Oriented carbon nanotube/polymer composite film and its preparation method and application

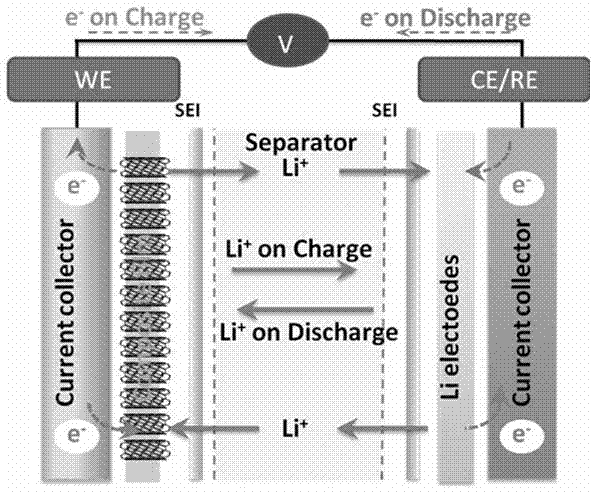

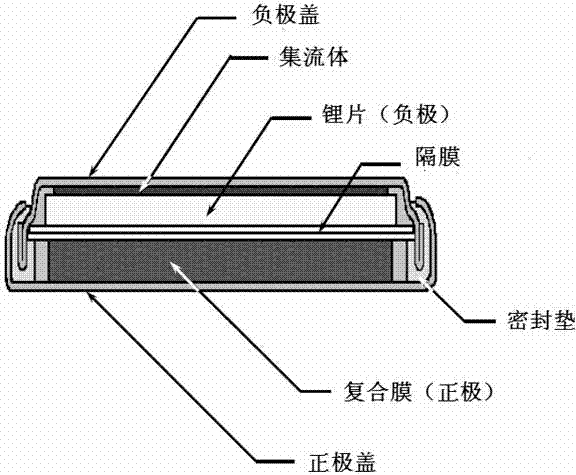

A technology of oriented carbon nanotubes and carbon nanotubes, applied in the field of lithium ion batteries, can solve problems such as unfavorable lithium intercalation and deintercalation, and achieve the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

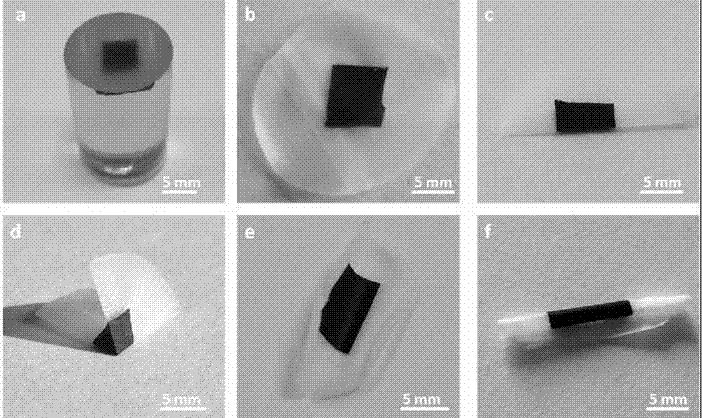

[0028] The specific process of preparation is as follows:

[0029] First, the synthesis of aligned carbon nanotube arrays.

[0030] Vertically grown carbon nanotube arrays with Fe(1nm) / Al 2 o 3 (10nm) / SiO 2 / Si as a catalyst was synthesized using typical chemical vapor deposition in a quartz tube of a tube furnace. Al in the catalyst 2 o 3 It is located in the middle of the silicon wafer and Fe, as a buffer layer, and Fe as a catalyst, which are prepared by depositing a nanometer-thick film on a silicon wafer by an electron beam evaporation coating device. Using chemical vapor deposition method, ethylene is used as carbon source, argon and hydrogen are used as carrier gas, and highly oriented carbon nanotube arrays are synthesized on Si substrate with oxide layer. The details of the synthesis and the self-assembly of carbon tubes in fibers can be referred to the existing literature reports.

[0031] Second, preparation of embedding stock solution.

[0032] The formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com