A kind of method that calcium sulfate hemihydrate whisker prepares

A technology of calcium sulfate hemihydrate and calcium sulfate, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., can solve the problem of large solidification of α-calcium sulfate hemihydrate, low conversion rate, Low strength and other problems, to achieve the effect of high aspect ratio, uniform length and diameter, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Amorphous calcium sulfate preparation:

[0017] Prepare 750 ml each of 0.5 mol / L potassium sulfate and 0.5 mol / L calcium nitrate, mix them in a 2 L beaker, stir with electric power for 30 min, let stand for 24 h, filter, and store the obtained filter cake.

[0018] Determination of moisture content of filter cake:

[0019] Weigh a filter cake with a mass of about 1 g in a small crucible, calcined at 400 °C for 3 h, take it out and weigh it, and calculate its water content.

[0020] Preparation of α-calcium sulfate hemihydrate whiskers:

[0021] Dissolve amorphous calcium sulfate in deionized water, stir for 10 min, and ultrasonically disperse for 20 min to prepare 50 ml of calcium sulfate suspension with a mass fraction of about 5%. Move the suspension to a 100 ml high-pressure hydrothermal reactor, under saturated vapor pressure, the reaction temperature is 110 °C, and the reaction time is 6 h. Calcium sulfate hemihydrate whiskers.

[0022] Determination of water c...

Embodiment 2

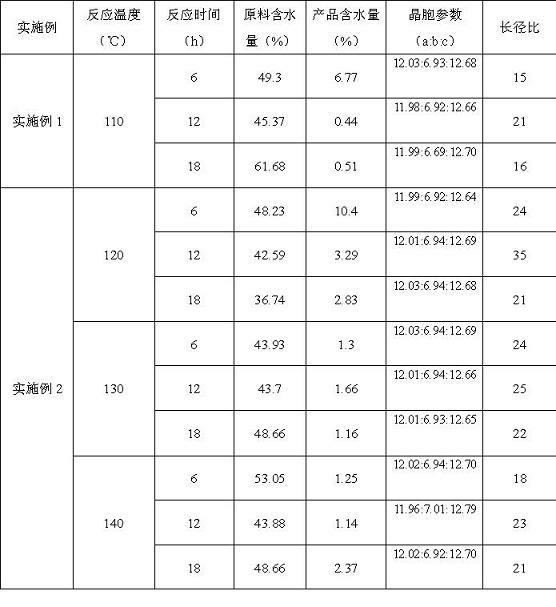

[0029] Same as Example 1, but changing the reaction temperature to 120°C, 130°C, and 140°C respectively, the results obtained are shown in Table 1.

[0030] It can be seen from Table 1 that the water content of the raw material amorphous calcium sulfate is between about 45% and 50%. When the reaction time was 12 h and the reaction temperature increased from 110°C to 140°C, the water content of the product first increased from 0.44% to 3.29%, then decreased from 3.29% to 1.14%, and the aspect ratio first increased from 21 to 35, and then reduced from 35 to 25, which shows that raising the reaction temperature is conducive to the increase of the aspect ratio of the product, but too high a reaction temperature makes the product easy to lose water, which is not conducive to the production of calcium sulfate hemihydrate, resulting in a decrease in the aspect ratio , so the optimum reaction temperature is 120 ℃.

[0031] In Example 2, when the reaction temperature is 120°C, the dry...

Embodiment 3

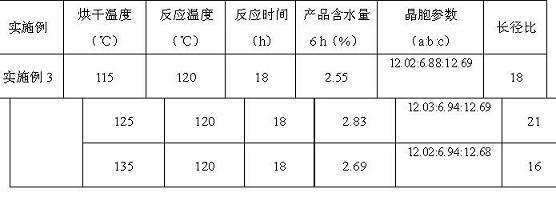

[0034] Same as in Example 1, but keep the reaction temperature at 120 °C, the reaction time at 18 h, the drying time at 6 h, and change the drying temperature to 115 °C and 135 °C respectively. The results are shown in Table 2.

[0035]

[0036] It can be seen from Table 2 that when the reaction temperature is 120 °C, the reaction time is 18 h, and the drying time is 6 h, when the drying temperature increases from 115 °C to 135 °C, the water content of the product first increases from 2.55% to 2.83%. As the drying temperature decreased to 2.69%, the increase in water content was due to the continuous transformation of amorphous calcium sulfate to calcium sulfate hemihydrate. The unit cell parameters a:b:c values are 12.02:6.88:2.69, and the α-calcium sulfate hemihydrate unit cell parameters a:b:c values are 12:6:12, which are close to it, indicating that the main product of the product It is α-calcium sulfate hemihydrate whiskers. The aspect ratios are 18, 21 and 16, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com