Method for preparing oligosaccharide and paper pulp

A technology of xylooligosaccharides and pulp, which is applied in the direction of pulping with inorganic alkali, pretreatment with alkaline compounds, fermentation, etc., can solve the problems of pulp and black liquor performance of unlisted xylose preparation methods, and achieve fiber quality And the effect of improving the physical performance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

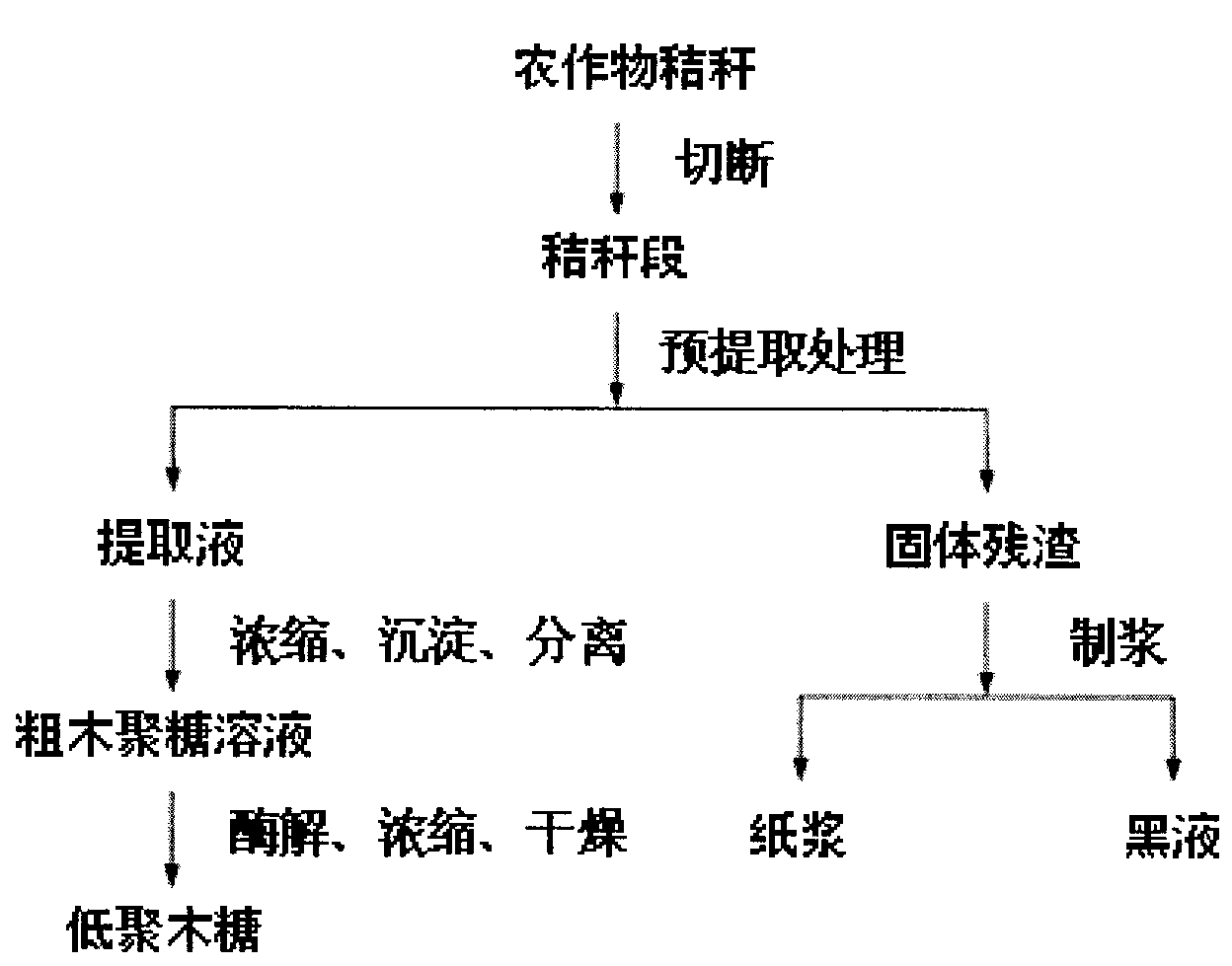

Image

Examples

Embodiment 1

[0023] Embodiment 1: take wheat straw as raw material to prepare xylo-oligosaccharide and paper pulp

[0024] step:

[0025] 1) Cut the wheat straw to 3-5cm, add 1.2kg of dry material to the reaction kettle, then add sodium hydroxide accounting for 5% of the dry material, and add water to make the ratio of the total liquid to the dry material 5:1, rotate the reactor to mix the materials evenly. Start timing at 50°C, raise the temperature to 130°C within 1 hour, and keep warm at this temperature for 0.5 hours before the pretreatment is completed. Separate the pre-extract and solid residue.

[0026] 2) The obtained pre-extraction is concentrated to about 10% of the total solids concentration with a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 10,000, and then evaporated to about 40% of the total solids concentration using a vacuum evaporator; Adjust the pH value to 6 with acetic acid, add the same volume of 95% ethanol, through precipitation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com