A kind of led device without gold wire

An LED device, no gold wire technology, applied in the field of flip-chip light-emitting diode devices, can solve the problems of complex process, affecting production efficiency, production difficulty, etc., to achieve the effect of enhancing light-emitting effect, improving production efficiency, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

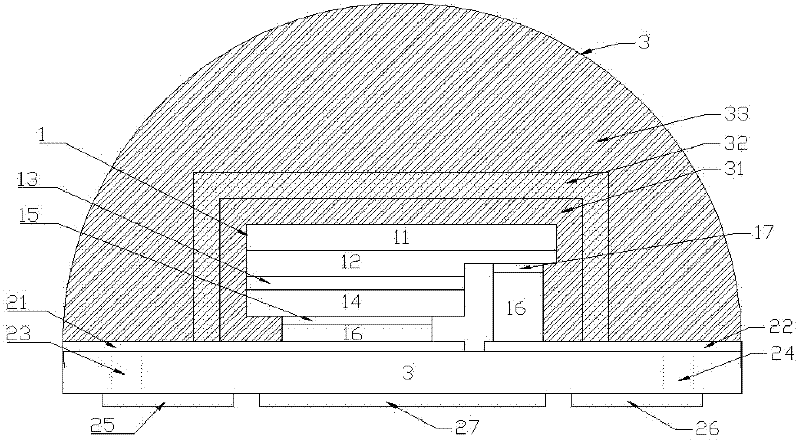

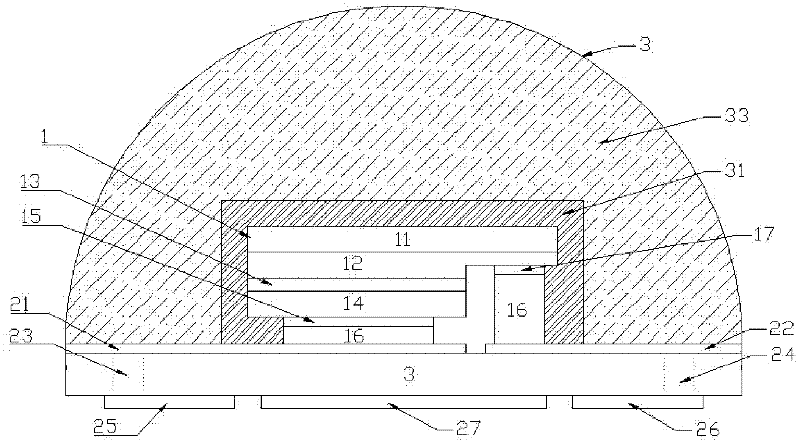

[0049] Such as figure 1 As shown, a gold-wire-free LED device includes an LED chip 1 , a substrate 2 and a packaging structure 3 . The LED chip 1 is flip-chip mounted on the substrate 2 , and the encapsulation structure 3 is disposed on the substrate 2 and surrounds the LED chip 1 .

[0050]The LED chip 1 includes a sapphire substrate 11 , an N-type GaN 12 , a light emitting layer 13 , a P-type GaN 14 , a P electrode 15 , a metal bump 16 and an N electrode 17 . N-type GaN 12 is grown on the sapphire substrate 11 , a light-emitting layer 13 is grown on the N-type GaN 12 , and a P-type GaN 14 is grown on the light-emitting layer 13 . Through process steps such as photolithography, etching, metal layer deposition and passivation layer protection, and finally through the split process, P electrodes 15 and metal bumps 16 are formed on the P-type GaN 14 layer, and on the N-type GaN 12 N electrodes 17 and metal bumps 16 are formed on the LED chip, and the P electrodes 15 and N elec...

Embodiment 2

[0065] The difference between embodiment 2 and embodiment 1 is that the shape of the optical structure layer 33 in the package structure 3 in embodiment 2 is a square structure. The optical structure layer 33 is used to adjust the external shape, and can meet different optical requirements of the packaging structure, and its material can be one or a combination of PC, PMMA, Silicone, EP, PET, and glass. The square shape structure can be made into a small volume and easy to shape.

Embodiment 3

[0067] The difference between embodiment 3 and embodiment 1 is that the optical structure layer 33 in the encapsulation structure 3 contains light conversion substances, and the light conversion substances are organic dyes, rare earth light-emitting organic complexes, YAG, LuAG, Silicate, (Ca , Sr)AlSiN 3 One or more mixtures, the light conversion substance and the optical structure layer material in liquid state are pre-mixed together, and then formed by coating, molding and other process steps. By mixing the light-converting substance into the optical structure layer 33, the functions of light conversion and designing the optical outer layer structure are realized at the same time, which greatly improves the production efficiency and reduces the production cost.

[0068] Compared with the prior art, the present invention flip-chips the LED chip 1 on the ceramic substrate 2, effectively improving the heat dissipation effect of the LED device. The first through hole 23 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com