Preparation method of polypyrrole functional mediator doped with water-soluble anthraquinone or naphthoquinone compound and application thereof

A compound and water-soluble technology, applied in the field of preparation of polypyrrole functional mediators, can solve the problems of restricting catalytic performance and low doping, and achieve the effects of reducing secondary pollution, good stability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

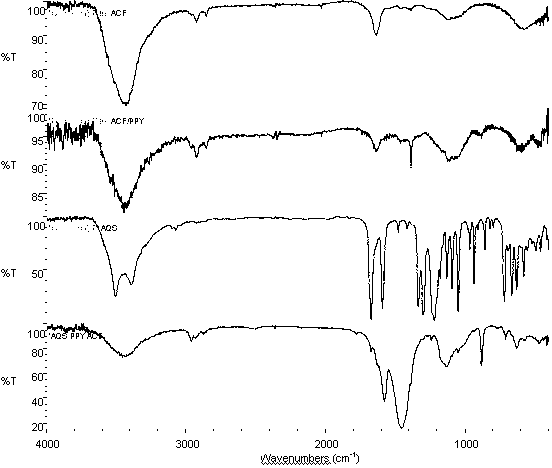

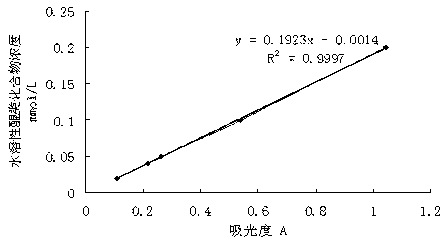

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of polymerization solution

[0033] Get 150mL double-distilled water in a 200mL beaker, add 1.1818g anthraquinone-2-sodium sulfonate to dissolve, and make a concentration of 0.024mol / l anthraquinone-2-sodium sulfonate solution, then adjust the pH with dilute sulfuric acid to 3. Then add 1 mL of pyrrole, stir for 5 minutes, and mix well; among them, pyrrole needs to be distilled twice before polymerization to remove impurities formed by oxidation in the air.

[0034] (2) Pretreatment of activated carbon felt and platinum electrode

[0035] Activated carbon felt: Cut the activated carbon felt into felt pieces with a side length of 3cm×3cm, soak and wash with deionized water three times, dry at 110~120°C, and store for later use;

[0036] Platinum sheet electrode: put the platinum sheet electrode into nitric acid solution with a volume ratio of 1:1 and 1mol / L NaOH solution in turn for 5 minutes each; then ultrasonically clean it in double distilled water, ...

Embodiment 2

[0086] (1) Preparation of polymerization solution

[0087] Get 150mL double-distilled water in a 200mL beaker, add 1.1818g anthraquinone-1-sodium sulfonate to dissolve, and make a concentration of 0.024mol / l anthraquinone-1-sodium sulfonate solution, then use dilute sulfuric acid to adjust the pH to 5. Then add 0.5mL pyrrole, stir for 5 minutes, and mix well; among them, pyrrole needs to be distilled twice before polymerization to remove impurities formed by oxidation in the air.

[0088] (2) Carry out pretreatment to activated carbon felt and platinum electrode, same as embodiment 1.

[0089] (3) Embed the pretreated platinum sheet electrode in step (2) into the activated carbon felt, and then insert it into the 200mL beaker containing the polymerization solution described in step (1), and use cyclic voltammetry to analyze The polymerization solution of sodium anthraquinone-1-sulfonate is subjected to cyclic voltammetry electrochemical polymerization, and the electrochemical...

Embodiment 3

[0095] (1) Preparation of polymerization solution: The difference from Example 1 is that 1.1932 g of sodium anthraquinone-1,5-disulfonate was weighed, the pH was adjusted to 7, and 1 mL of pyrrole was added.

[0096] (2) Carry out pretreatment to activated carbon felt and platinum electrode, same as embodiment 1.

[0097] (3) The difference from Example 1 is that the cyclic voltammetric electrochemical polymerization is carried out on the polymerization solution of sodium anthraquinone-1,5-disulfonate by cyclic voltammetry, and the electrochemical polymerization conditions are: polymerization potential: 0.30~ 0.50V; polymerization time: 1h; potential change rate: 0.03V / s.

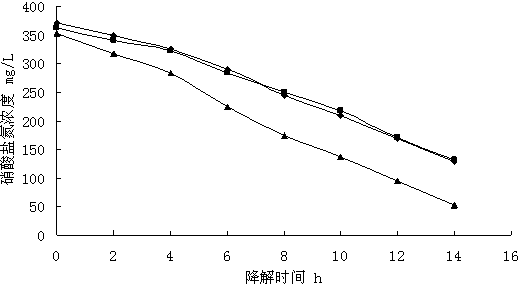

[0098] Then, according to the steps of Example 2, the degradation test of nitrate and nitrite was carried out on the activated carbon felt doped with anthraquinone-1,5-sodium disulfonate prepared in this example, and the results can be found in Figure 11 and Figure 12 : Activated carbon felt doped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com