A special solvent-based primer for 3c product magnesium-aluminum alloy materials and preparation method thereof

A magnesium-aluminum alloy and solvent-based technology, applied in the field of solvent-based primers and their preparation, can solve the problems of expensive magnesium-aluminum alloy materials, cannot be easily scrapped, and high porosity, and achieves good interlayer adhesion and excellent resistance to boiling water. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

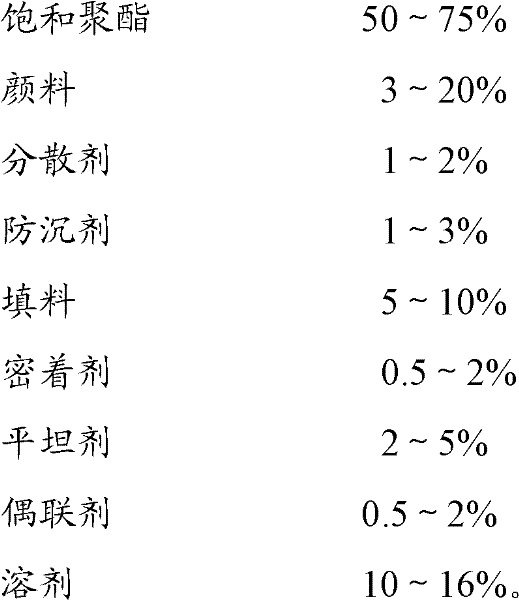

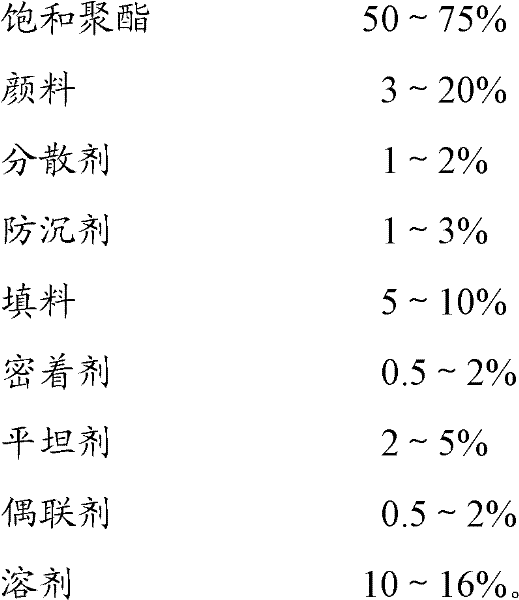

[0028] A special solvent-based black primer for magnesium-aluminum alloy materials of 3C products, calculated by weight percentage, including the following substances: saturated polyester (polymer polyester resin) 65%, pigment (carbon black) 3%, dispersant 1.8% , anti-settling agent (polyethylene wax) 1%, filler (aluminum tripolyphosphate) 10%, adhesive agent (bisphenol A epoxy resin) 1%, leveling agent (modified polysiloxane) 2%, even Joint agent (epoxy silane cocondensate) 0.5%, solvent 15.7%.

[0029] The method for preparing a special solvent-based black primer for magnesium-aluminum alloy materials of 3C products comprises the following preparation steps:

[0030] Step A, first mix the dispersant, pigment, 35% saturated polyester and 2% solvent of the amount, and stir at a high speed for 12 minutes at 1200rpm with a stirrer to obtain a uniformly dispersed mixed slurry I, then use sand The mill grinds the mixed slurry I to a fineness of less than 10 microns to obtain the ...

Embodiment 2

[0039] A special solvent-based black primer for magnesium-aluminum alloy materials of 3C products, calculated by weight percentage, including the following substances: saturated polyester (polymer polyester resin) 52%, pigment (carbon black) 20%, dispersant 1% , anti-settling agent (polyethylene wax) 3%, filler (aluminum tripolyphosphate) 5%, adhesive agent (bisphenol A epoxy resin) 2%, leveling agent (modified polysiloxane) 5%, even Joint agent (epoxy silane cocondensate) 2%, solvent 10%.

[0040] The method for preparing the solvent-based black primer dedicated to the magnesium-aluminum alloy material of the 3C product includes the following preparation steps:

[0041] Step A, first mix the dispersant, pigment, 20% saturated polyester and 2% solvent of said amount, and stir at a high speed for 15 minutes at 1000rpm with a stirrer to obtain a uniformly dispersed mixed slurry I, and then use sand The mill grinds the mixed slurry I to a fineness of less than 10 microns to obta...

Embodiment 3

[0048] A special solvent-based black primer for magnesium-aluminum alloy materials of 3C products, calculated by weight percentage, including the following substances: saturated polyester (polymer polyester resin) 59.5%, pigment (carbon black) 10%, dispersant 1.5% , anti-settling agent (polyethylene wax) 2.5%, filler (aluminum tripolyphosphate) 8%, adhesive (bisphenol A epoxy resin) 0.5%, leveling agent (modified polysiloxane) 3.5%, even Joint agent (epoxy silane cocondensate) 1%, solvent 5%.

[0049] The method for preparing the solvent-based black primer dedicated to the magnesium-aluminum alloy material of the 3C product includes the following preparation steps:

[0050] Step A, first mix the dispersant, pigment, 29.5% saturated polyester and 2% solvent of the amount, and stir at a high speed for 13 minutes at 1500rpm with a stirrer to obtain a uniformly dispersed mixed slurry I, then use sand The mill grinds the mixed slurry I to a fineness of less than 10 microns to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com