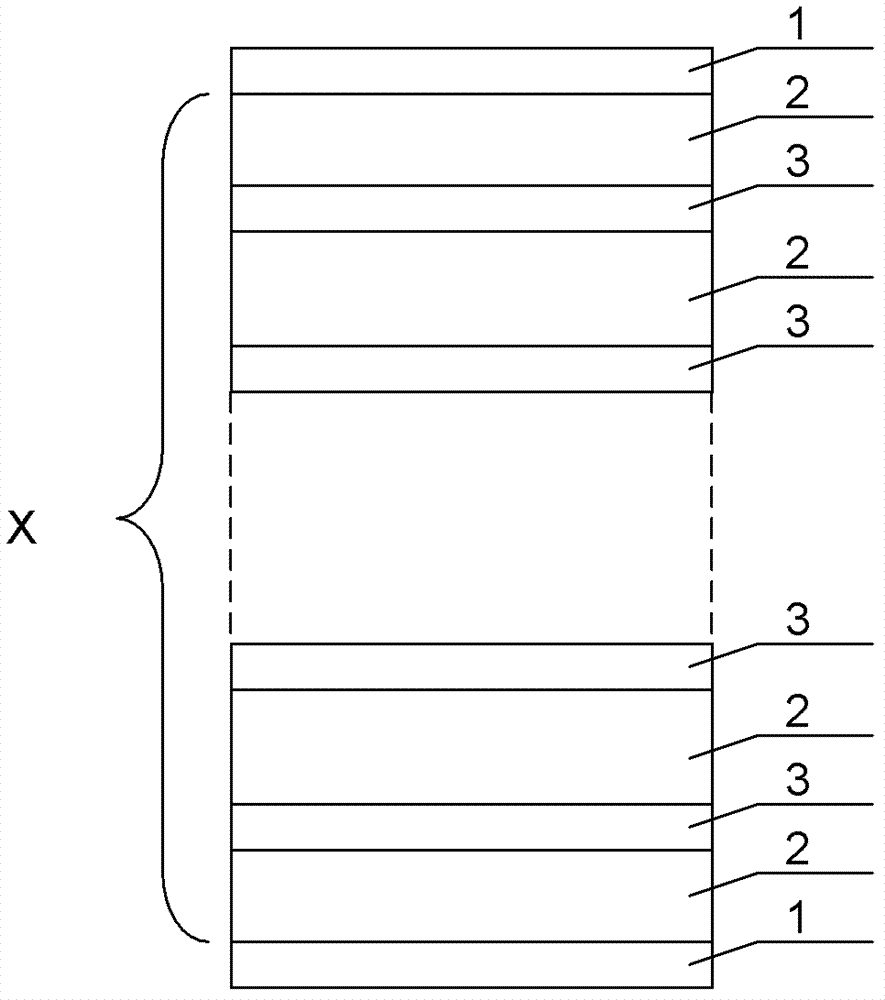

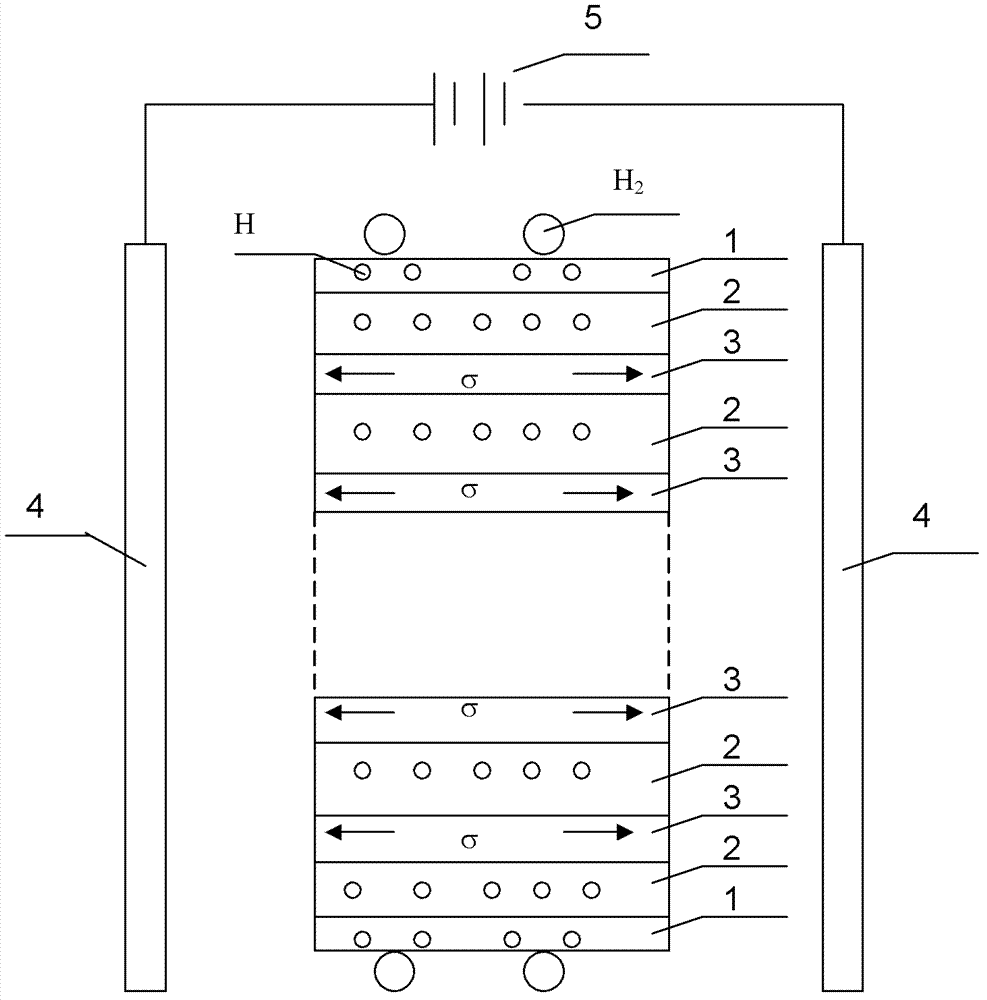

[0011] The present invention constitutes a hydrogen storage / hydrogen release system by hydrogen storage materials and an external electric field, the system has a multi-layer sandwich structure, wherein: the surface layer is made of molecular hydrogen H 2 Catalyst film 1 decomposed into atomic hydrogen H, such as pure Pt, pure Pd, Pt alloy or Pd alloy film, with a thickness of about 5-50 nm; the second layer is a pure Mg film or Mg-based low alloy film 2, with a thickness of about 5-500 nm, the alloy elements of Mg-based multi-element low-alloy thin film can be one or more of Nb, Ti, V, Ni, and the total alloy content is 0-20 wt.%. The third layer is electrostrictive material Thin film 3, with a thickness of about 5-500 nm, can be lead magnesium niobate (PMN), lead magnesium niobate-lead titanate (PMN-PT) or lead lanthanum zirconate titanate (PLNZT); the second and third layers of film. An electric field with variable direction and size is added to the multi-layer sandwich st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com